Inflating device for gas packaging bag

An inflatable device and packaging bag technology, applied in the direction of pressurized/gasified packaging, etc., can solve the problem of reducing work efficiency and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

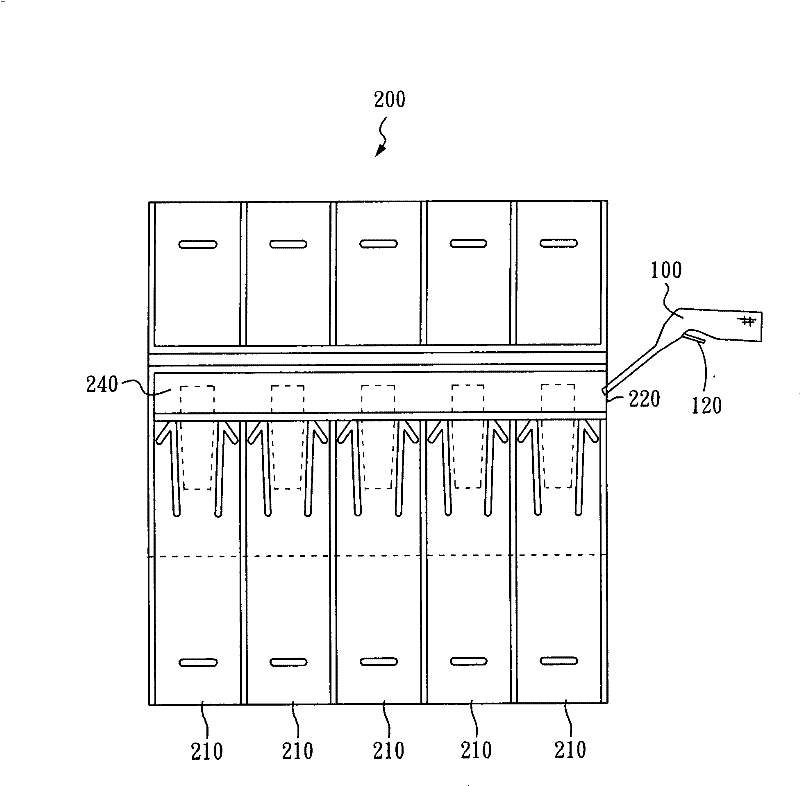

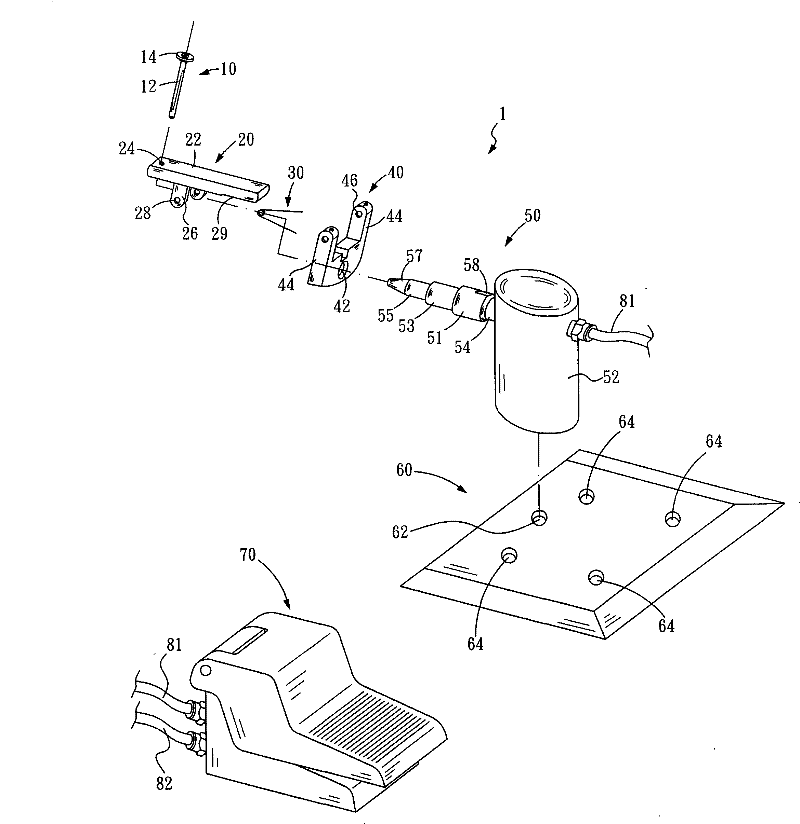

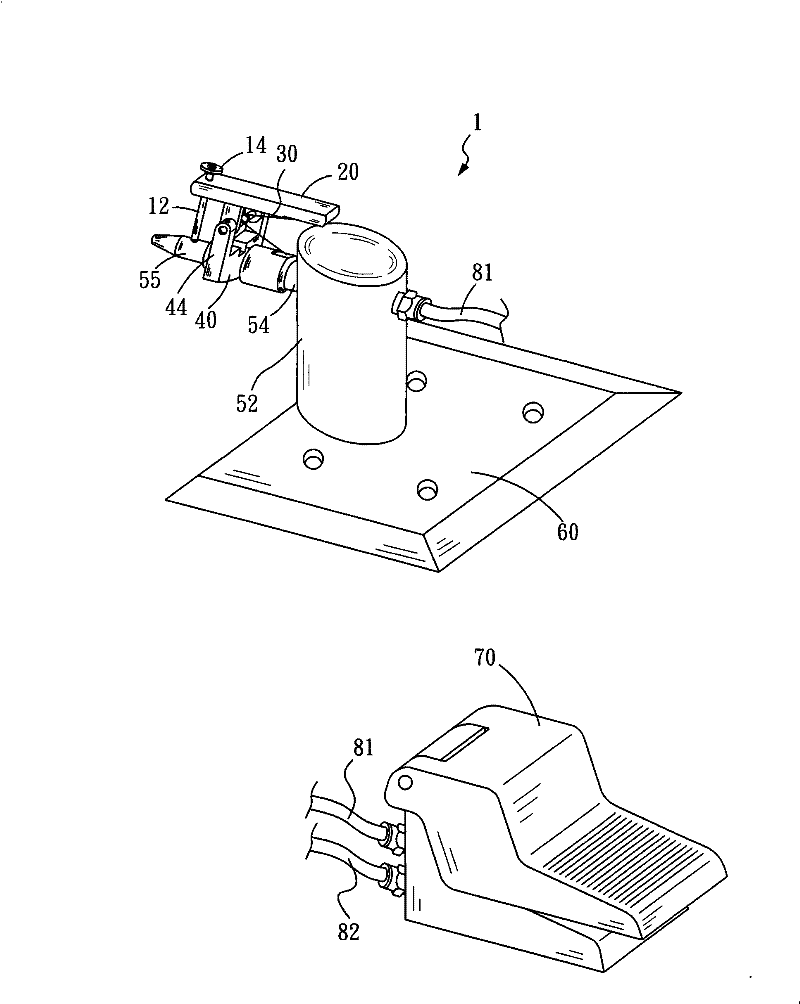

[0022] Example 1, an inflation device for gas packaging bags, please refer to figure 2 , Is a three-dimensional exploded schematic diagram of the inflator 1. The inflator 1 includes: a buckle member 10, a control member 20, a control spring 30, a shaft base 40, a support base 50, a fixed base 60, and a control pedal 70. The buckle member 10 has a round rod 12, and a round disk 14 is screwed on the top of the round rod 12, and the diameter of the round disk 14 is much larger than the round rod 12. The manipulating member 20 has a plate 22, and the left end of the plate 22 is provided with a perforation 24. The diameter of the perforation 24 is the same as the diameter of the rod 12 of the buckling member 10, which is just for the rod 12 to pass through. A pair of ear seats 26 are provided on both sides of the bottom of a third part of the plate 22 near the perforation 24, and the bottom end of the ear seats 26 is provided with a shaft hole 28. In addition, the bottom of the pl...

Embodiment 2

[0025] Example 2, please refer to Figure 5 , Is a three-dimensional exploded schematic diagram of Embodiment 2 of the present invention. The inflator 1 includes: a buckle member 10, a control member 20, a control spring 30, a shaft base 40, a support base 50, a fixing base 60, a control pedal 70, and a clamping member 90. The buckling member 10, the control member 20, the control spring 30, the shaft base 40, the support seat 50, the fixing seat 60, and the control pedal 70 are substantially the same as those of the aforementioned embodiment 1. The main difference is that the buckle member 10 The round rod 12 is shorter, and a round hole 16 is provided at the bottom end of the round rod 12. In addition, a clamping member 90 is provided. The clamping member 90 has left and right clamping seats 91, 92, each of the left and right clamping seats 91, 92 forms a semicircular curve. The diameter of the small rod 55 of the air outlet member 54 of the seat 50 is the same. The top si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com