Air packing bag with five-layer structure and manufacturing method thereof

A manufacturing method and air packaging technology, applied in the direction of transportation and packaging, to prevent mechanical damage, containers, etc., can solve the problems of inconvenient opening, difficult opening of the inflation port, and insufficient airflow, so as to ensure quality stability and reduce Packaging time and cost saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

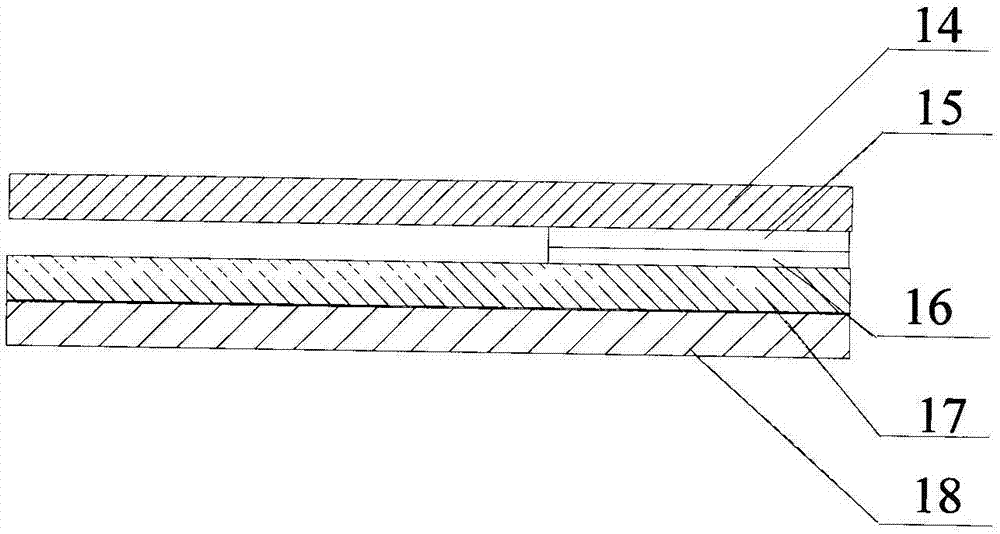

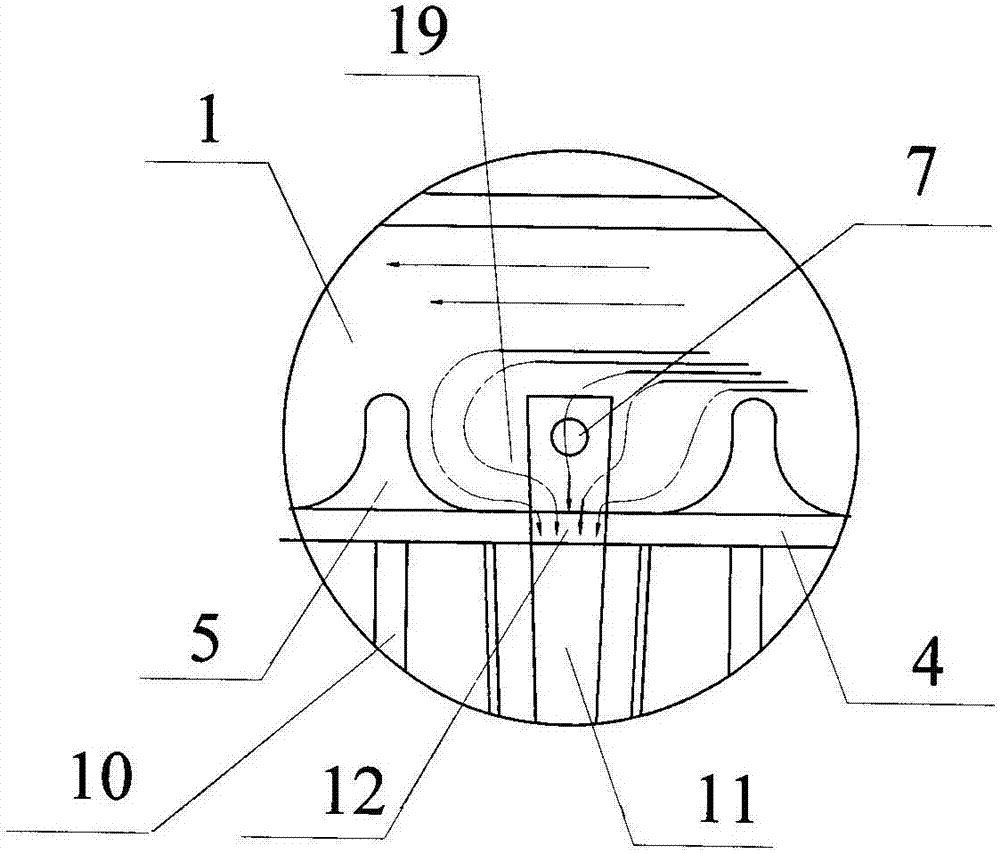

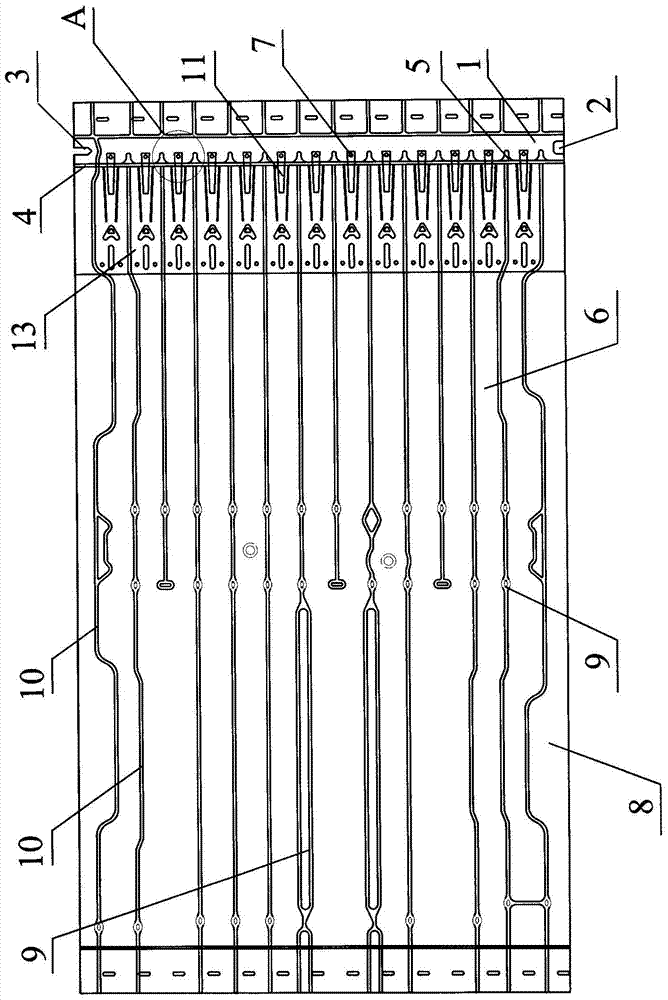

[0051] Such as Figure 1 ~ Figure 3 As shown, a five-layer structure air-packing bag, the air-packing bag is formed by folding and heat-sealing a five-layer packaging film, and the packaging film includes an upper thermoplastic film layer 14, an upper air valve film 15 and a lower air valve Film 16 constitutes one-way valve film layer, lower floor thermoplastic film layer 17 and one deck functional film layer 18, and functional film layer 18 is located at the outer side of lower floor thermoplastic film layer 17, wherein, upper and lower two layers of thermoplastic film layers and The one-way valve film layer is heat-sealed to form a plurality of independent sealed air chambers 6 and one-way valves 13, and an air intake channel 1, each sealed air chamber 6 communicates with the air intake channel 1 through the one-way valve 13, and the air intake An air guiding device 5 formed by heat sealing is provided at the junction of the heat sealing line 4 under the channel and the heat...

Embodiment 2

[0061] An air-packing bag with a five-layer structure. The air-packing bag is formed by folding and heat-sealing a five-layer packaging film. The packaging film includes two upper and lower thermoplastic film layers, two middle layers of one-way valve film layers, and a layer of The functional film layer, the lower thermoplastic film layer is combined with the functional film layer to form the lower composite thermoplastic film layer, which is the lower thermoplastic film layer coated with an aluminum film on the outer surface.

[0062] The upper and lower thermoplastic film layers and two layers of one-way valve film layers are heat-sealed to form two independent sealed air chambers and one-way valves, as well as an air inlet channel, each sealed air chamber passes through the one-way valve and the air inlet The channel is connected, and an air guiding device formed by heat sealing is provided at the intersection of the heat sealing line under the air intake channel and the he...

Embodiment 3

[0070] An air-packing bag with a five-layer structure. The air-packing bag is formed by folding and heat-sealing a five-layer packaging film. The packaging film includes two upper and lower thermoplastic film layers, two middle layers of one-way valve film layers, and a layer of The functional film layer, the lower thermoplastic film layer and the functional film layer are combined to form the lower composite thermoplastic film layer, which is the lower thermoplastic film layer coated with paint on the outer surface.

[0071] The upper and lower thermoplastic film layers and two layers of one-way valve film layers are heat-sealed to form 80 independent sealed air chambers and one-way valves, as well as an air intake channel. The channel is connected, and an air guiding device formed by heat sealing is provided at the intersection of the heat sealing line under the air intake channel and the heat sealing line of the sealed air chamber. The air guiding device is in the shape of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com