Mounting method for underbeam segment of large-stride steel box girder stayed-cable bridge

A technology for cable-stayed bridge towers and installation methods, which is applied to bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of impractical implementation and high construction costs, and achieve small construction conditions, economical convenience, and simple and practical installation methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

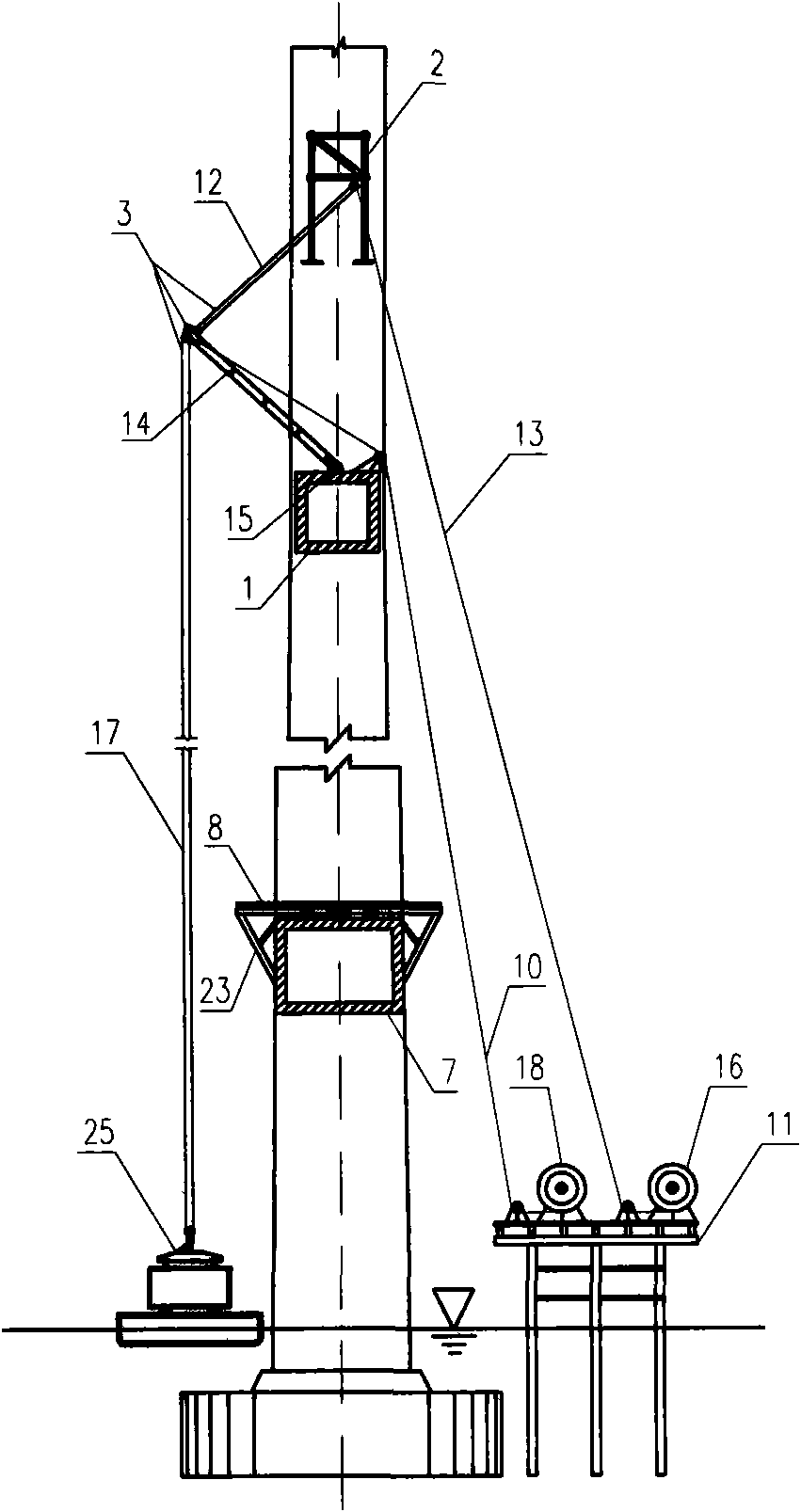

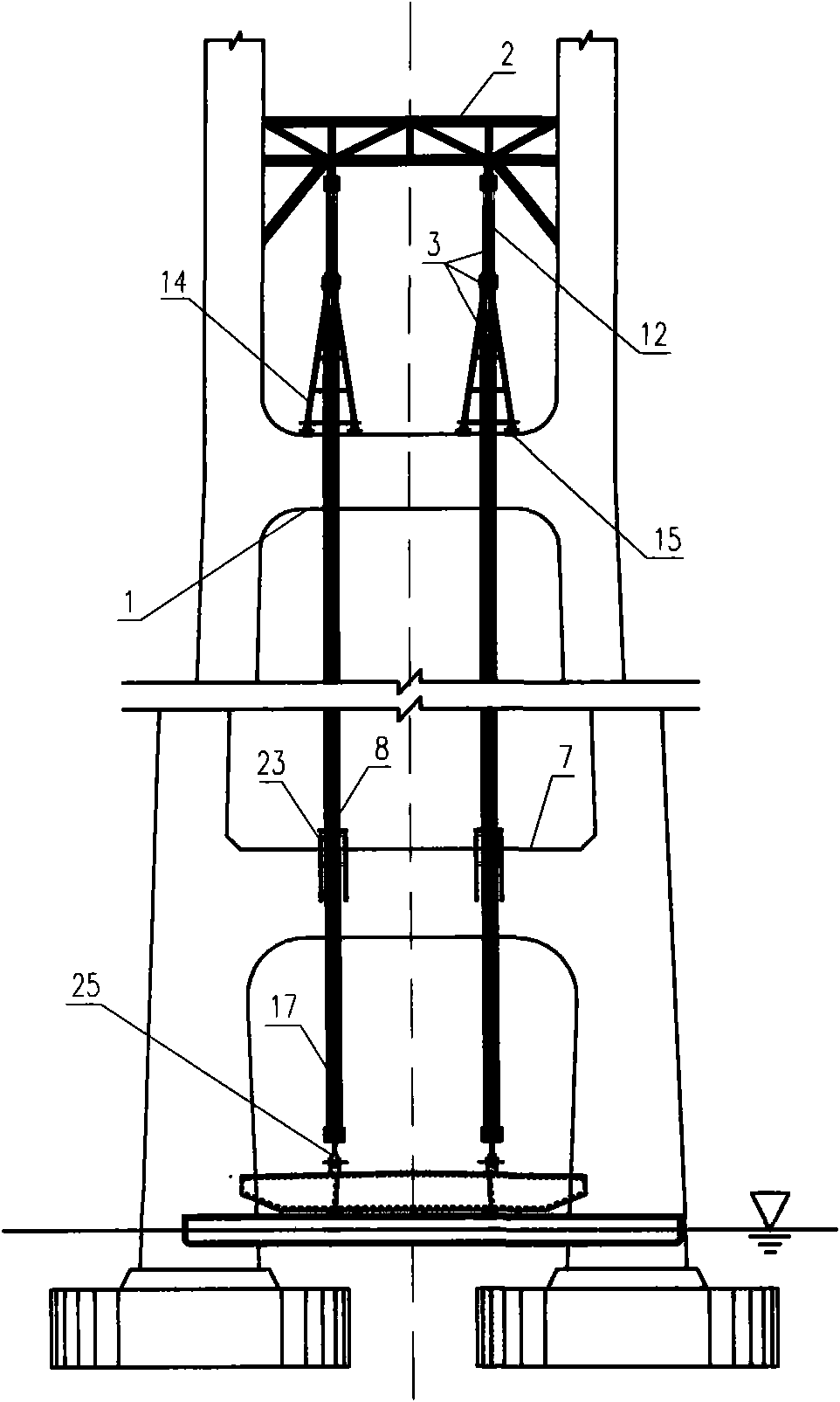

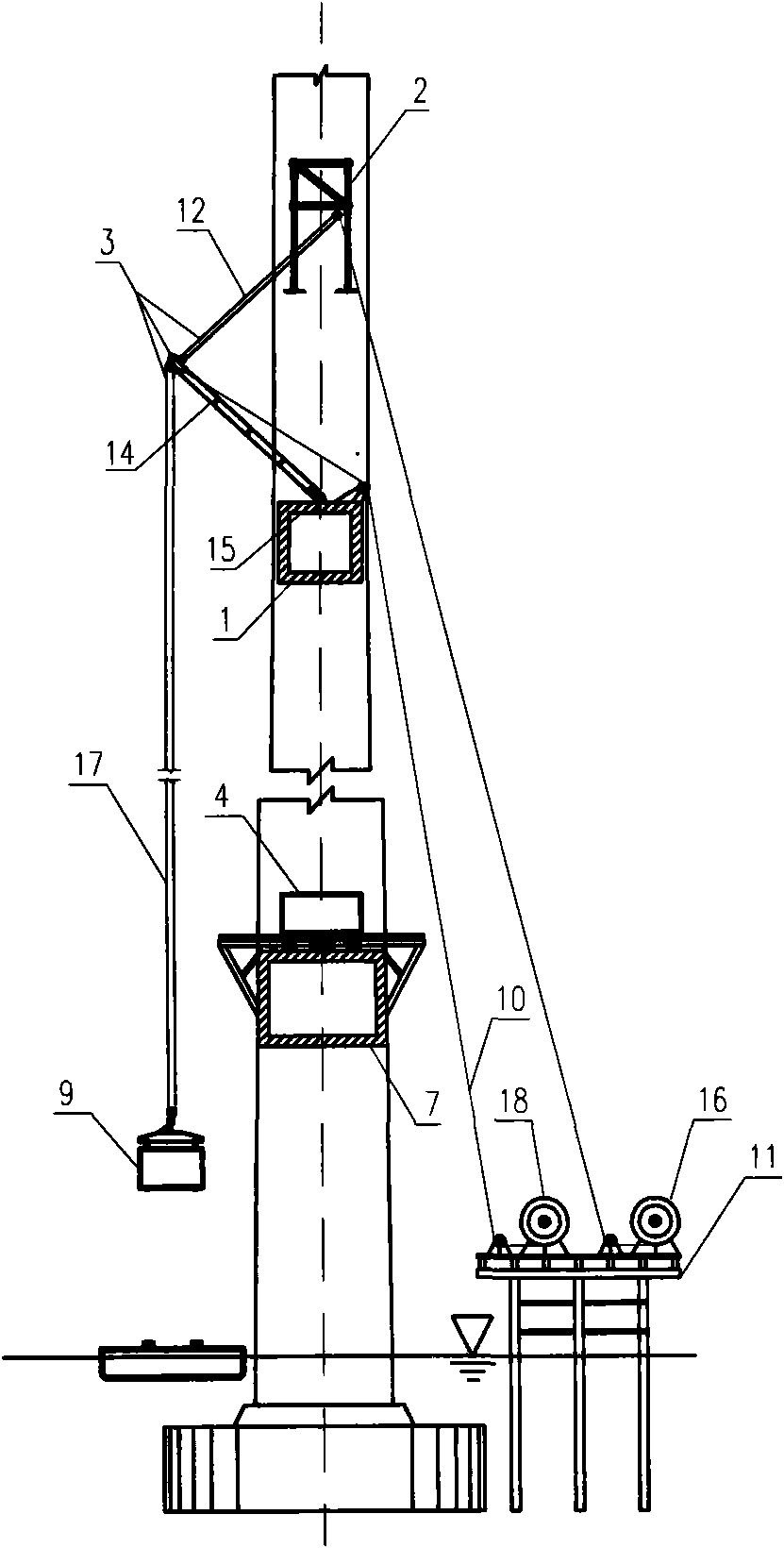

[0039] like Figure 1-12 Shown, the construction steps of the installation method of the tower lower girder section of the long-span steel box girder cable-stayed bridge of the present invention are:

[0040] (1) set up the mast type crane 3 and lift the steel box girder 4, 9, 24 in the tower area by means of the construction wind mechanism 2 used during the cable tower upper beam 1 and cable tower construction,

[0041] (2) Install deck cranes 5 and 19 on the steel box girders 4, 9 and 24 in the tower area to lift the first standard beam sections 6 and 20 adjacent to the steel box girders 4 and 24 in the tower area,

[0042] (3) Install the deck cranes 5 and 19 symmetrically on the installed first section standard beam sections 6 and 20, and start the symmetrical hoisting of the standard beam sections 21 and 22 on the river center side and shore side.

[0043] The construction steps of the installation method of the lower girder section of the above-mentioned long-span steel...

Embodiment 2

[0058] Except: E. Lift the first standard beam section 20 of the shore side with the bridge deck crane 5 installed in place, install it in place and complete the hanging cable; G. Lift the first standard beam section 20 of the river center side and place it Complete hanging rope, H, bridge deck crane 5 walks on the first joint standard beam section 6 of the river center side, I, bridge deck crane 19 is installed on the bank side first joint standard beam section 20, start the river center side Except for the symmetrical hoisting construction of the standard beam sections 21 and 22 on the shore, the rest are the same as in Embodiment 1.

Embodiment 3

[0060] Except: mast 14 is the steel mast that is installed on the cable tower upper beam 1, all the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com