Short-loop optical fiber gyroscope

A fiber optic gyroscope, short loop technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

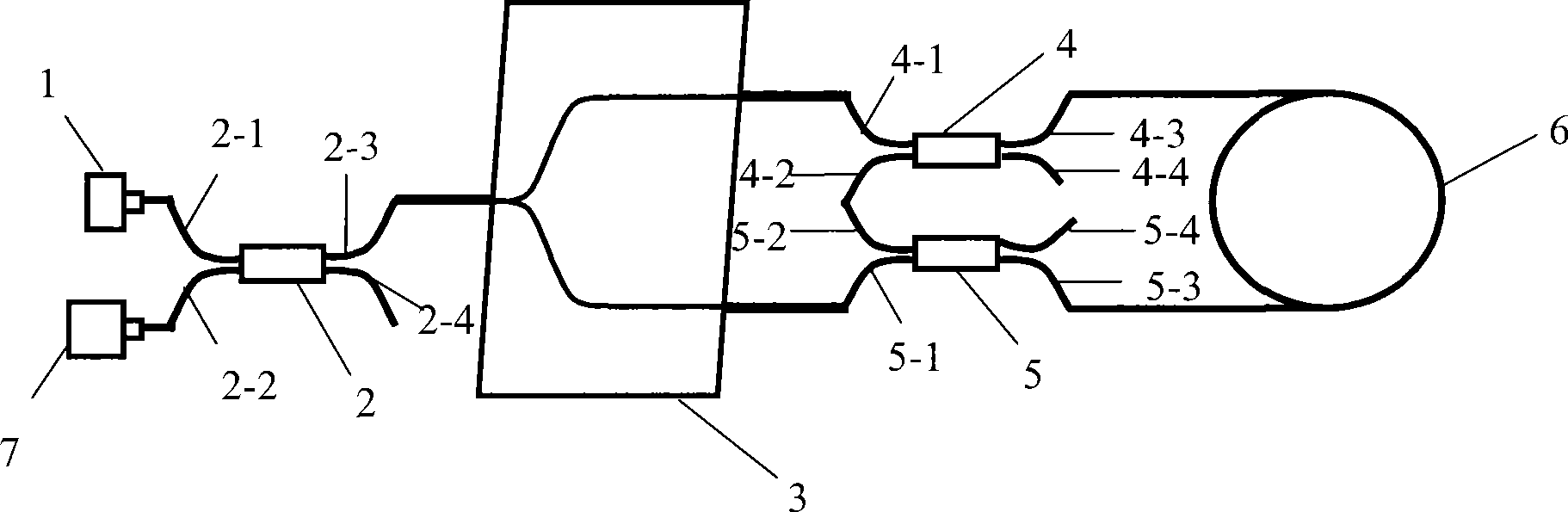

[0012] Such as figure 1 As shown, a short-ring fiber optic gyroscope includes a broadband light source 1 , a first coupler 2 , a Y waveguide 3 , a second coupler 4 , a third coupler 5 , an optical fiber ring 6 , and a detector 7 .

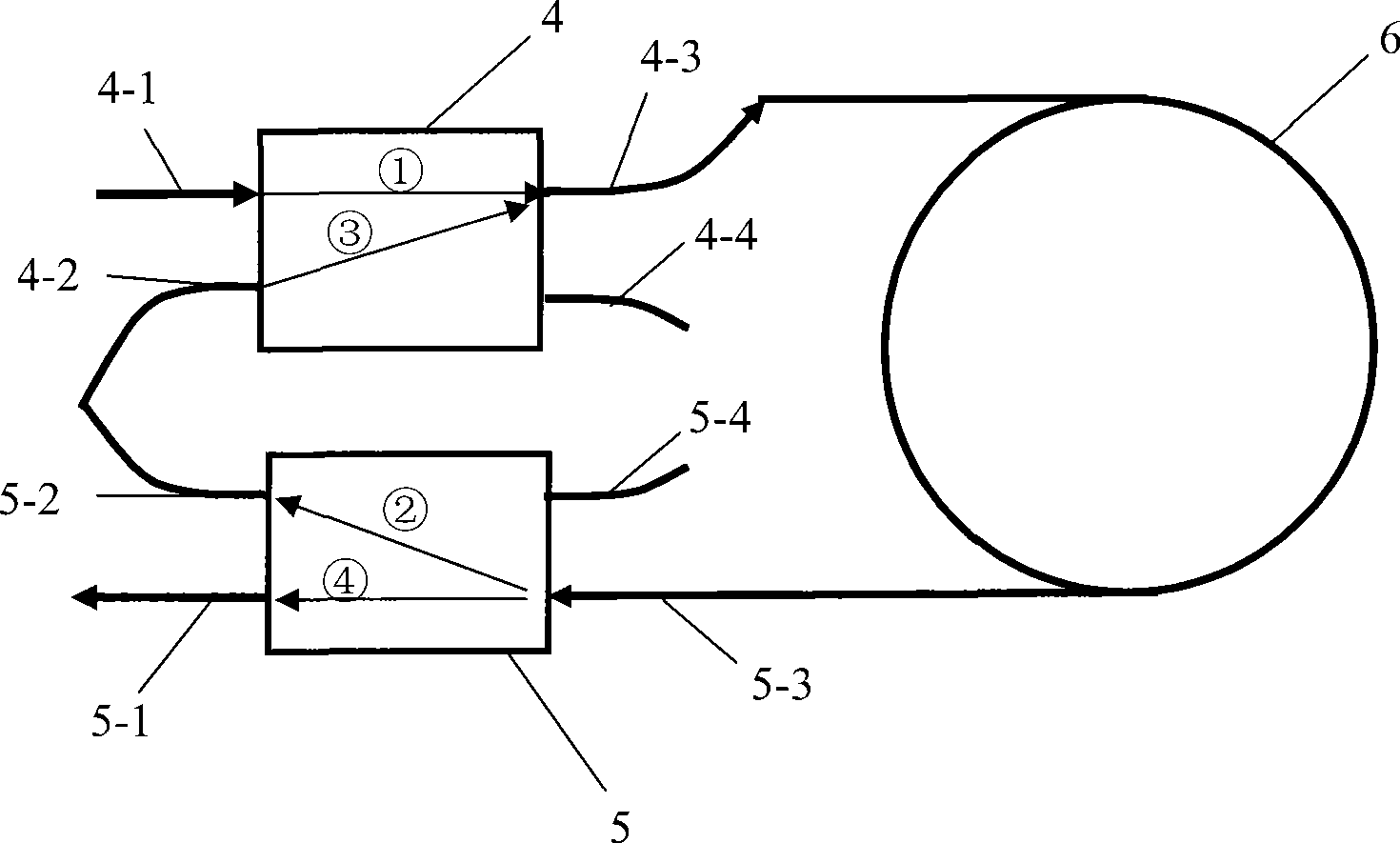

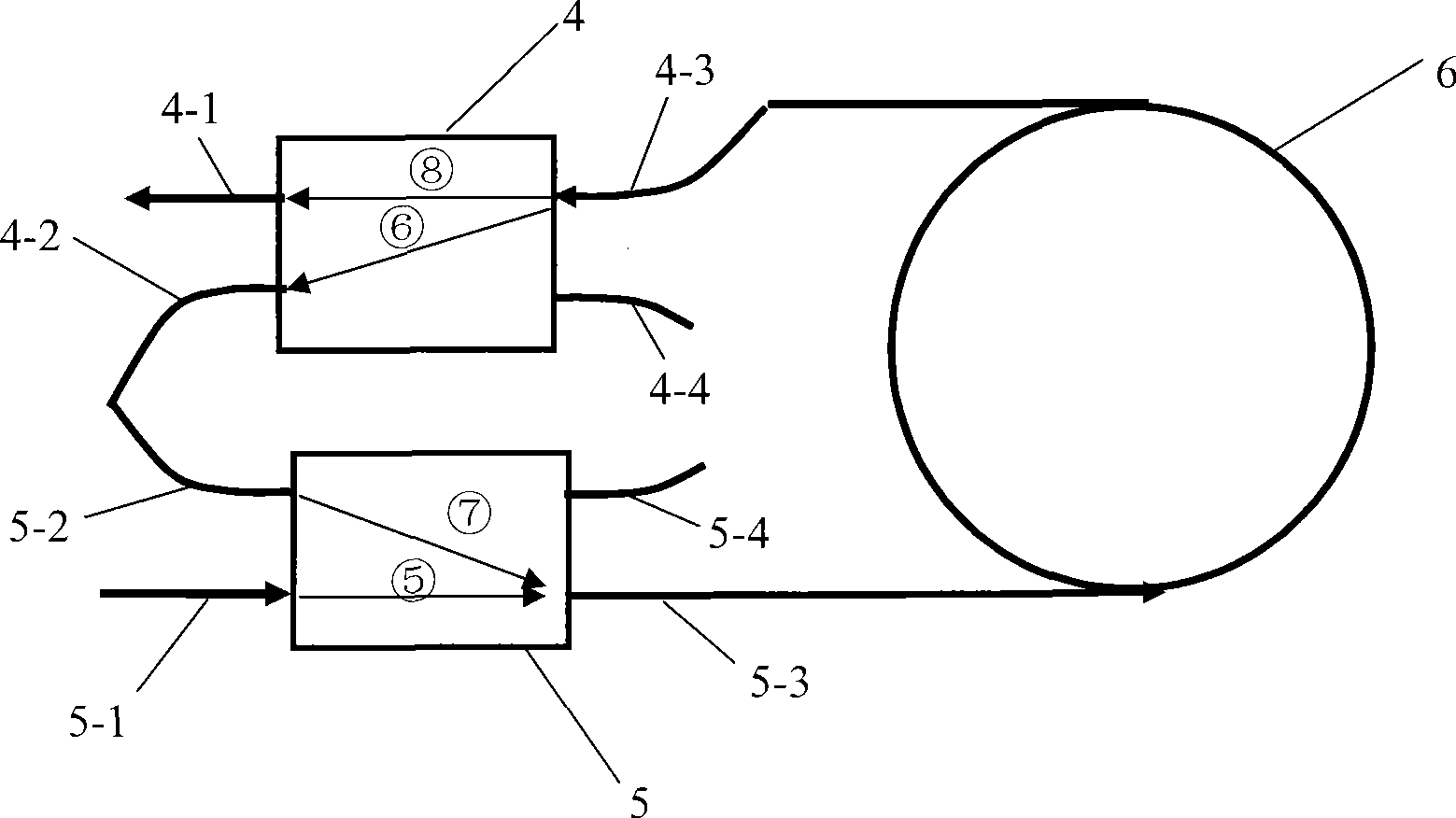

[0013] The wide-spectrum light source 1 is connected to the input port 2-1 at one end of the first coupler 2, the detector 7 is connected to the output port 2-2 at one end of the first coupler 2, and a port 2-3 at the other end of the first coupler 2 Connect to the single-ended port of Y-waveguide 3. One port in the double-ended port of the Y waveguide 3 is connected with a port 4-1 at one end of the second coupler 4, and another port in the double-ended port of the Y waveguide 3 is connected with a port 5-1 at one end of the third coupler 5. 1 connection, and another port 4-2 at one end of the second coupler 4 is connected with another port 5-2 at one end of the third coupler 5. A port 4-3 at the other end of the second coupler 4 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com