Device for protecting electrical equipment against overvoltages

A technology of overvoltage protection and electronic equipment, which is applied in the direction of emergency protection circuit devices, emergency protection circuit devices, circuit devices, etc. for limiting overcurrent/overvoltage, and can solve the problems of mechanical separation and loosening, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

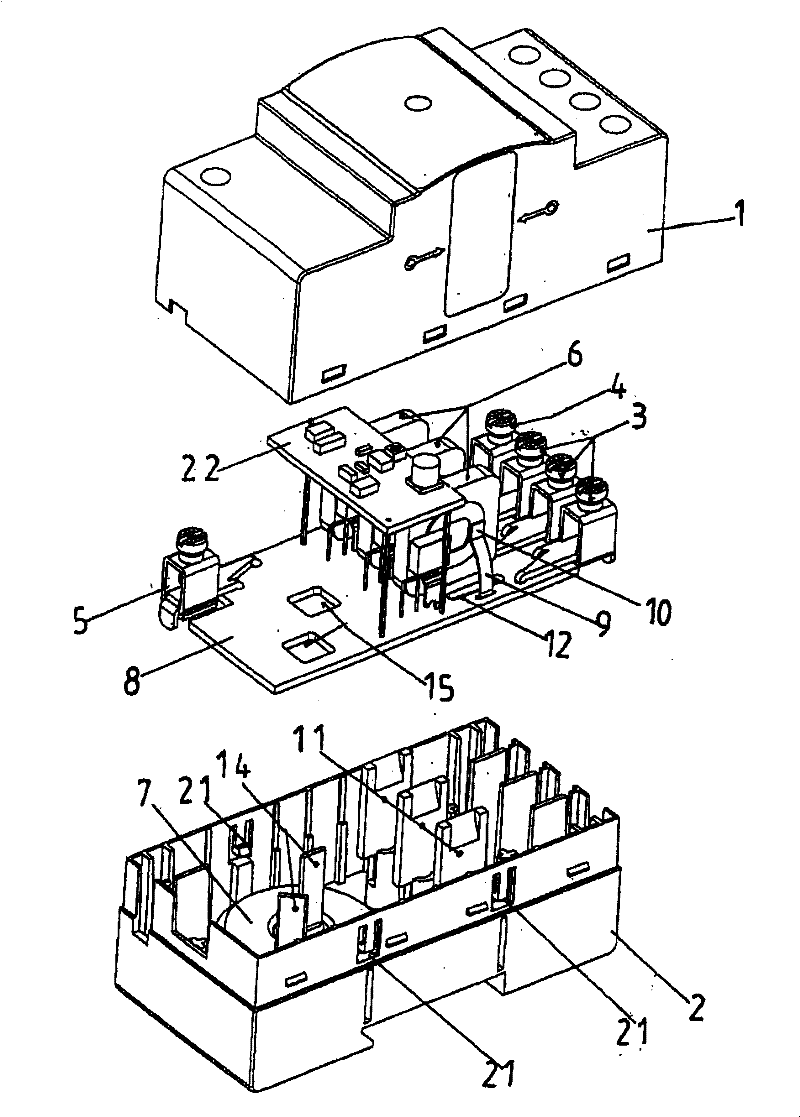

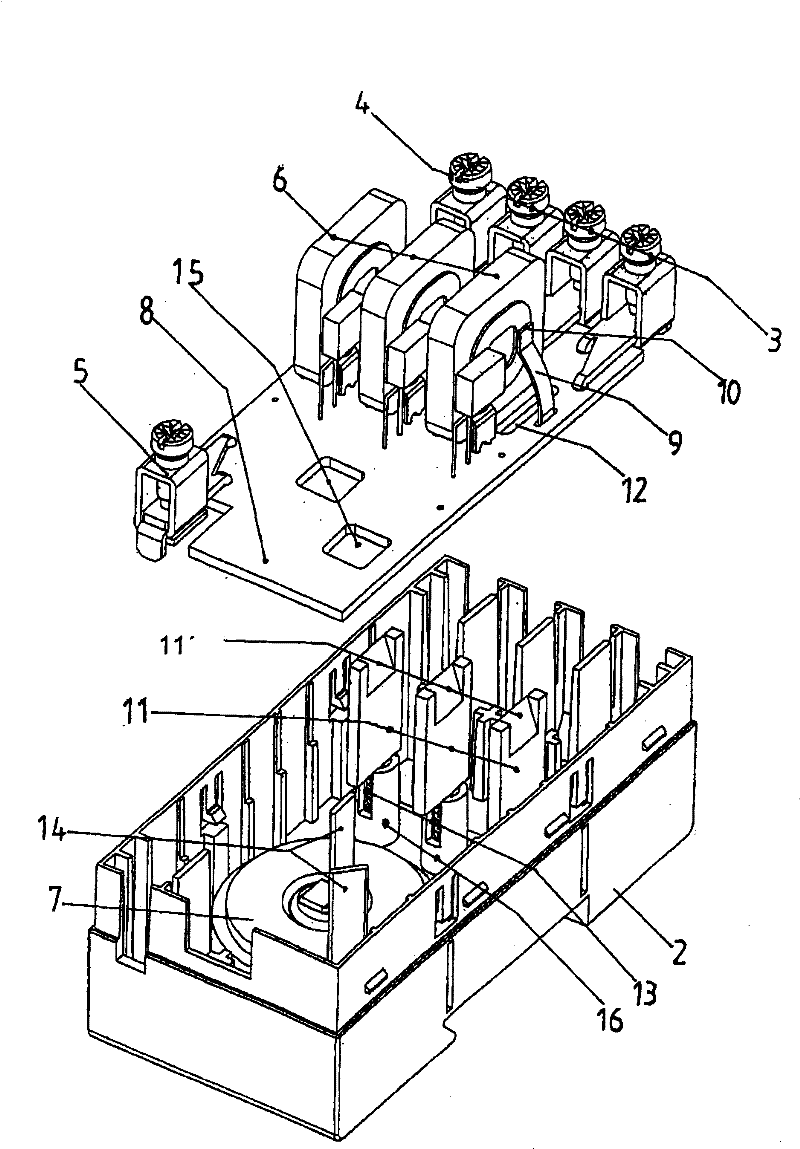

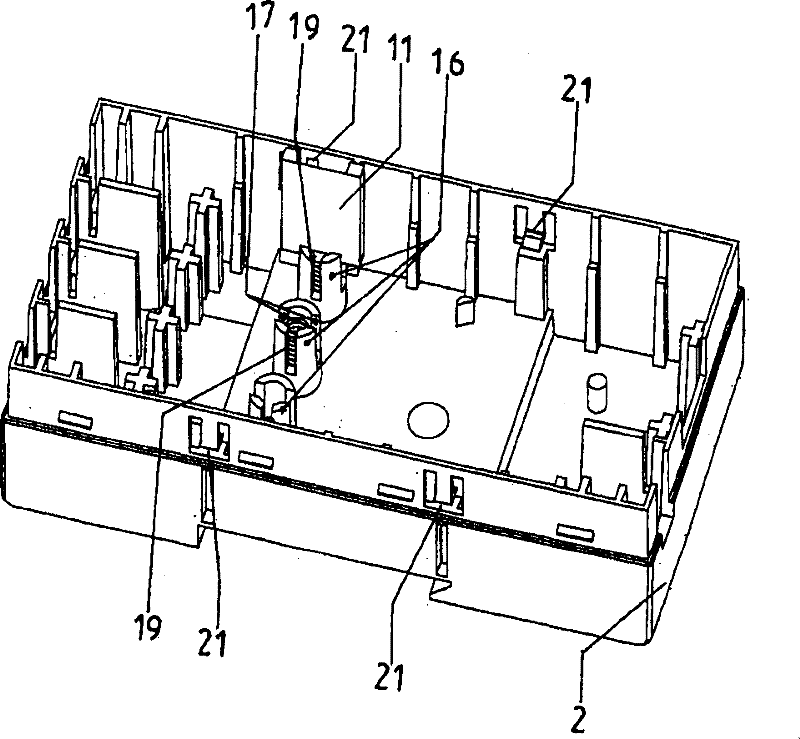

[0028] exist figure 1The components of the device for overvoltage protection are shown in . The device consists of an upper housing part 1 and a lower housing part 2 . The two housing parts are made of insulating material. The two housing parts can be assembled and snapped together in a corresponding manner. The overvoltage element, which will be described below, as well as the terminal 3 for the phase conductors L1 to L3 as well as the terminal 4 for the neutral conductor and the terminal 5 for the protective conductor are provided in the housing. The circuit is set up in such a way that variable resistors 6 are respectively connected between the phase and neutral conductors as overvoltage protection. Furthermore, a spark gap 7 is inserted between the neutral conductor and the protective conductor. For the specified configuration, a printed circuit board 8 equipped with a varistor 6 and terminals 3 , 4 , 5 is arranged in the housings 1 , 2 . Fusible links 9 are welded on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com