Method for leaching vanadium from vanadium-containing coal mine

A technology for coal mines and vanadium stone, which is applied in the field of hydrometallurgy extraction of rare high melting point metals, can solve the problems of low vanadium conversion leaching rate, low production efficiency, high vanadium leaching rate, etc., and achieves efficient direct leaching and reduced reaction time. , the effect of process strengthening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

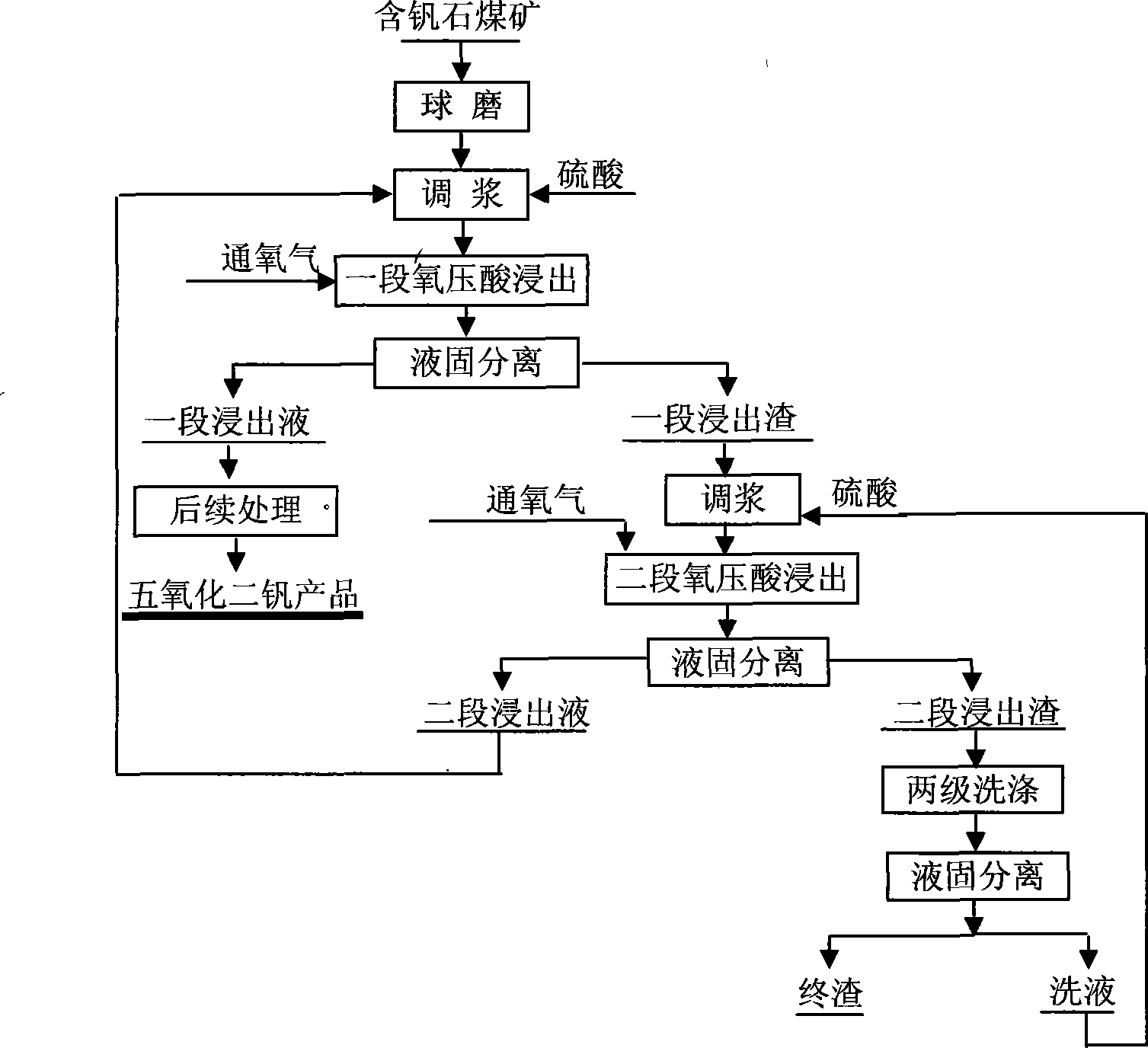

Image

Examples

Embodiment 1

[0022] Stone coal contains 1.84% vanadium, and the ore sample is ground to 200 mesh, accounting for 85%.

[0023] One-stage oxygen pressure acid leaching: the vanadium-containing stone coal mine is mixed with a sulfuric acid solution with a concentration of 200g / L, and the solid-liquid mass volume ratio is controlled to be 1:1.2. Pressure 1.2MPa, conversion temperature 150°C, leaching reaction for 180 minutes, solid-liquid separation to obtain a vanadium-containing leaching solution and a leaching residue. The first-stage vanadium-containing leaching solution is processed through recovery of residual acid-extraction-reverse extraction-oxidation vanadium precipitation-pyrolysis to obtain vanadium pentoxide product, and the first-stage leaching residue enters the second-stage oxygen pressure acid leaching process.

[0024] Two-stage oxygen pressure acid leaching: Slurry the first-stage leaching slag and sulfuric acid solution with a concentration of 300g / L, control the solid-liq...

Embodiment 2

[0027] Stone coal contains 0.507% vanadium, and the ore sample is ground to 200 mesh, accounting for 95%.

[0028] One-stage oxygen pressure acid leaching: the vanadium-containing stone coal mine is mixed with sulfuric acid solution with a concentration of 180g / L, and the solid-liquid mass volume ratio is controlled to be 1:1.5. Pressure 1.5MPa, conversion temperature 120°C, leaching reaction for 120 minutes, solid-liquid separation to obtain a vanadium-containing leaching solution and a leaching residue. The first-stage vanadium-containing leaching solution is processed through recovery of residual acid-extraction-reverse extraction-oxidation vanadium precipitation-pyrolysis to obtain vanadium pentoxide product, and the first-stage leaching residue enters the second-stage oxygen pressure acid leaching process.

[0029] Two-stage oxygen pressure acid leaching: Slurry the first-stage leaching slag and sulfuric acid solution with a concentration of 250g / L, and control the solid-...

Embodiment 3

[0032] Stone coal contains 1.07% vanadium, and the ore sample is ground to 200 mesh, accounting for 85%.

[0033] One-stage oxygen pressure acid leaching: the vanadium-containing stone coal mine is mixed with sulfuric acid solution with a concentration of 250g / L, and the solid-liquid mass volume ratio is controlled to be 1:3. Pressure 2.0MPa, conversion temperature 180°C, leaching reaction for 240 minutes, solid-liquid separation to obtain a vanadium-containing leaching solution and a leaching residue. The first-stage vanadium-containing leaching solution is processed through recovery of residual acid-extraction-reverse extraction-oxidation vanadium precipitation-pyrolysis to obtain vanadium pentoxide product, and the first-stage leaching residue enters the second-stage oxygen pressure acid leaching process.

[0034] Two-stage oxygen pressure acid leaching: Slurry the first-stage leaching slag and sulfuric acid solution with a concentration of 300g / L, control the solid-liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com