Cereal particle hardness measurement method and its hardness measurement instrument

A technology for grain granules and measurement methods, which is applied in individual granule analysis, testing material hardness, granule and sedimentation analysis, etc., and can solve the problems of cumbersome and time-consuming testing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

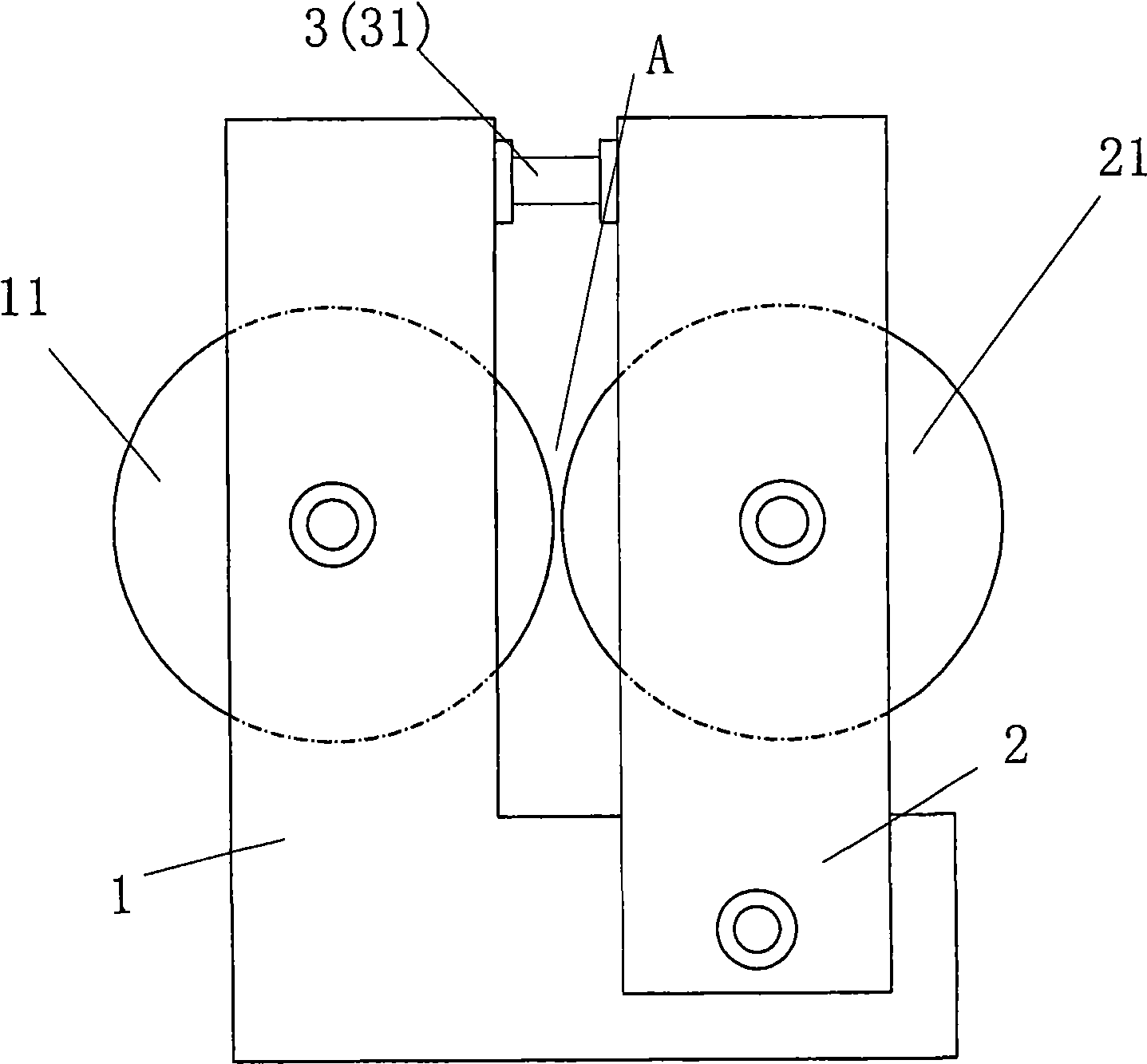

[0026] Such as figure 1 Shown, a kind of grain grain hardness tester, described grain grain hardness tester comprises a base 1, and described base 1 is provided with a first roll 11; A support seat 2 can be arranged on described base 1, the support base 2 is arranged on one side of the base 1, a second roll 21 is arranged on the support base 2 opposite to the first roll 11, and the two rolls 11, 21 rotate in opposite directions (the two rolls can be driven by a motor or Speed reducer or other transmission modes drive the rotation, which is the prior art and will not be repeated here), and there is a gap A between the two rolls 11, 21; a force sensor is arranged between the base 1 and the support seat 2 3. In this embodiment, the force sensor 3 is a tension sensor 31 , one end of the tension sensor 31 is connected to the base 1 , and the other end is connected to the support base 2 .

[0027] The method for measuring the hardness of grain grains of the present invention is...

Embodiment approach 2

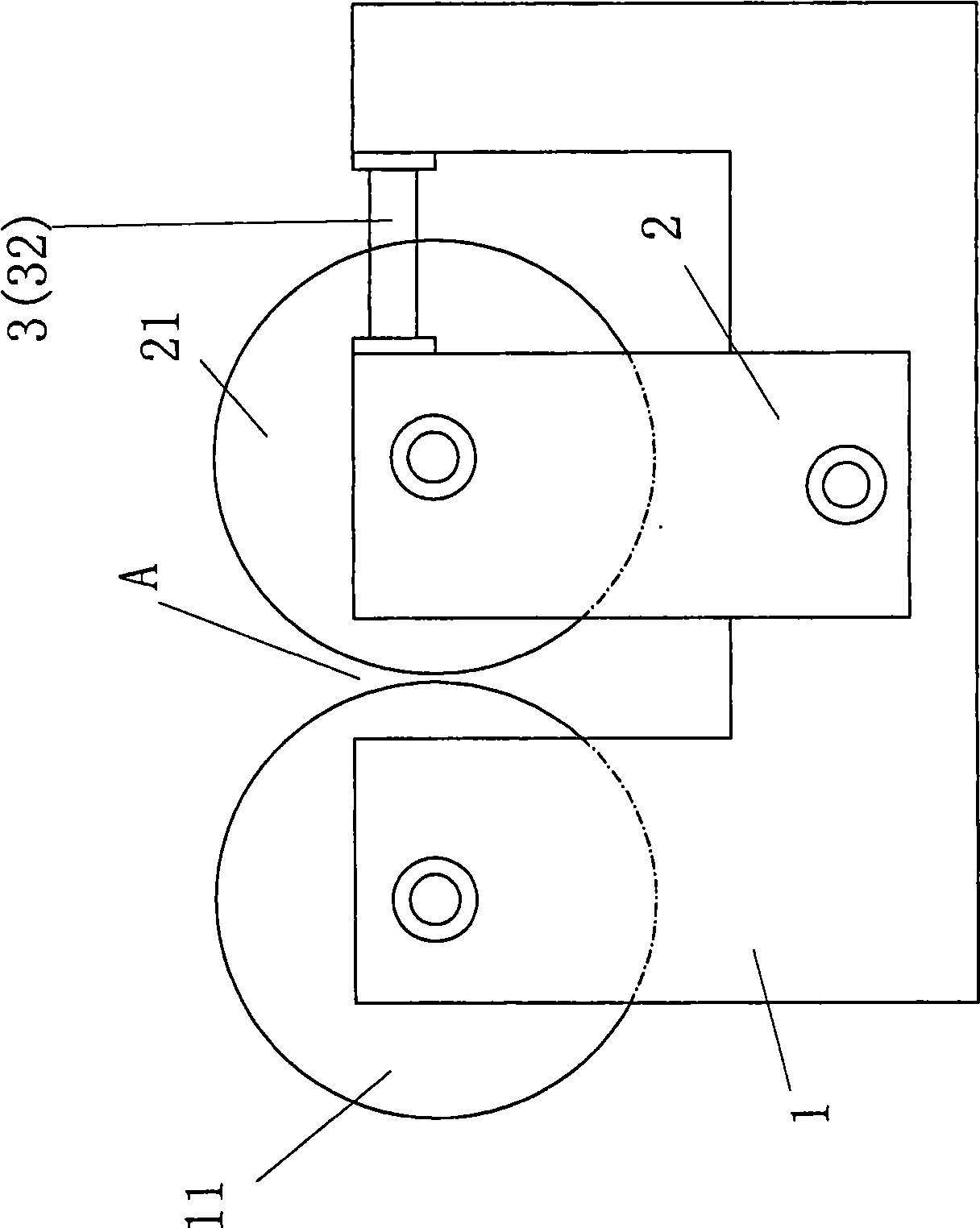

[0033] The principle and structure of this embodiment are basically the same as those of Embodiment 1, the difference is that figure 2 As shown, the force sensor 3 is a pressure sensor 32 .

[0034] When the cereal grain hardness tester of the present invention is in use, multiple single grain grains enter the gap A between the first roll 11 and the second roll 21 in turn, and the grain grains pass through under the drive of the two oppositely rotating rolls 11 and 21. The gap A is crushed under the pressure of the two rolls 11, 21, and the grain grains are broken while producing a reaction force to the two rolls 11, 21. Under the action of the reaction force, the support base 2 produces a slight displacement relative to the base 1. At this time, the slight swing of the support base 2 generates pressure on the pressure sensor 32; the pressure sensor 32 transmits the pressure data to the data acquisition process system, the data acquisition and processing system calculates an...

Embodiment approach 3

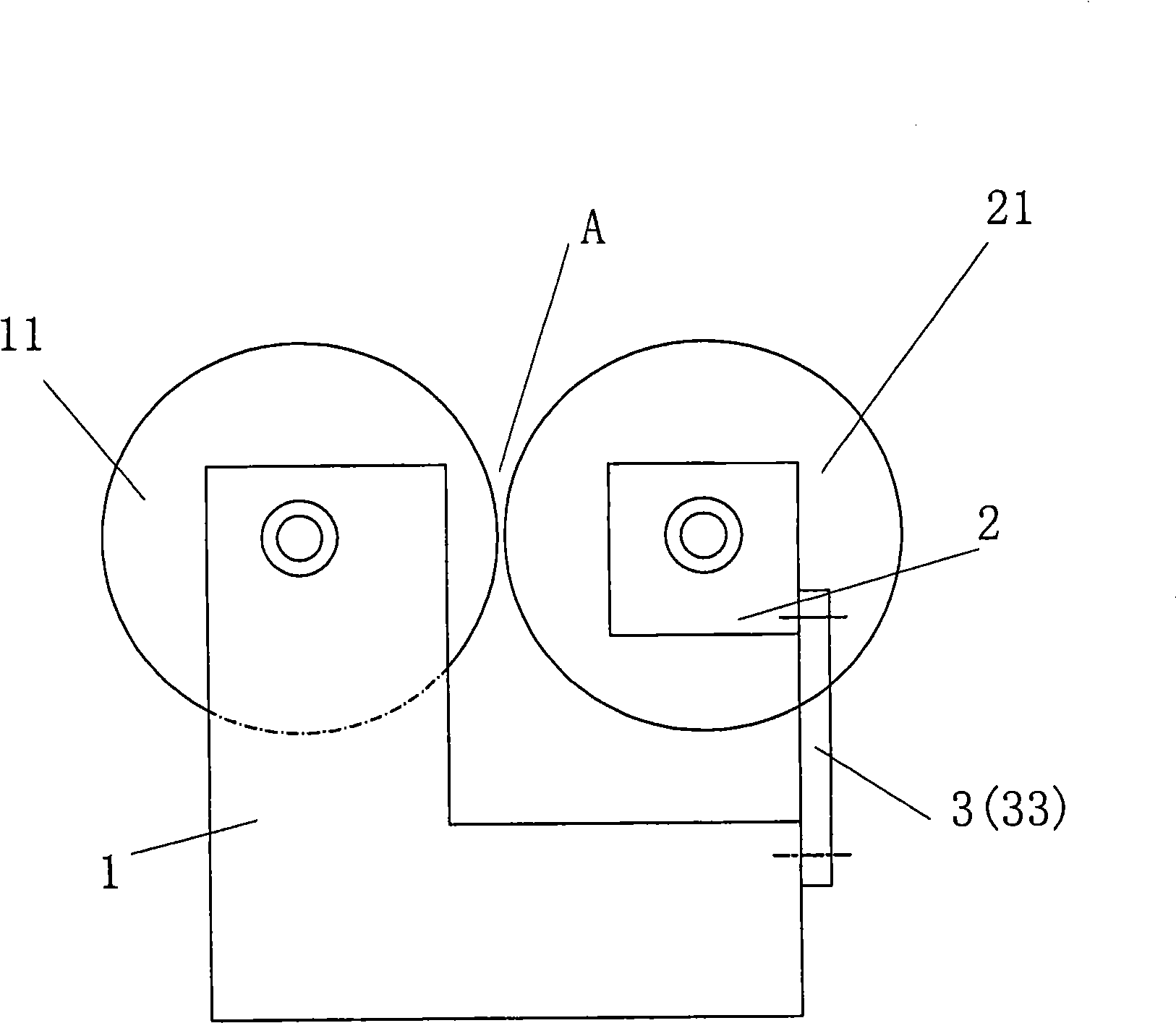

[0037] The principle and structure of this embodiment are basically the same as those of Embodiment 1, the difference is that image 3 As shown, the support base 2 is fixed on the base 1 through a cantilever load cell 33; in this structure, the cantilever load cell 33 is connected with the base 1 and the support base 2 as a whole, and the support base 2 will be delivered to the cantilever load cell 33, and the second roller 21 can be reset by the elastic action of the cantilever load cell 33 itself.

[0038]When the cereal grain hardness tester of the present invention is in use, multiple single grain grains enter the gap A between the first roll 11 and the second roll 21 in turn, and the grain grains pass through under the drive of the two oppositely rotating rolls 11 and 21. The gap A is crushed under the pressure of the two rolls 11, 21, and the grain grains are broken while producing a reaction force to the two rolls 11, 21. Under the action of the reaction force, the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com