Great-wall shaped oil collection net of oil-smoke sucker

A technology of range hood and Great Wall, which is applied in the field of oil collection nets, and can solve the problems of oil dripping from oil collection nets and contamination of dishes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

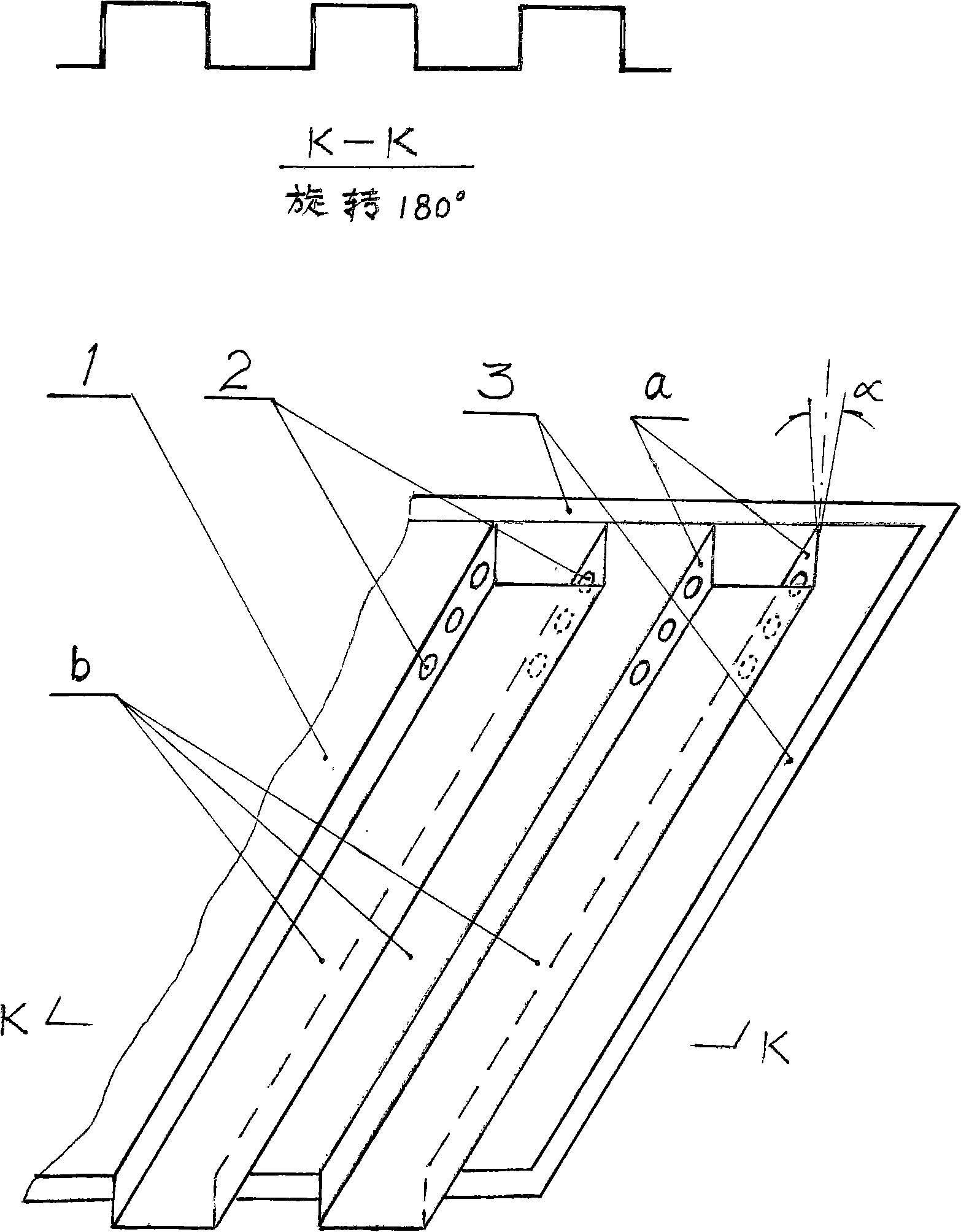

[0009] Attached below figure 1 The specific implementation of the present invention is described further:

[0010] The following two methods can be adopted to realize the Great Wall-shaped oil collecting net of the range hood of the present invention:

[0011] (1) sheet metal is the method for stamping with material: at first according to the shape of range hood Great Wall shape oil collecting net of the present invention calculates the size of sheet metal, then process respectively the through hole 2 (through hole) on the side on the lathe 2 can be various shapes). Finally, on the machine tool, the Great Wall-shaped oil collecting net of the range hood of the present invention is pressed with a Great Wall-shaped concave-convex die.

[0012] (2) metal or non-metallic material pouring method: at first according to the shape of the range hood Great Wall shape oil collection net of the present invention, two pouring molds with through holes 2 are respectively prepared, then the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com