Method for improving thermal stability of acetic ester starch slurry viscosity

A technology of starch acetate and sizing viscosity, used in textiles, papermaking, fiber processing, etc., can solve the problems of poor thermal stability of starch acetate sizing viscosity, improve textile production efficiency, product quality, and stable sizing quality. , Overcome the effect of poor thermal stability of viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

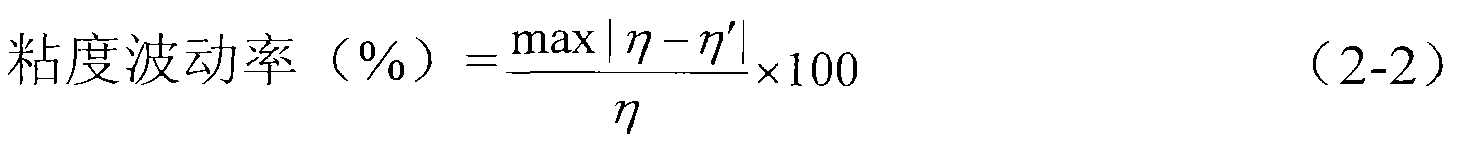

Image

Examples

Embodiment Construction

[0020] The invention will be further described in conjunction with examples.

[0021] The method for improving the viscosity heat stability of acetate starch slurry comprises carrying out oxidative denaturation, esterification denaturation and cross-link denaturation to tapioca starch, comprises the following steps:

[0022] ①. Oxidative denaturation: 200 parts by weight of cassava starch are dispersed in 300 parts of distilled water to prepare a starch suspension emulsion with a concentration of 40%. After stirring evenly, move it into a 1000ml three-necked flask, and use a concentration of 3% hydrogen Sodium oxide solution adjusts the pH value of cassava starch slurry to 8.0-8.2, adds sodium hypochlorite solution, the addition is 5% of the weight of cassava starch, oxidizes at room temperature for 3 hours, and dechlorinates;

[0023] 2. Esterification denaturation: be 3% sodium hydroxide solution with concentration to adjust cassava starch slurry pH value to be 9.0~9.2, add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com