Support roller for drying grate

A technology for grate machines and rollers, which is applied in the direction of rollers, conveyors, conveyor objects, etc., can solve the problems of increased wear and energy consumption, and achieve the goals of reducing driving energy consumption, reducing driving energy consumption, and reducing wear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] It should be noted that the idler rollers of the grate machine have various forms. In terms of the number of sprockets and smooth rollers alone, there is a big difference. For example, for a grate bed with 6 rows of chains, the sum of smooth rollers and sprockets on the rollers is 6; for a grate bed with 7 rows of chains, the sum of smooth rollers and sprockets on the rollers is 7, etc. In this embodiment, only the idler roller with four smooth idlers and sprockets on the idler roller will be described.

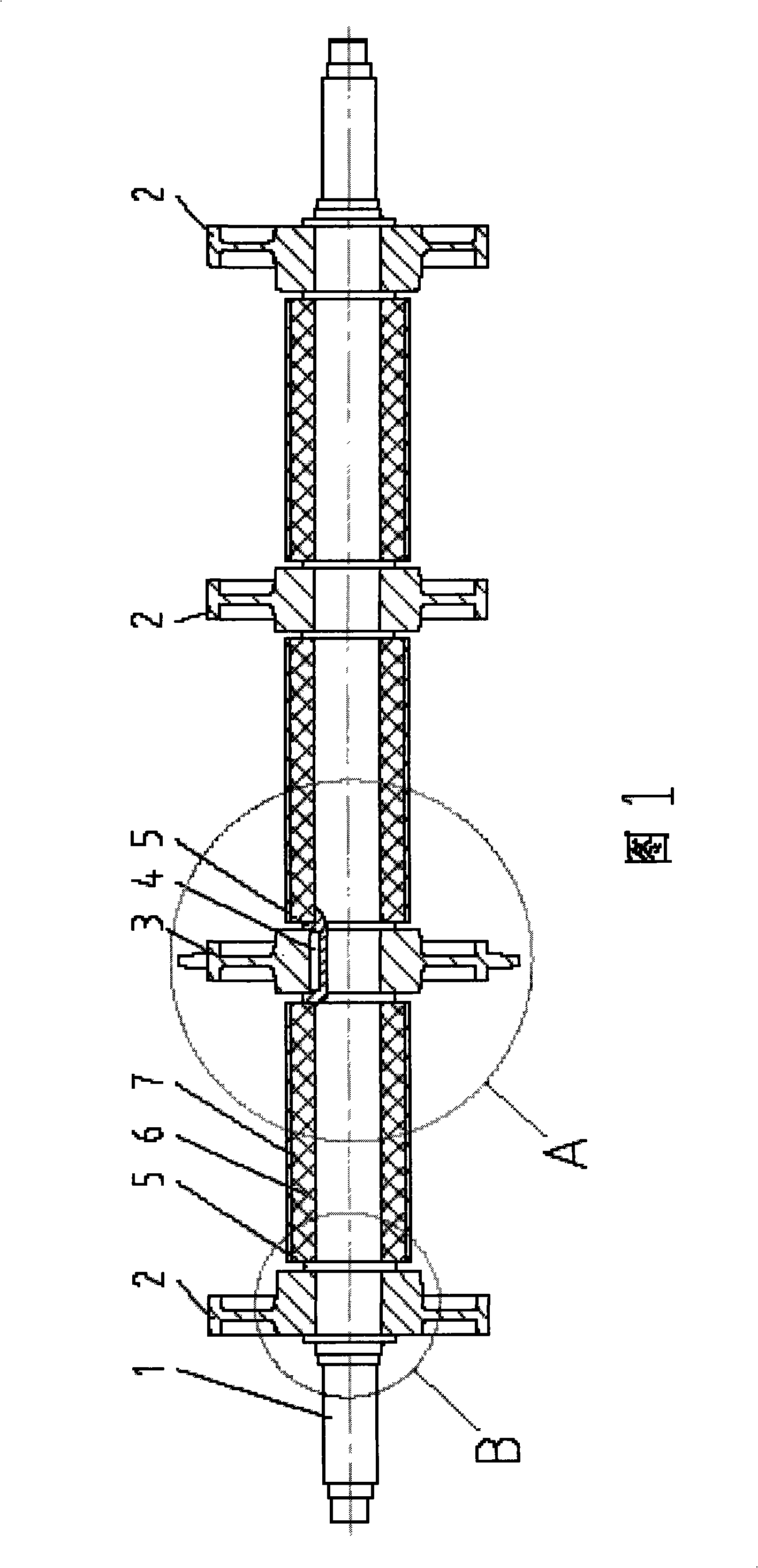

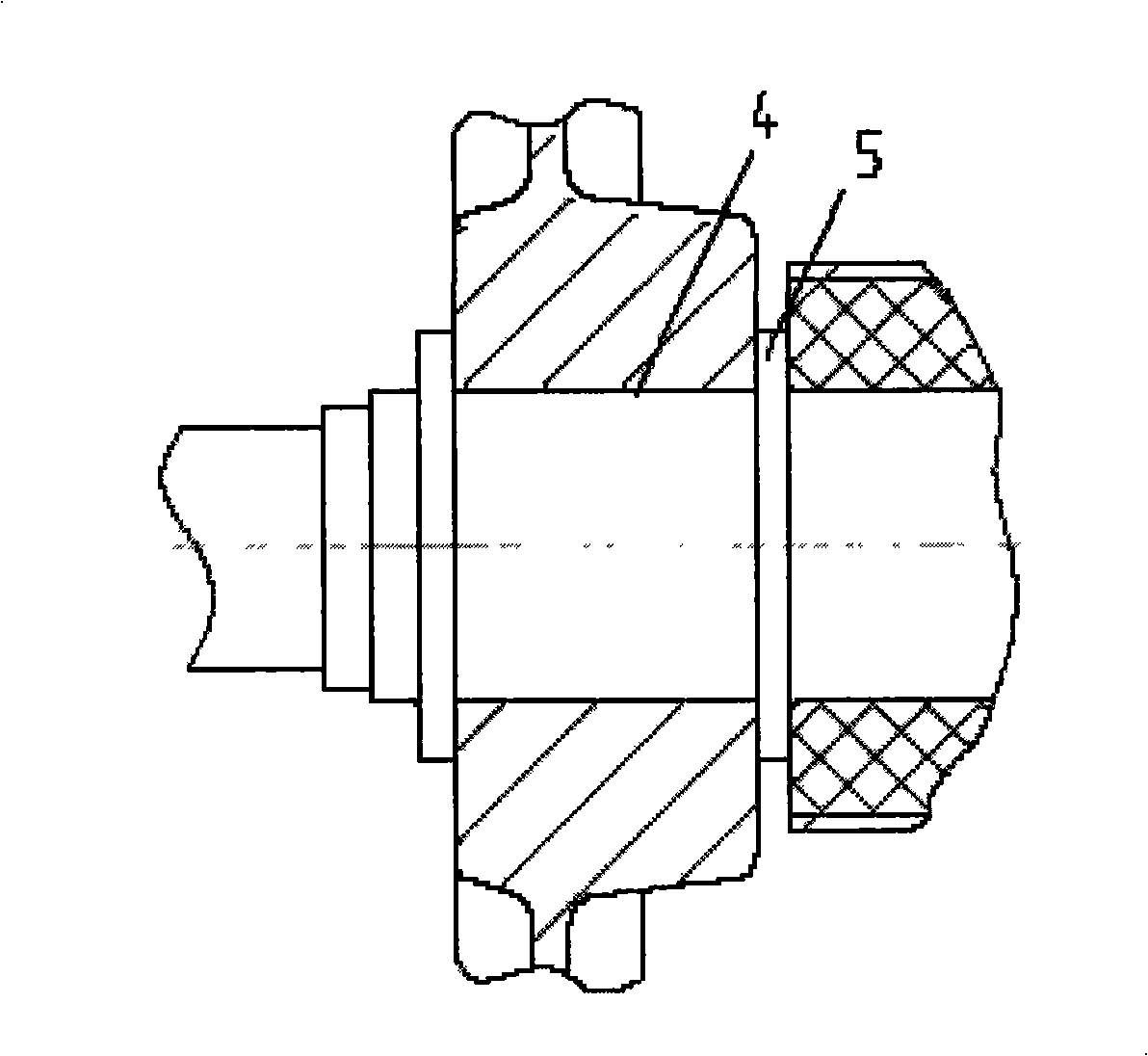

[0022] In the structural diagram of Example 1 shown in Figure 1, 1 is the idler shaft; 2 is the smooth idler, and there are three on each idler, all of which are split, and the smooth idler 2 is empty on the idler shaft 1 forms a clearance fit; 3 is a sprocket, one of which is split, and the sprocket 3 is connected with the idler shaft 1 through a flat key 4, and its axial direction is limited by the shoulder 5 on the idler shaft 1 Move to meet the needs of the grate...

Embodiment 2

[0024] In this embodiment, only the idler roller whose sum of smooth idlers and sprockets is 6 on the idler roller is described.

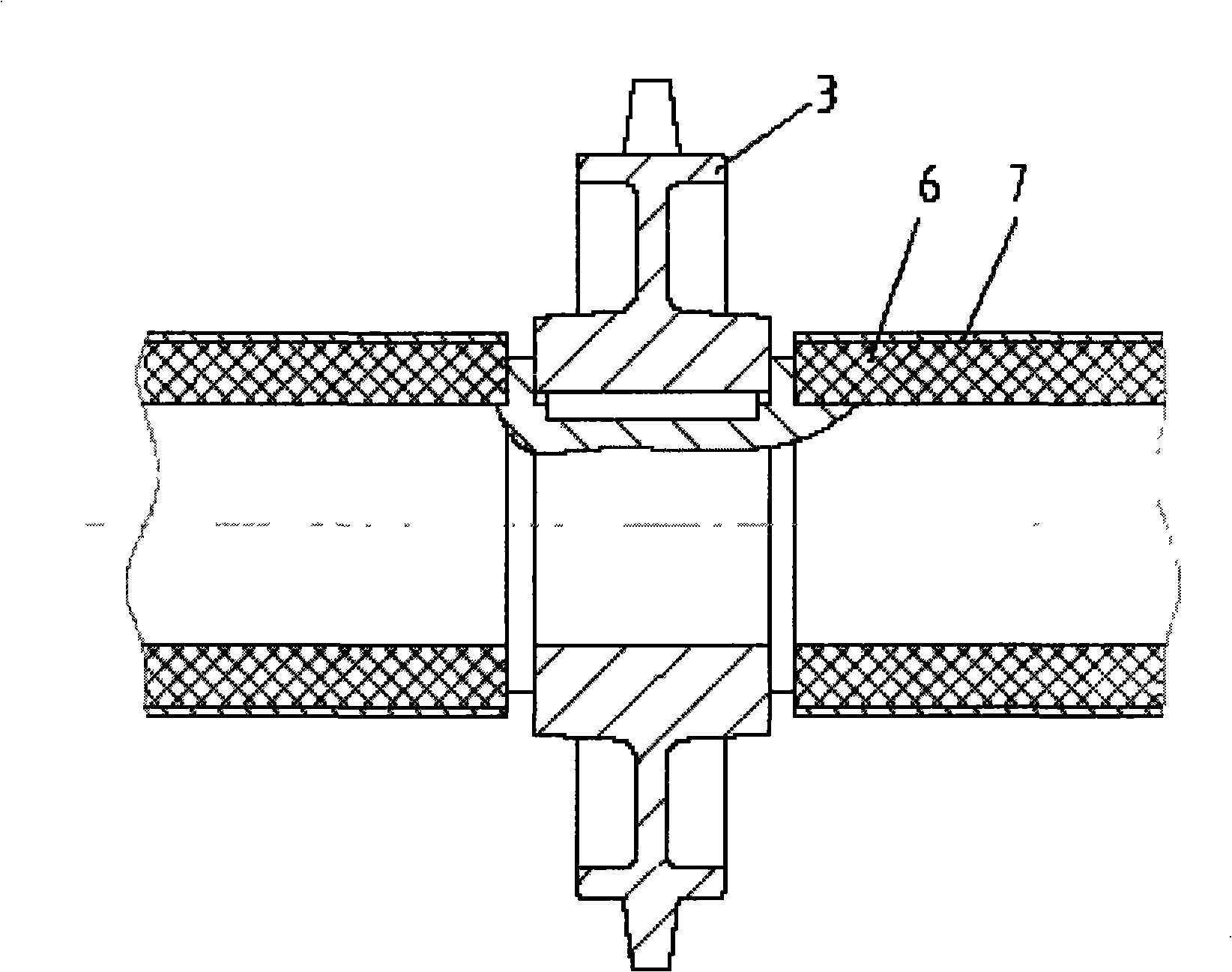

[0025] In the schematic structural diagram of embodiment 2 shown in Figure 4, 1 is the idler shaft; 2 is the smooth idler, and there are four on each idler, all of which are split, and the smooth idler 2 is installed through the sliding bearing 8 On the idler shaft 1, the sliding bearing 8 is a gray cast iron sliding bearing, and the half-bearing bush of the sliding bearing 8 is inlaid on the smooth supporting roller 2, which can be replaced together with the smooth supporting roller 2; 3 is a sprocket, and there are 2, for Split type, the sprocket 3 is connected with the idler shaft 1 through the flat key 4 and its axial movement is restricted by the shoulder 5 on the idler shaft 1, so as to meet the need for guiding the grate bed; 6 is heat insulation material , the effect is to reduce the heat of the idler shaft 1, and 7 is a heat insulation sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com