Light mineral wool slab

A mineral wool board, lightweight technology, applied in the field of mineral wool board to achieve the effect of improving performance and reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] First, weigh each material according to 5% of perlite, 70% of rock wool, 5% of flocculant, 5% of starch, 5% of paper, 1% of wet strength agent, 1% of sizing agent, and 8% of aluminum sulfate. Among them, The percentages of each component are percentages by weight, and the flocculant, wet strength agent and sizing agent are conventional flocculants, wet strength agents and sizing agents respectively.

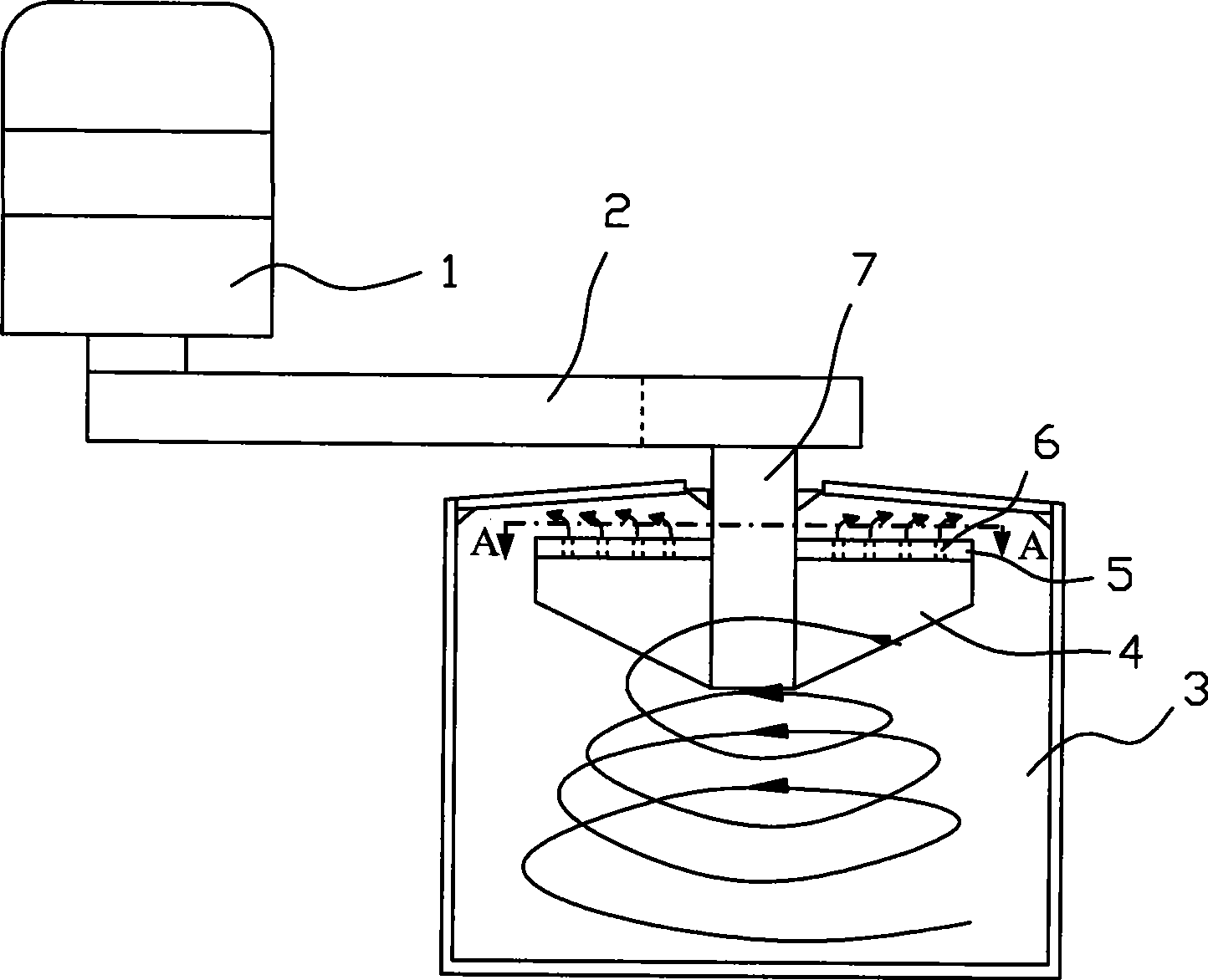

[0012] Second, follow the figure 1 As shown, in a mixing tank 3, 20% of the total weight of appropriate water, perlite, sizing agent and the above-mentioned granular cotton will be added successively to the mixing tank 3 for premixing, and when mixing The liquid generates shear force in the mixing tank 3, and the perlite is fully dispersed in the mixed liquid through the shear force.

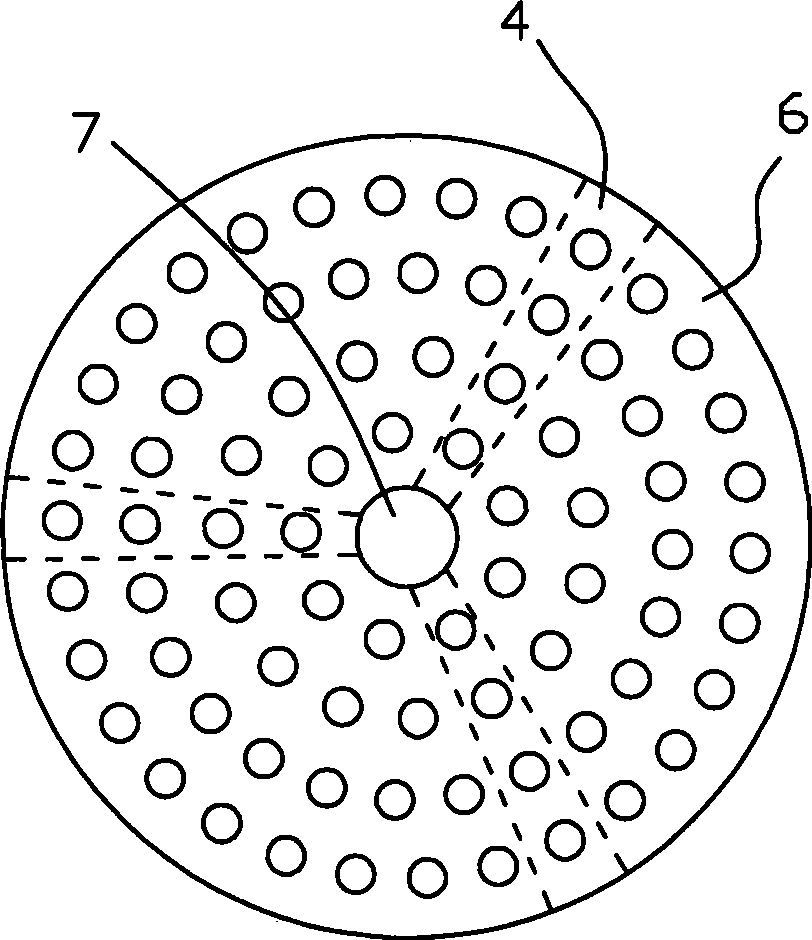

[0013] This shear force can be generated by, for example, figure 1 , 2 The rotary mixing mechanism shown is realized, specifically: the rotary mixing mechanism includes a drive motor 1, a...

Embodiment 2

[0019] First, weigh each material according to 30% of perlite, 30% of rock wool, 15% of flocculant, 10% of starch, 10% of paper, 0.2% of wet strength agent, 0.2% of sizing agent, and 4.6% of aluminum sulfate. Among them, The percentages of each component are percentages by weight.

[0020] The specific preparation process is the same as in Example 1, and the weight of the obtained lightweight mineral wool board is only 70% of that of the mineral wool board without adding perlite, and the sound absorption coefficient (NRC) is greater than or equal to 0.55, which is more sound-absorbing than ordinary pure cotton boards. The performance has been greatly improved (generally NRC is around 0.4).

Embodiment 3

[0022] First, weigh each material according to 15% of perlite, 45% of rock wool, 10% of flocculant, 7% of starch, 15% of paper, 0.5% of wet strength agent, 0.5% of sizing agent, and 7% of aluminum sulfate. Among them, The percentages of each component are percentages by weight.

[0023] The specific preparation process is the same as in Example 1. The weight of the obtained lightweight mineral wool board is only 25% of that of the mineral wool board without adding perlite, and the sound absorption coefficient (NRC) is greater than or equal to 0.55, which is more sound-absorbing than ordinary pure cotton boards. The performance has been greatly improved (generally NRC is around 0.4).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| sound absorption coefficient | aaaaa | aaaaa |

| sound absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com