Vertical rolling washing machine and control method thereof

A washing machine and rolling washing technology, which is applied to other washing machines, washing machines with containers, washing devices, etc., can solve the problems of limited friction and low washing degree of clothes, and achieve reduced water consumption, free washing methods, and high washing degree Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

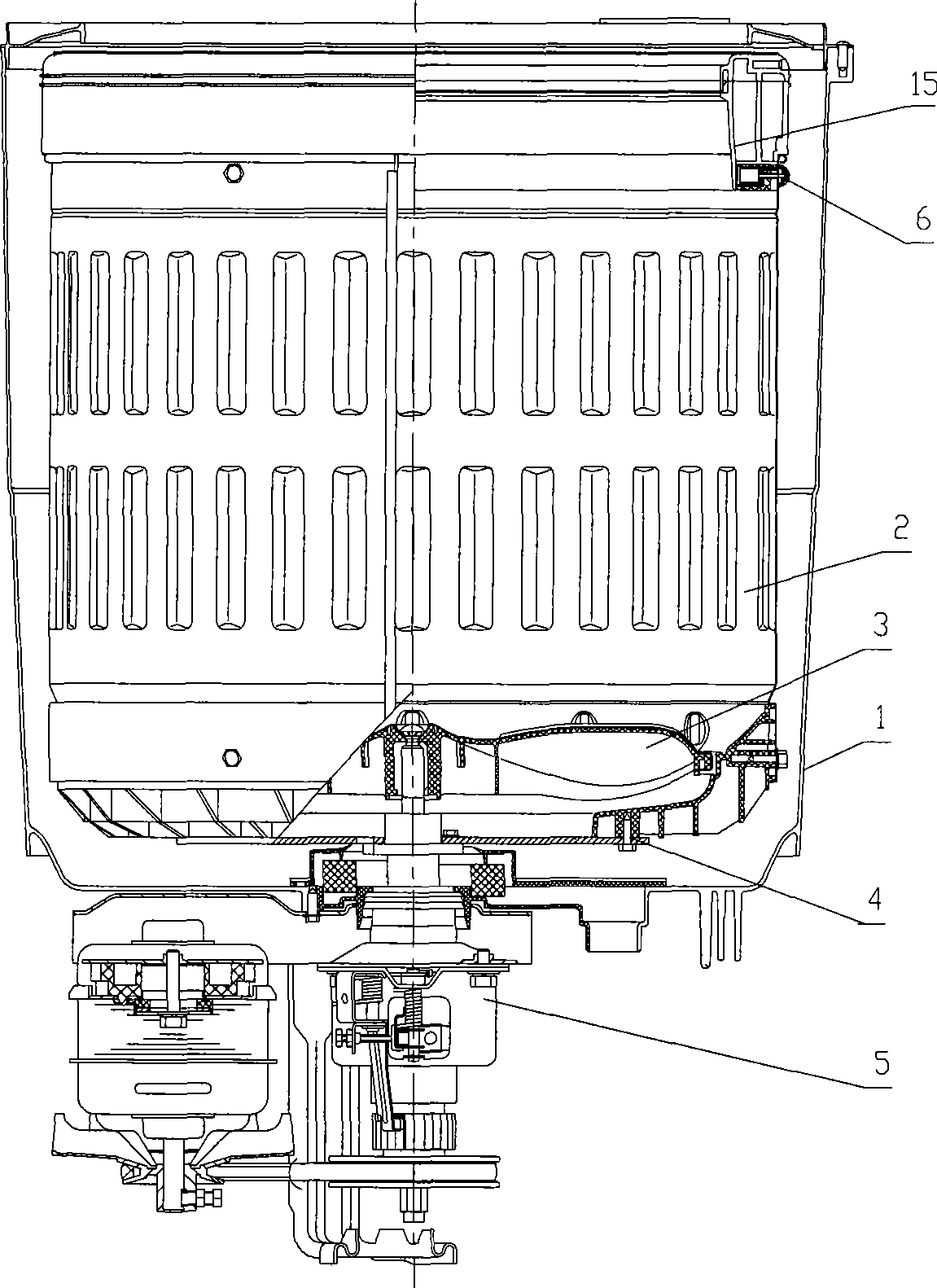

[0054] Example 1, such as Figure 1 to Figure 5 As shown, the vertical rolling washing machine described in this embodiment has a box body, and an outer tub 1 , a washing inner tub 2 , a chassis assembly 4 and a driving mechanism 5 are arranged inside the box body.

[0055] The outer tub 1 is connected with the box body through a suspender, and the chassis assembly 4 is connected with the washing inner tub 2 .

[0056] A washing inner tub 2 is arranged inside the outer tub 1 , the chassis assembly 4 is at least connected to the washing inner tub 2 , and a balancing ring 15 is arranged at the opening of the washing inner tub 2 top.

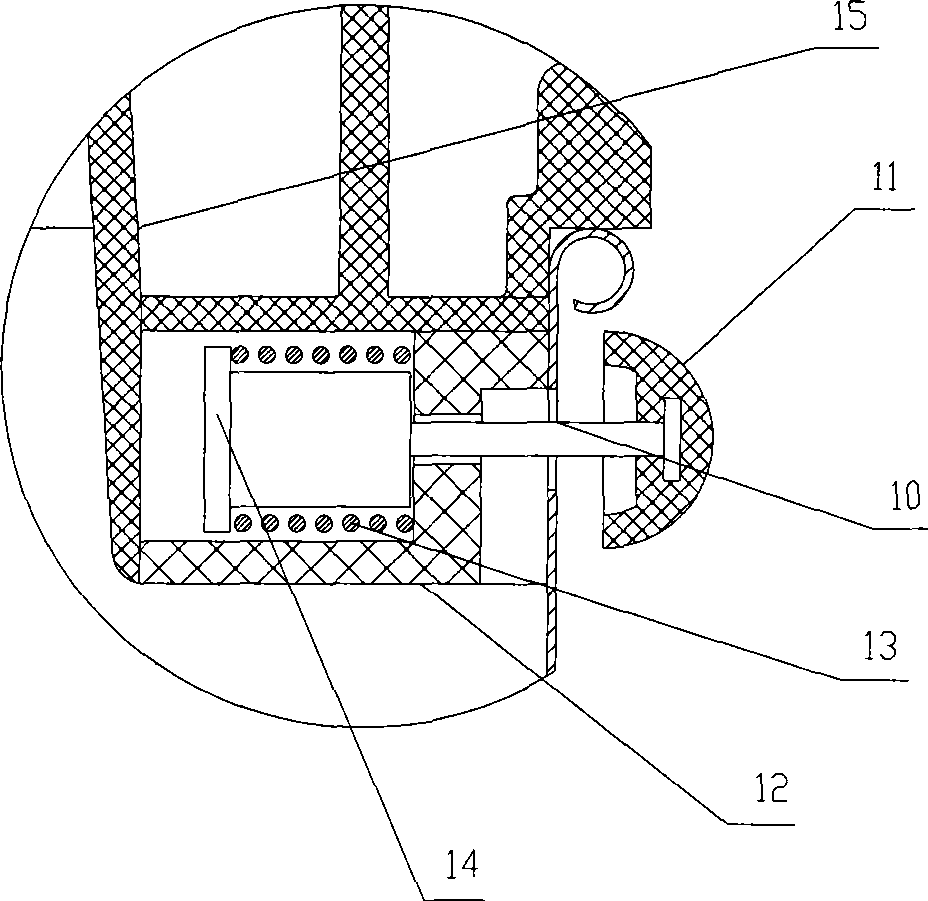

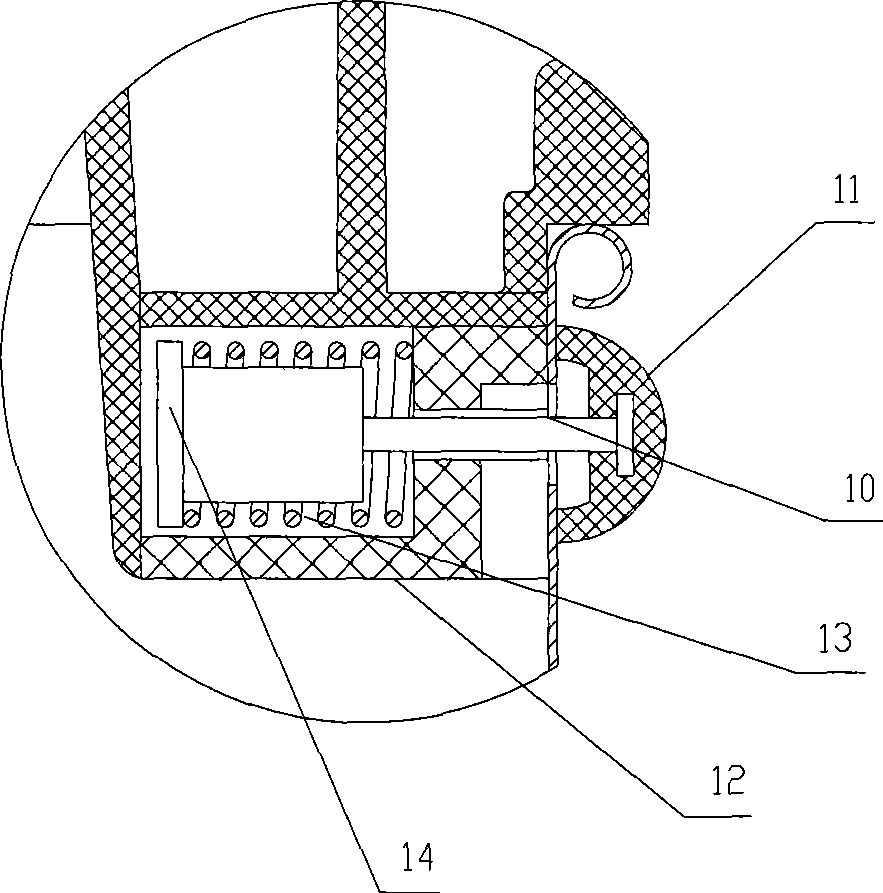

[0057] For washing the inner tub 2, several dehydration drainage holes 10 evenly distributed in the horizontal circumferential direction are provided only under the balance ring on the top of the tub wall, and a centrifugal drainage valve 6 is arranged at each dehydration drainage hole 10 so as to control the dehydration drainage holes 10. It is o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com