Dressing agent and preparation thereof

A technology of color repairing agent and solvent, which is applied in the field of color repairing agent for dyeing defects and its preparation, which can solve the problems of high price and achieve the effect of avoiding color difference and strong diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

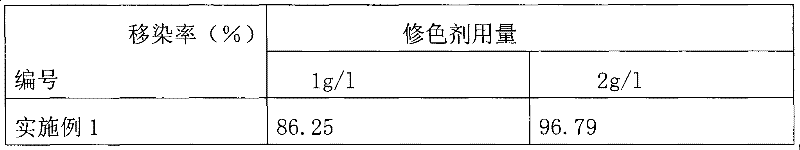

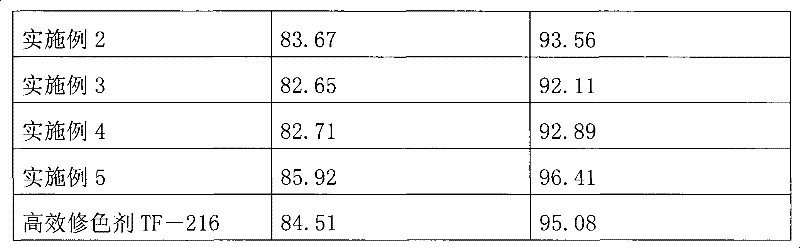

Examples

Embodiment 1

[0016] Add 100 grams of propylene glycol methyl ether, 250 grams of N-isopropyl phthalimide, 50 grams of isomeric tridecanol polyoxyethylene ether 1308, and 50 grams of aliphatic amine polyoxyethylene ether 1815 into a 1000ml three-necked flask. , 50 grams of ethanol, heat preservation between 40-45 ℃, stirring for 60 minutes, discharging.

Embodiment 2

[0018] Add 200 grams of propylene glycol phenyl ether, 50 grams of N-n-butyl phthalimide, 100 grams of castor oil polyoxyethylene ether EL-20, 50 grams of Tween-80, 100 grams of isopropanol in a 1000ml three-necked flask, Keep warm at 40-45°C, stir for 90 minutes, and discharge.

Embodiment 3

[0020] Add 100 grams of cyclohexanol methyl ether, 200 grams of propylene glycol phenyl ether, 100 grams of Nongru No. 600, 50 grams of ethylene glycol monobutyl ether, and 50 grams of isopropanol into a 1000ml three-necked flask, and keep warm at 45-50°C , stirred for 70 minutes, and discharged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com