Support and its quick-dismantling structure

A technology of support frame and frame body, which is applied in the directions of support structure installation, machine table/bracket, support machine, etc., can solve the problems of increasing cost, manufacturing difficulty, missing threaded connectors, and lengthy process steps, and shortening disassembly and assembly. The effect of time, shortening of man-hours, and omitting disassembly and assembly steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

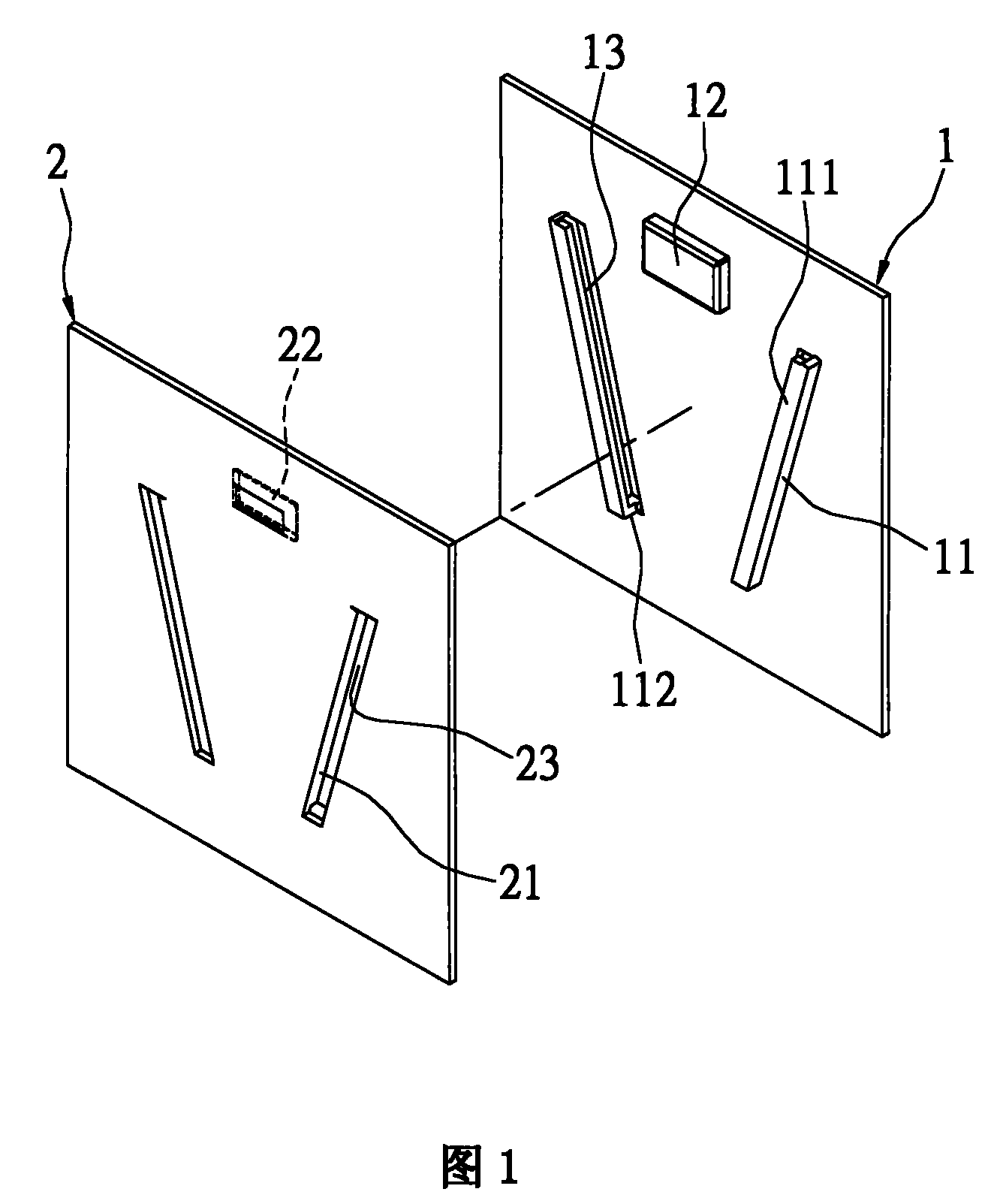

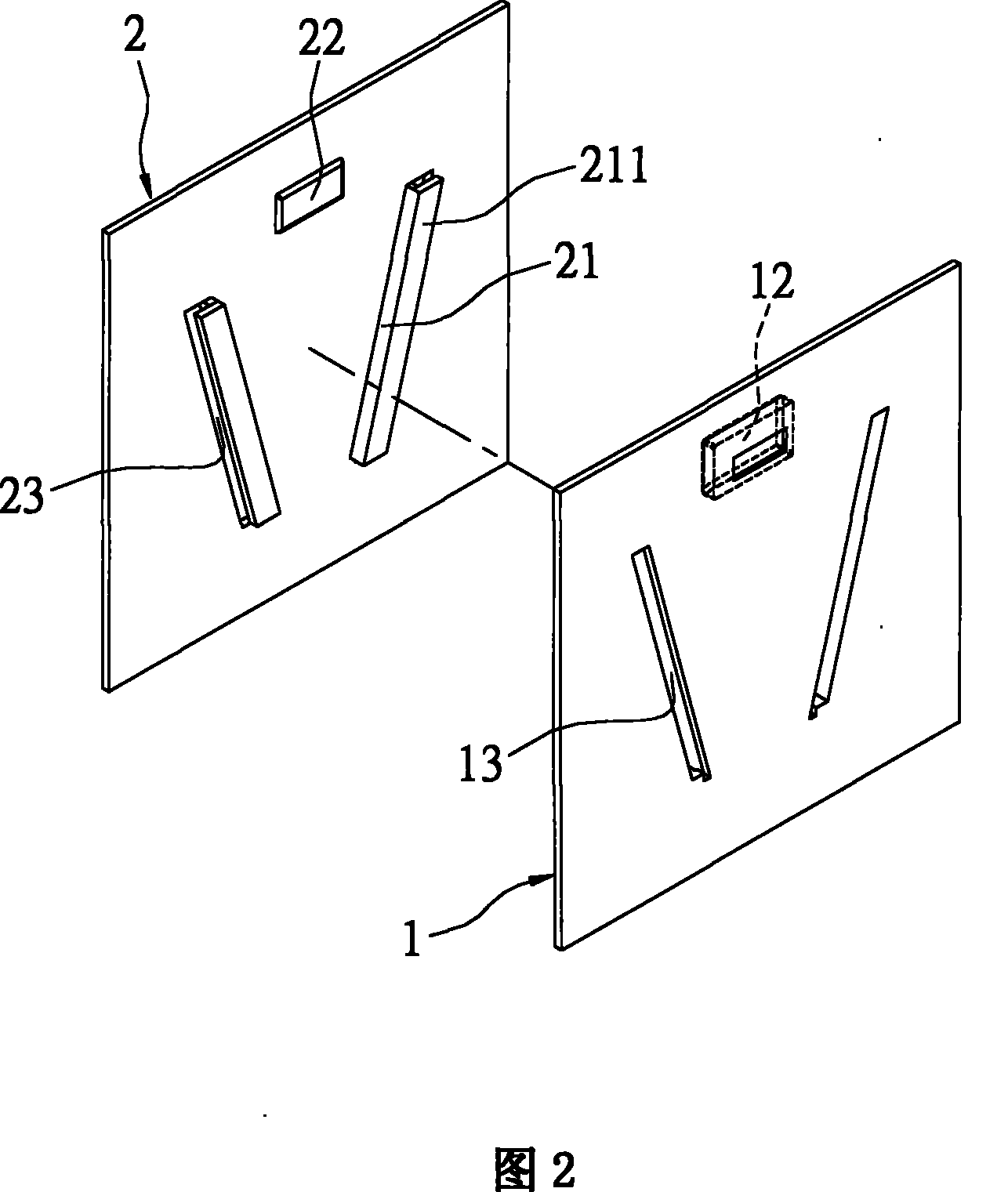

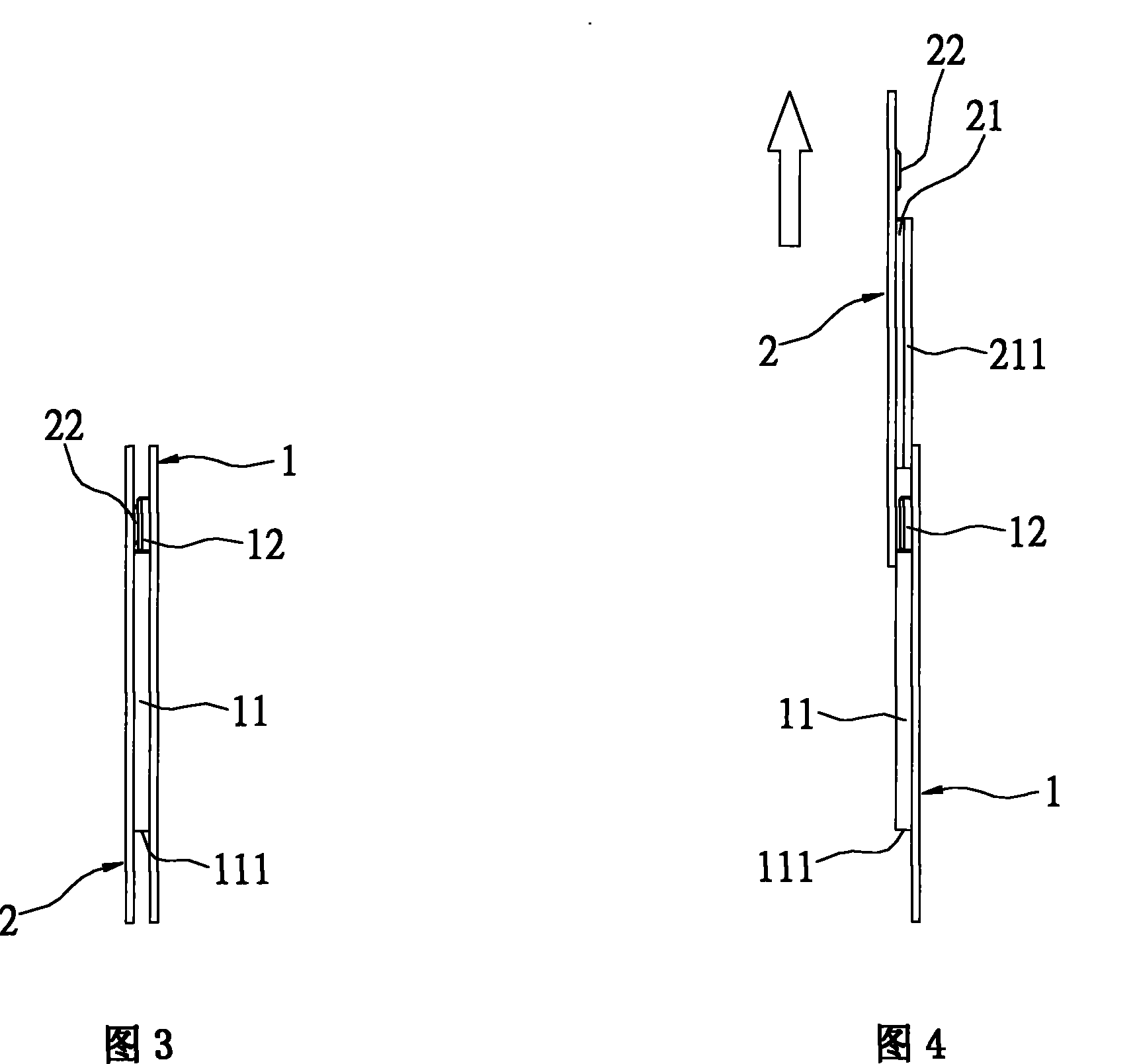

[0040] see Figure 1 to Figure 6 As shown, the support frame and its quick-release structure of the present invention are shown. The quick-release structure of the support frame includes: a bearing seat 1 and a mounting seat 2 .

[0041] see figure 1 and figure 2 As shown, the bearing base 1 is roughly in the shape of a square thick plate, and the bearing base 1 has two receiving plate parts 11 , an elastic stopper 12 and two hollow parts 13 .

[0042] The two receiving boards 11 are formed on one end surface of the bearing seat 1 and are arranged obliquely opposite to each other in a "eight" shape. Each of the two receiving plates 11 has a first extension portion 111 and a stop portion 112, the first extension portion 111 is formed by extending and turning the edge end of the receiving plate 11, and the stop portion 112 is formed on the The lower end edge of the receiving board 11 .

[0043] The elastic stopper 12 is a rubber, and the elastic stopper 12 is fixed between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com