Combinded processing lathe and its tool post

一种复合加工、刀架的技术,应用在车床、六角车床、金属加工等方向,能够解决限制很多、限制、不能充分缩短加工每个工件所需的时间等问题,达到减少加工自由度、缩短时间的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Hereinafter, preferred embodiments of the present invention will be described with reference to the drawings.

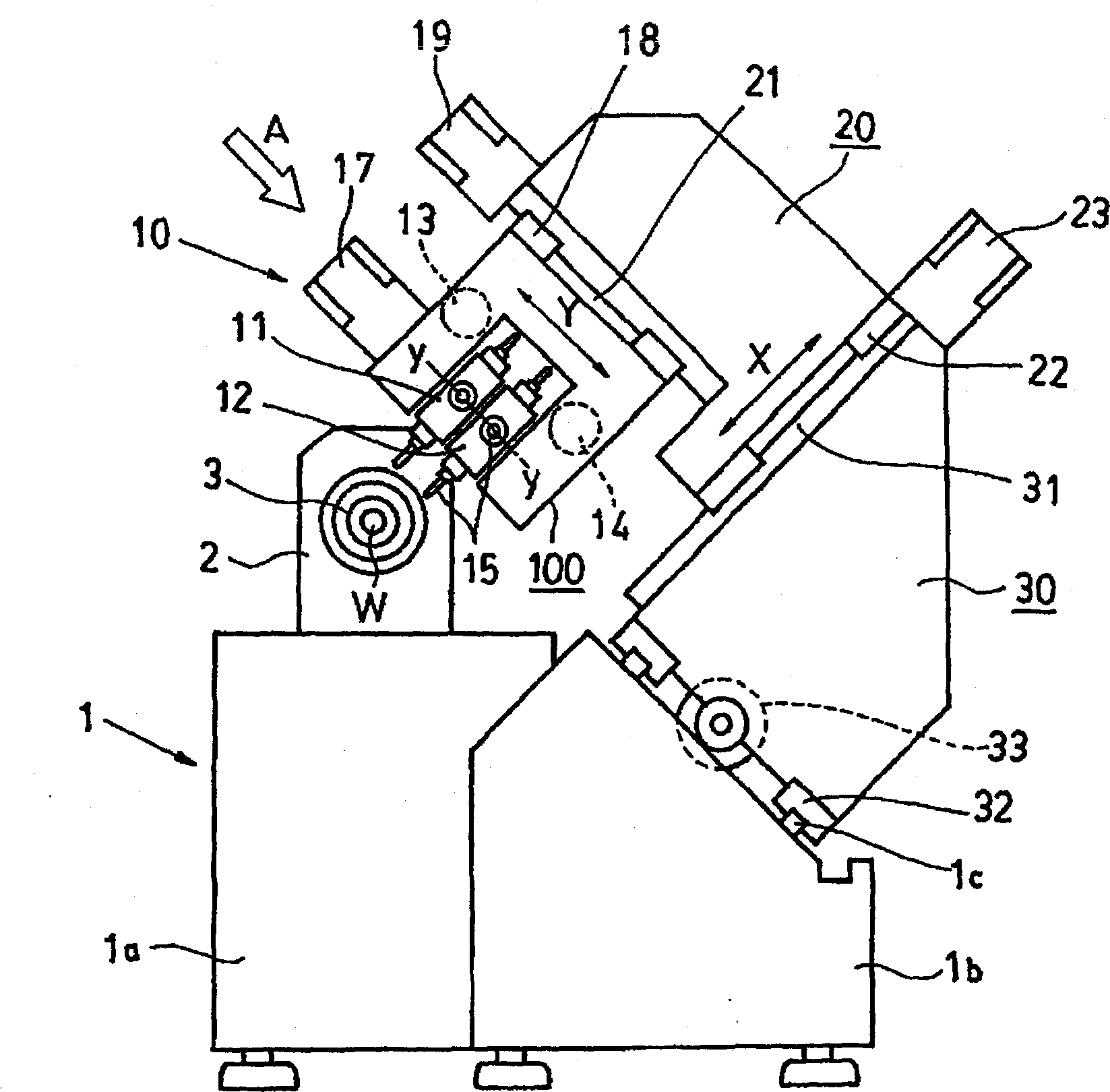

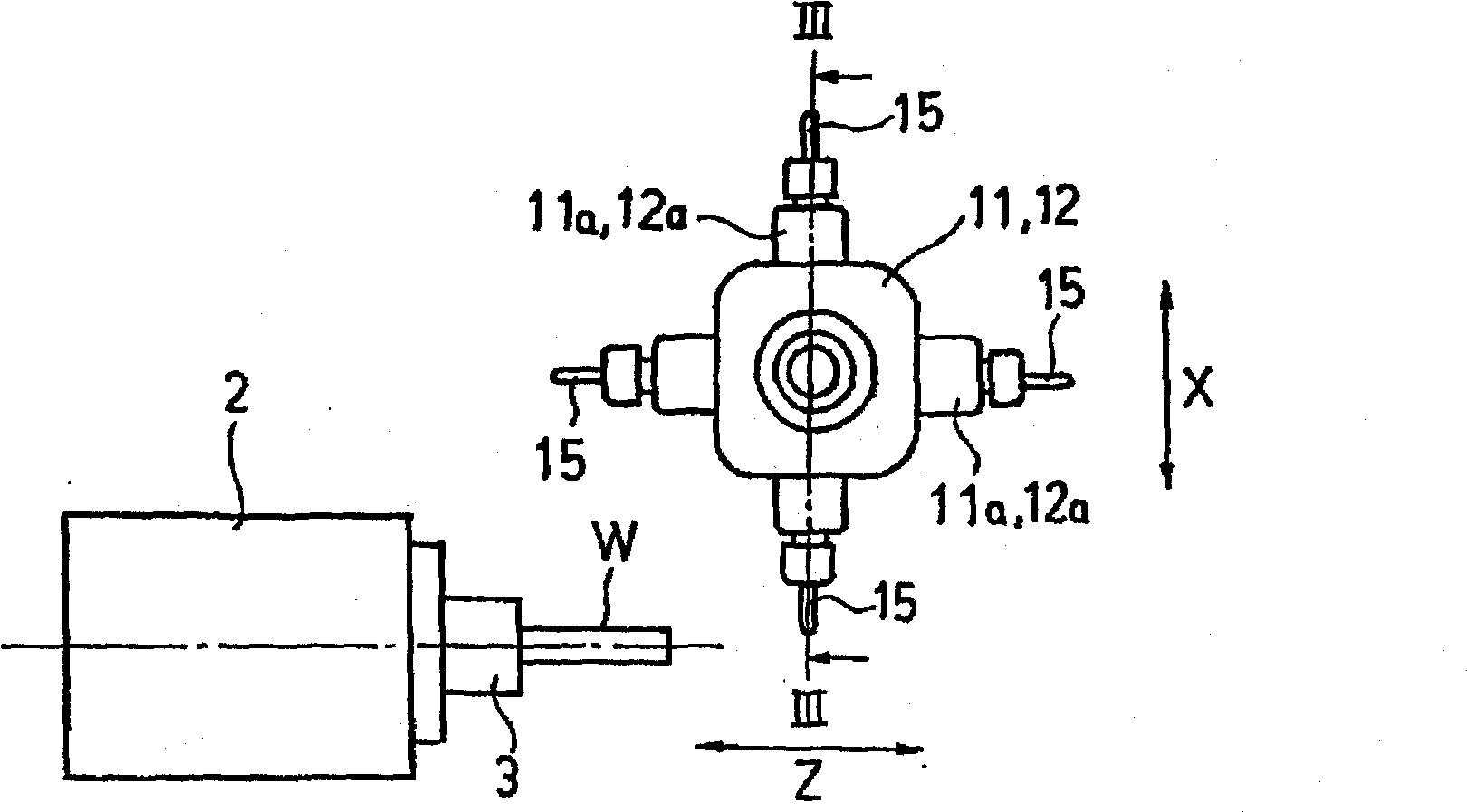

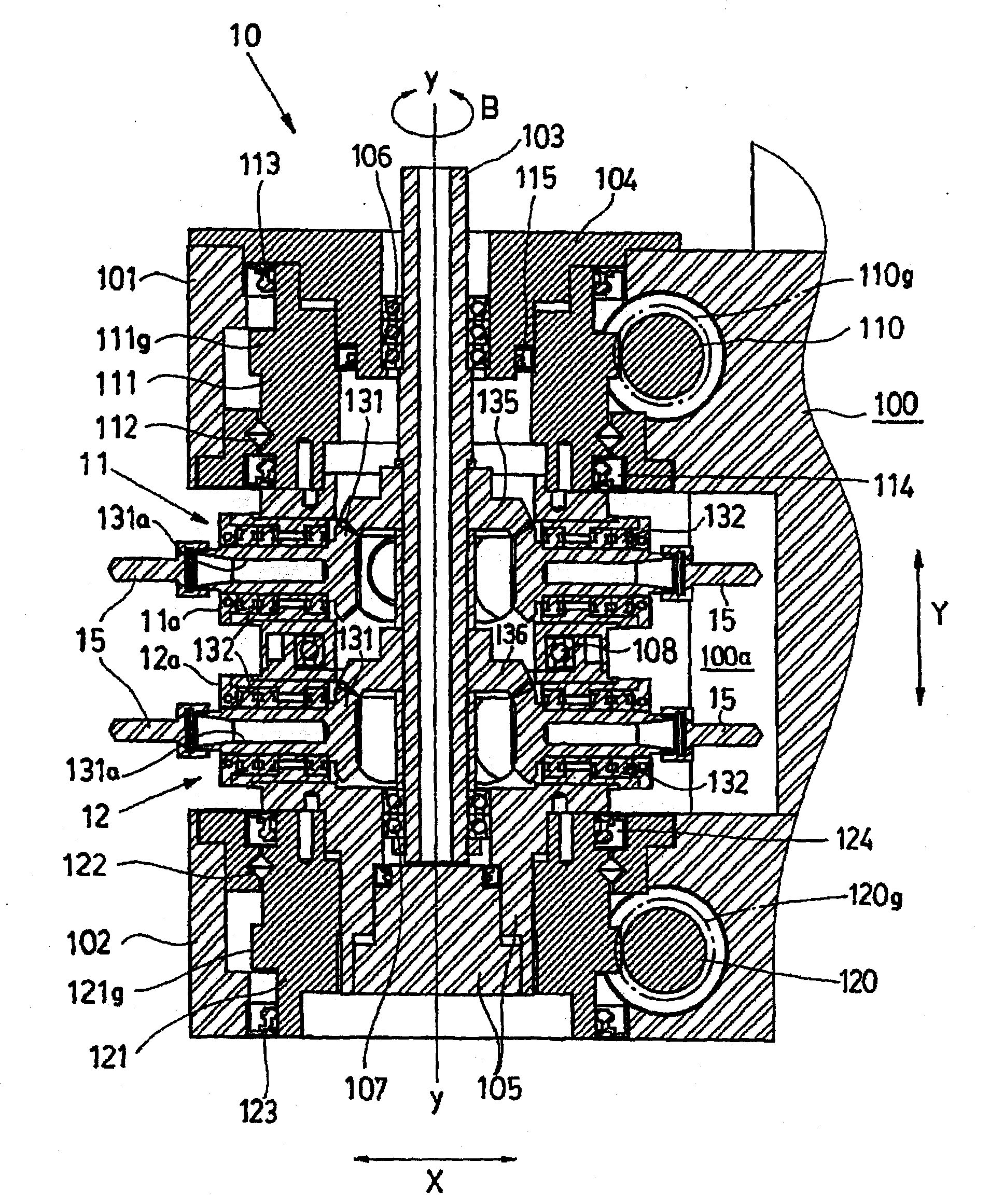

[0065] First, through Figure 1 ~ Figure 3 A configuration example of the composite machining lathe according to the invention and a basic configuration example of the tool holder according to the invention included in the composite machining lathe will be described.

[0066] figure 1 It is a schematic front view showing the overall configuration of this compound machining lathe, figure 2 means from figure 1 The relationship between the turret tool holder and the main shaft of the tool holder seen in the direction of the middle arrow A. image 3 Zoomed in along figure 2 The overall longitudinal section of the tool holder on the line III-III shows its internal structure.

[0067] exist figure 1 In this case, a headstock 2 supporting a freely rotatable spindle 3 is placed on a headstock support portion 1 a of a machine bed 1 . The headstock 2 can be mov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com