Frequency-variable acoustic film resonator, filter and communication apparatus using the same

A resonator and variable technology, applied in the field of filters, can solve the problems of affecting the characteristics of sound film resonators, deterioration of filter characteristics, and inability to be variable at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

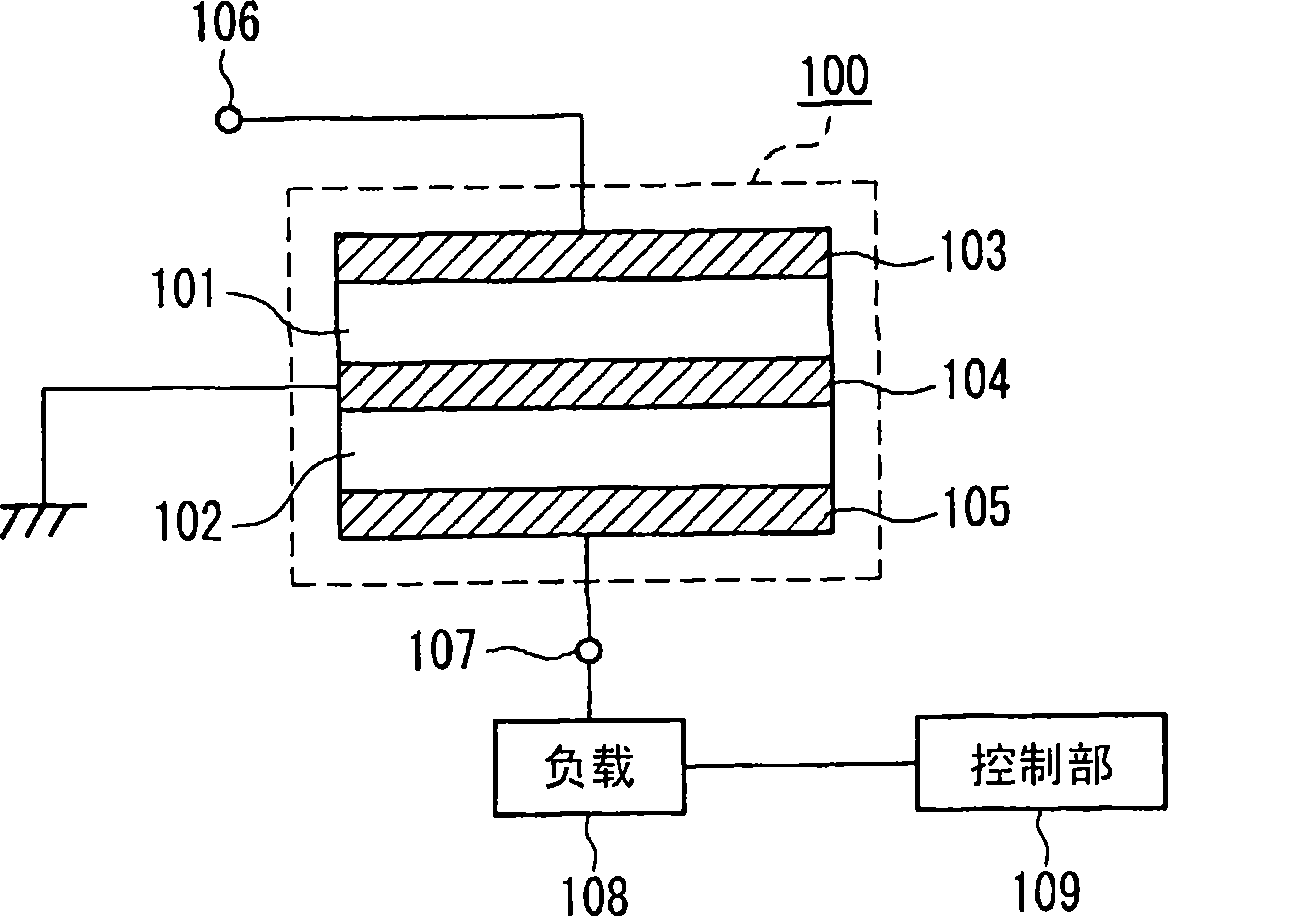

[0096] Figure 1A It is a block diagram of the frequency variable acoustic thin film resonator according to Embodiment 1 of the present invention. Figure 1B is its equivalent circuit diagram.

[0097] exist Figure 1A Among them, the acoustic thin film resonator 100 has a first piezoelectric body 101 and a second piezoelectric body 102 which are stacked. The first piezoelectric body 101 is sandwiched between the first electrode 103 and the second electrode 104 , and the second piezoelectric body 102 is sandwiched between the second electrode 104 and the third electrode 105 . The input terminal 106 is connected to the first electrode 103 , the second electrode 104 is connected to GND, and the output terminal 107 is connected to the third electrode 105 . A load 108 is also connected to the third electrode 105 , and the value of the load 108 is controlled by a control unit 109 .

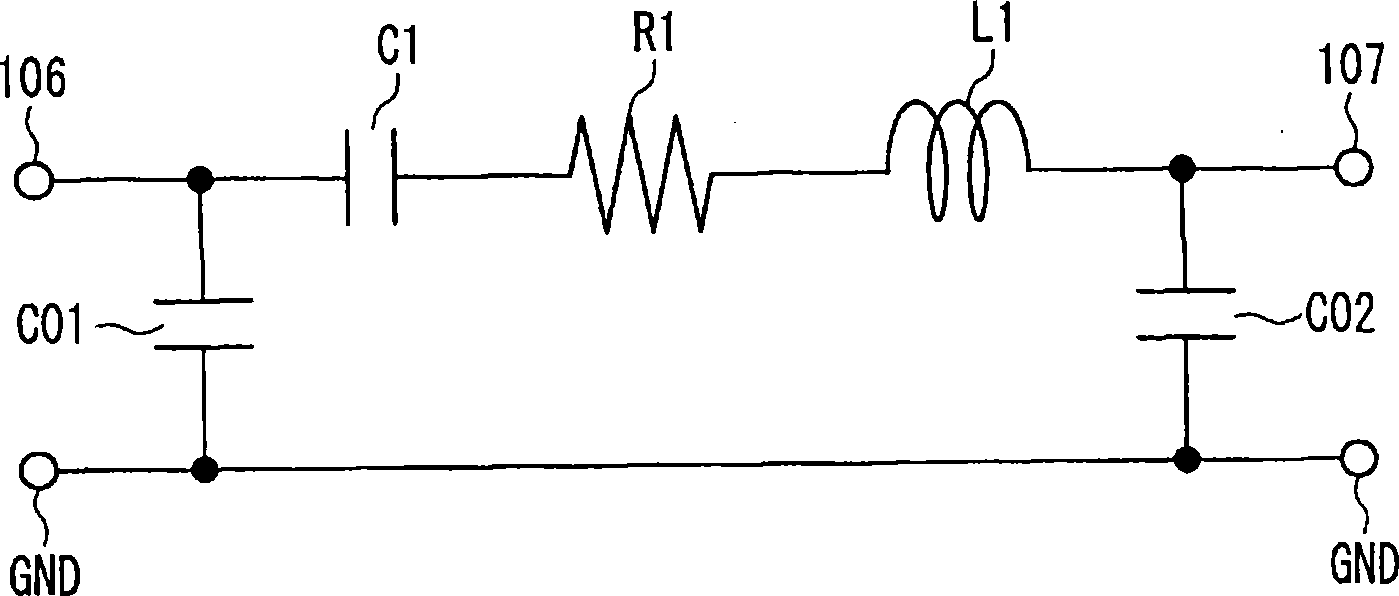

[0098] like Figure 1B As shown, the acoustic thin film resonator 100 can be represented by an...

Embodiment approach 2

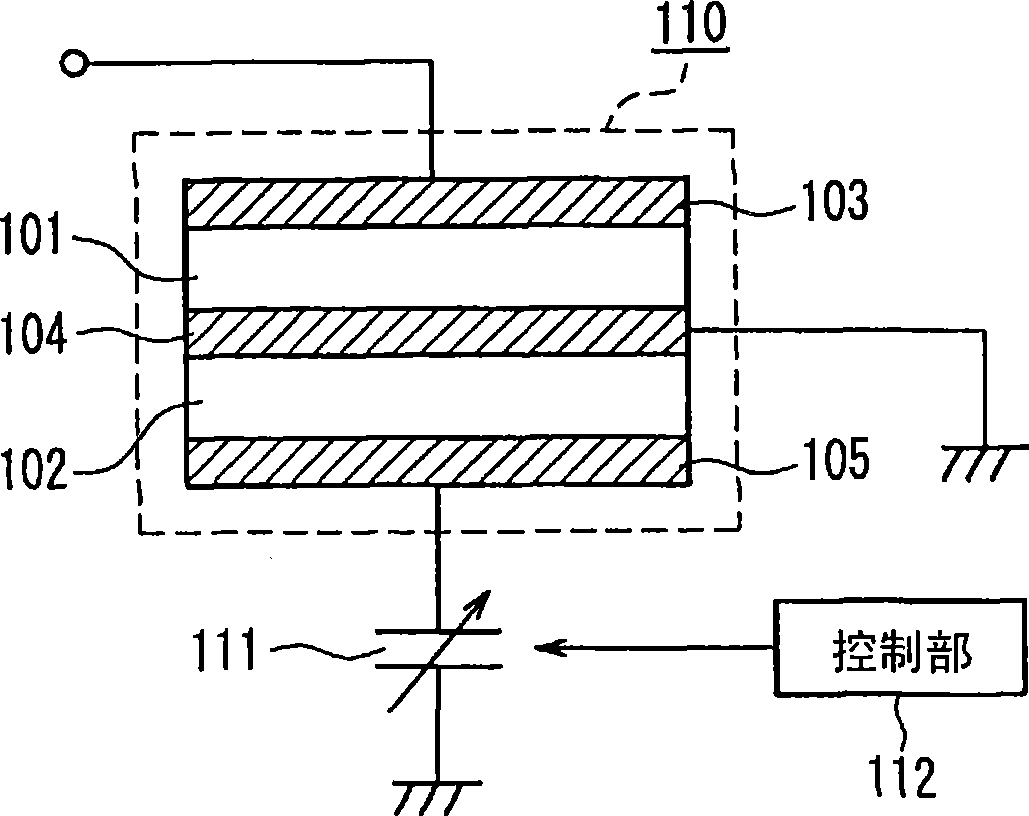

[0116] Figure 9 It is a block diagram of a frequency variable acoustic thin film resonator according to Embodiment 2 of the present invention. The difference between this embodiment and Embodiment 1 is that instead of Figure 1A The load 108 shown is provided with a switching element 201 and a control unit 202 for controlling the switching element 201 is provided.

[0117] In addition, the structure and operation of the acoustic thin film resonator 200 are the same as those of the acoustic thin film resonator 100 of Embodiment 1, and the same reference numerals are attached to the same elements, and repeated descriptions are omitted.

[0118] In the frequency variable acoustic thin film resonator of the present embodiment configured as described above, the following features are exhibited by providing the switching element 201 .

[0119] First, by using the switching element 201 operable in the open state and the short-circuit state as the load, changing the load according ...

Embodiment approach 3

[0122] The reference indicates the characteristic change with respect to the film thickness change of the piezoelectric body and the electrode Figure 11 , and the frequency-variable acoustic thin film resonator according to Embodiment 3 will be described. The frequency-variable acoustic thin film resonator in this embodiment has substantially the same Figure 1A The same structure is shown in which the first piezoelectric body and the second piezoelectric body are stacked.

[0123] Figure 11 shows the structure of the frequency-variable acoustic thin film resonator shown in Embodiment 1 ( Figure 1A ), the thickness is fixed using Mo as the electrode material, AlN is used as the piezoelectric material, and the characteristics obtained by changing the film thicknesses of the first piezoelectric body 101 and the second piezoelectric body 102 are calculated.

[0124] exist Figure 11 In the graph, the horizontal axis represents the film thickness ratio P / T of the film thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com