Aluminum foil corrosion technique for electrolytic capacitor

An electrolytic capacitor and process technology, applied in the direction of electrolytic capacitors, capacitors, circuits, etc., can solve the problems of small surface contact area of foil, high contact resistance, reduced electrical performance of aluminum electrolytic capacitors, etc., to improve electrical performance, reduce contact resistance, The effect of protecting the uncorroded part

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Take an aluminum foil with a thickness of 105 μm and perform the following treatments in sequence:

[0014] After adopting the method described in patent application 200810066667.6 to carry out pretreatment, AC pre-corrosion and intermediate corrosion treatment on aluminum foil, follow the steps below for subsequent corrosion treatment:

[0015] (1) Dip the aluminum foil into a mixture of 22wt% hydrochloric acid, 0.15wt% sulfuric acid, 0.35wt% oxalic acid and 2.5wt% aluminum trichloride at a temperature of 40°C and a corrosion current density of 4A / dm 2 , power frequency is 20Hz, electricity is 480C / dm 2 , which is the first-level AC deep corrosion;

[0016] (2) Carry out the first level chemical corrosion in the aluminum foil after the treatment of step (1) in the mixed solution of 20wt% hydrochloric acid, 0.1wt% sulfuric acid, 0.1ppm cupric chloride, 2wt% aluminum chloride, the temperature is 60°C, treatment time 1 minute;

[0017] (3) Carry out the second-stage AC...

Embodiment 2

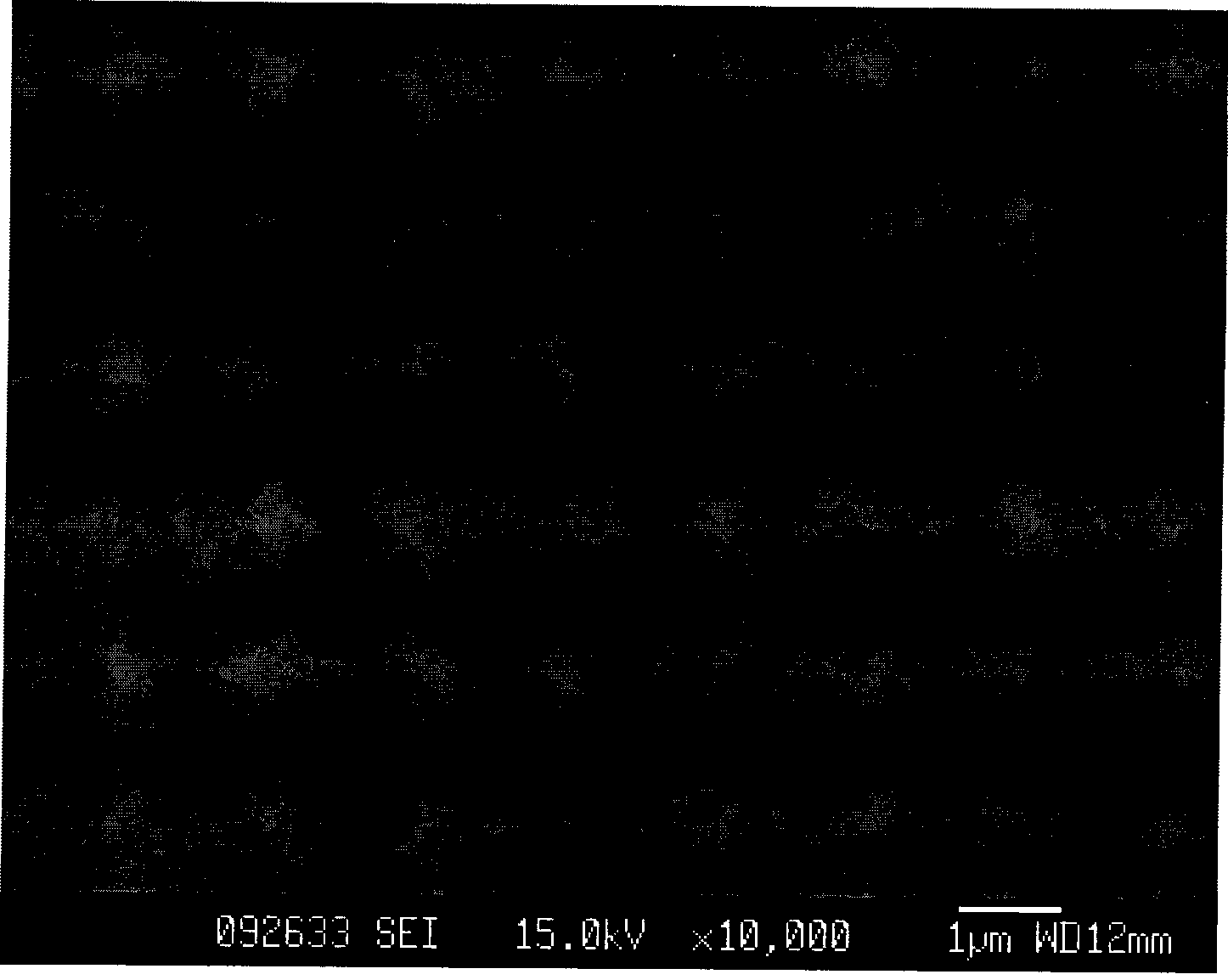

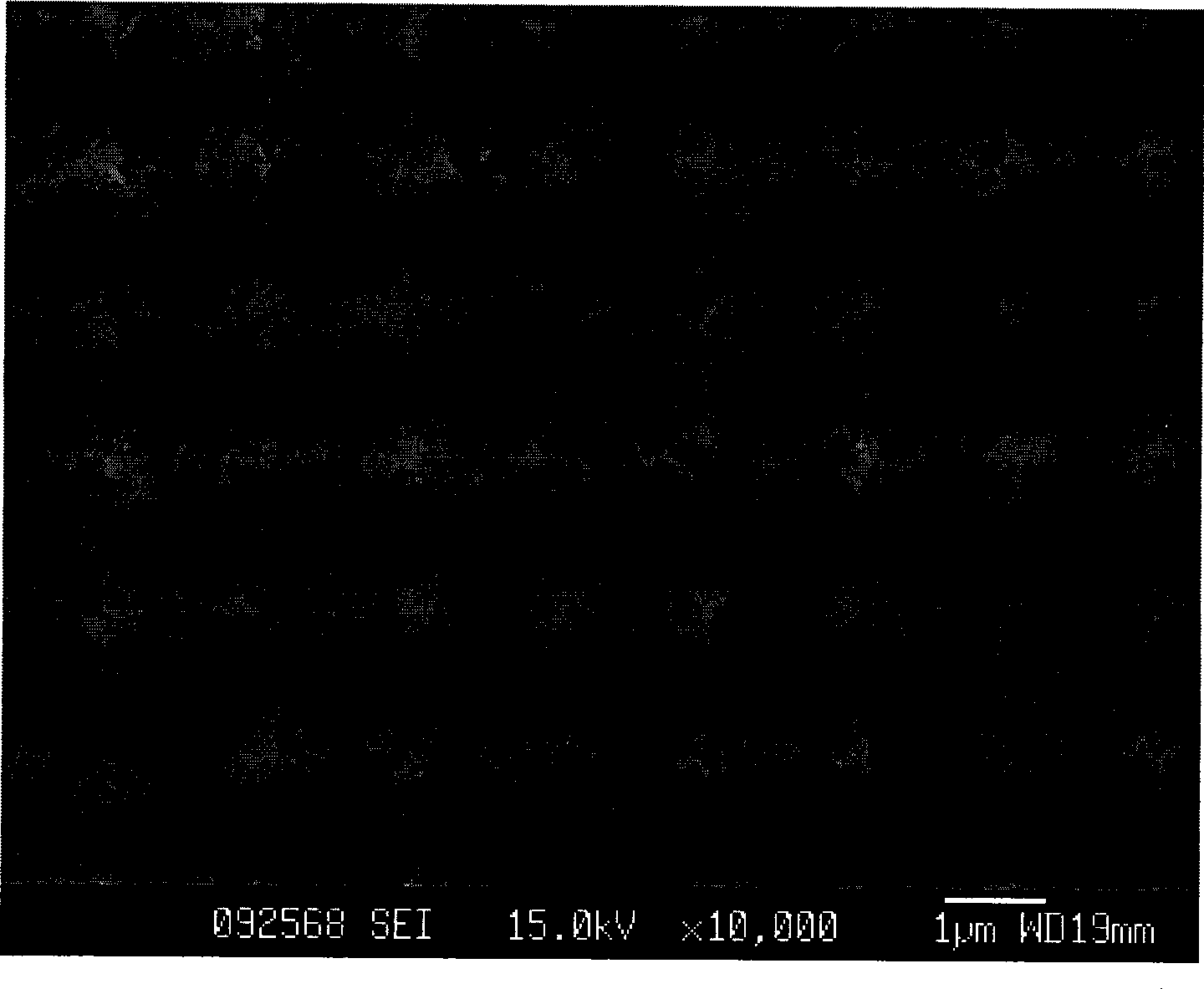

[0030] Using the same aluminum foil as in Example 1, it was etched. The process and process conditions were basically the same as in Example 1, only the frequency of the power supply in the AC deep etching process was adjusted to 30 Hz. The aluminum foil treated above is subjected to the usual post-treatment, and then the performance of the corroded foil is tested. Inspection condition is also identical with embodiment 1, records that its specific volume is 77.2 μ F / cm 2 , the weight loss is 1.09g / dm 2 , the tensile strength is 22.3N / cm, and the number of bending resistance is 89 times. Observing the scanning electron microscope image of the corroded foil, the surface hole morphology is rectangular, and the corrosion develops vertically in the depth direction. The test results show that the specific volume can be increased by 10% while keeping the mechanical properties of the aluminum foil basically unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Specific volume | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com