Pre-control method for preventing inclination of sinking well

A caisson and shaft wall technology, applied in the fields of municipal engineering and civil engineering, can solve the problems of difficult deviation correction, no method of pre-controlling the inclination of the caisson, and inclination of the caisson, so as to avoid the inclination of the caisson.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

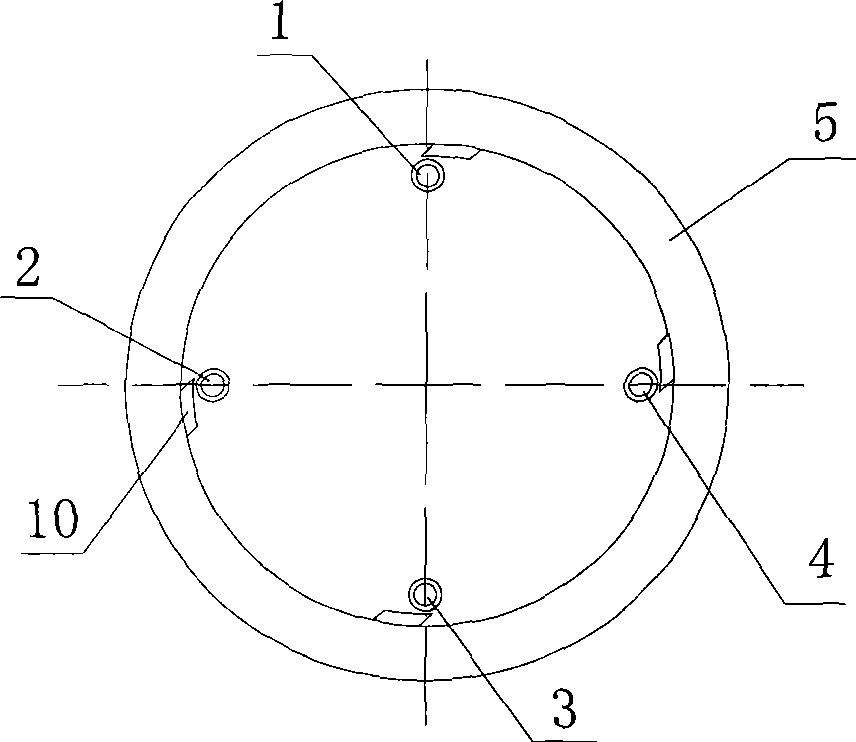

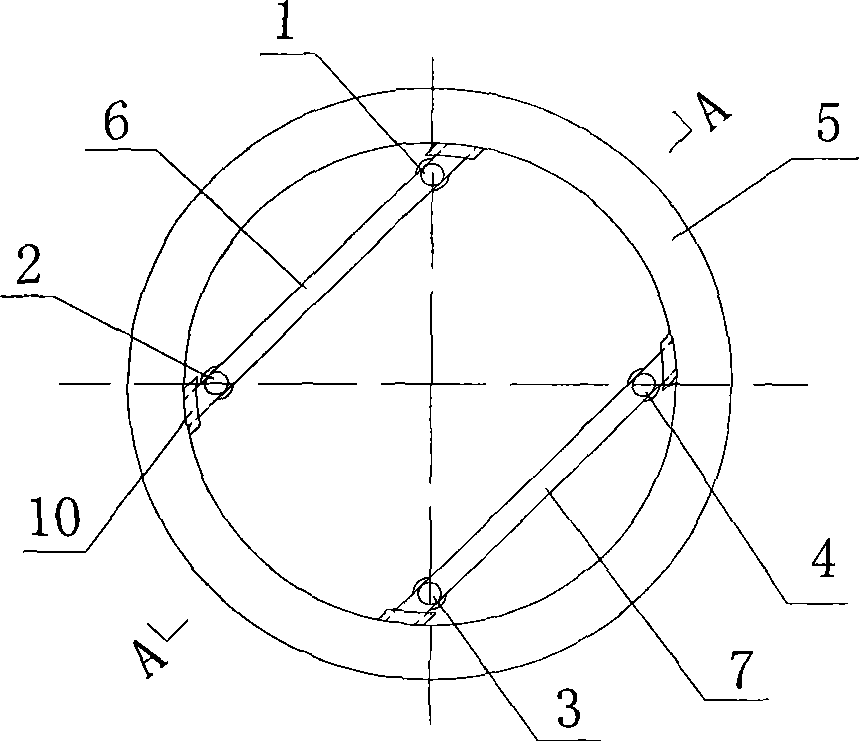

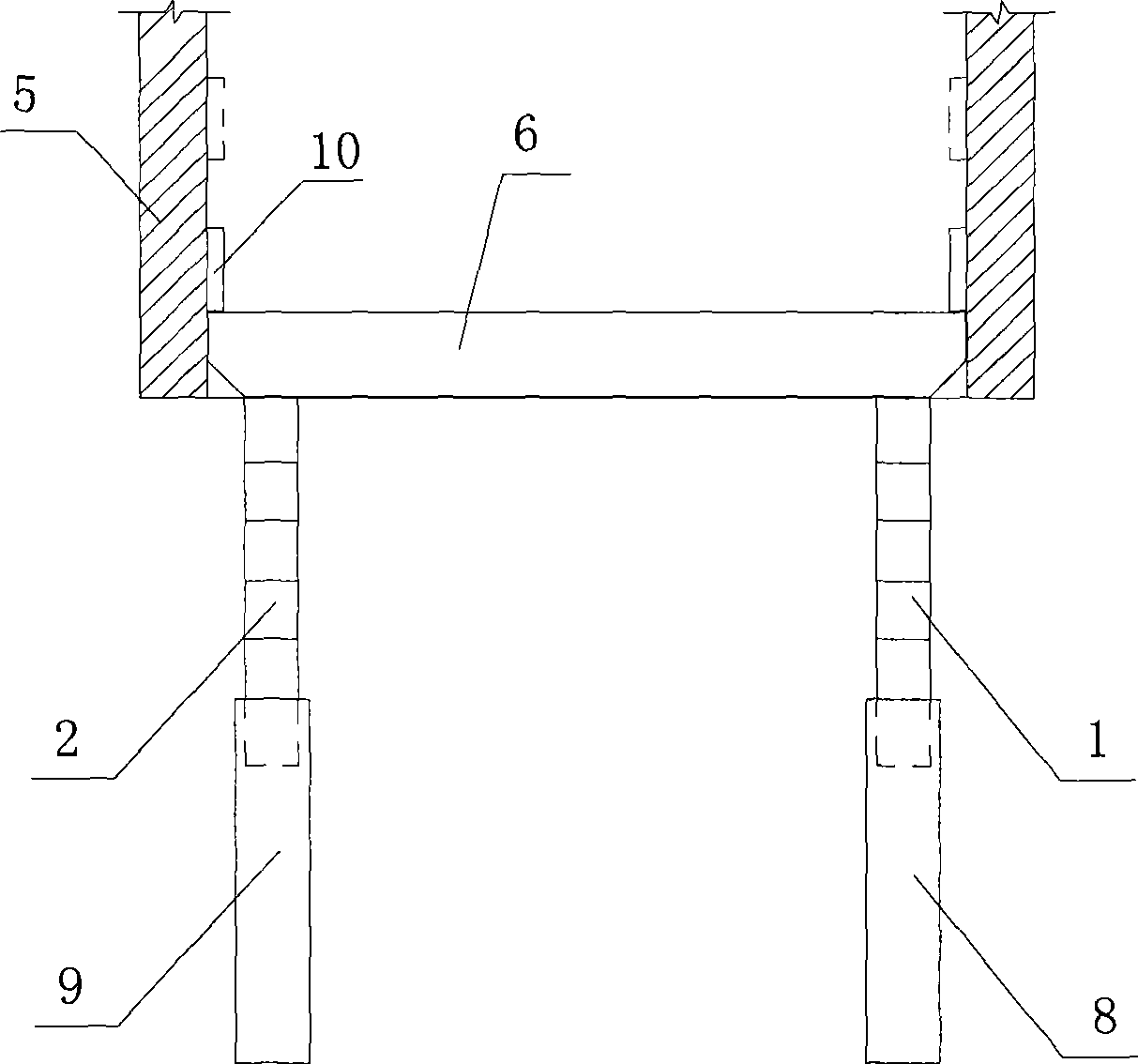

[0023] Such as figure 1 , figure 2 , image 3 As shown, the pre-control method to prevent caisson tilting includes the following steps:

[0024] 1), before the sinking of the caisson, construct the first cast-in-place pile 8, the second cast-in-place pile 9, the third cast-in-place pile, and the fourth cast-in-place pile in the caisson. layout (clear distance), 90° to each other, the bottom of the 4 cast-in-situ piles is located below the design elevation of the bottom of the caisson (the depth of the 4 cast-in-place piles should meet the force requirements), and the tops of the 4 cast-in-place piles Located at the design elevation of the bottom of the caisson; then insert steel structural columns on the top of the four cast-in-place piles (the steel structural columns are fixed on the top of the cast-in-place piles, respectively the first steel structural column 1, the second steel structural column 2, the third Steel structure column 3, the fourth steel structure column ...

Embodiment 2

[0029] It is basically the same as Embodiment 1, except that: step 3) move all the steel corbels vertically up by 0.5m and fix them on the inner side of the caisson wall.

Embodiment 3

[0031] It is basically the same as Embodiment 1, except that: step 3) moving all the steel corbels vertically up 3m and fixedly installing them on the inside of the well wall of the caisson.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com