Imaging system for component axial centering detection apparatus

An imaging system and detection device technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems affecting the centering operation of two objects, cumbersome operation, complex structure, etc., and achieve intelligent equipment debugging, simple operation, The effect of improving the centering accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

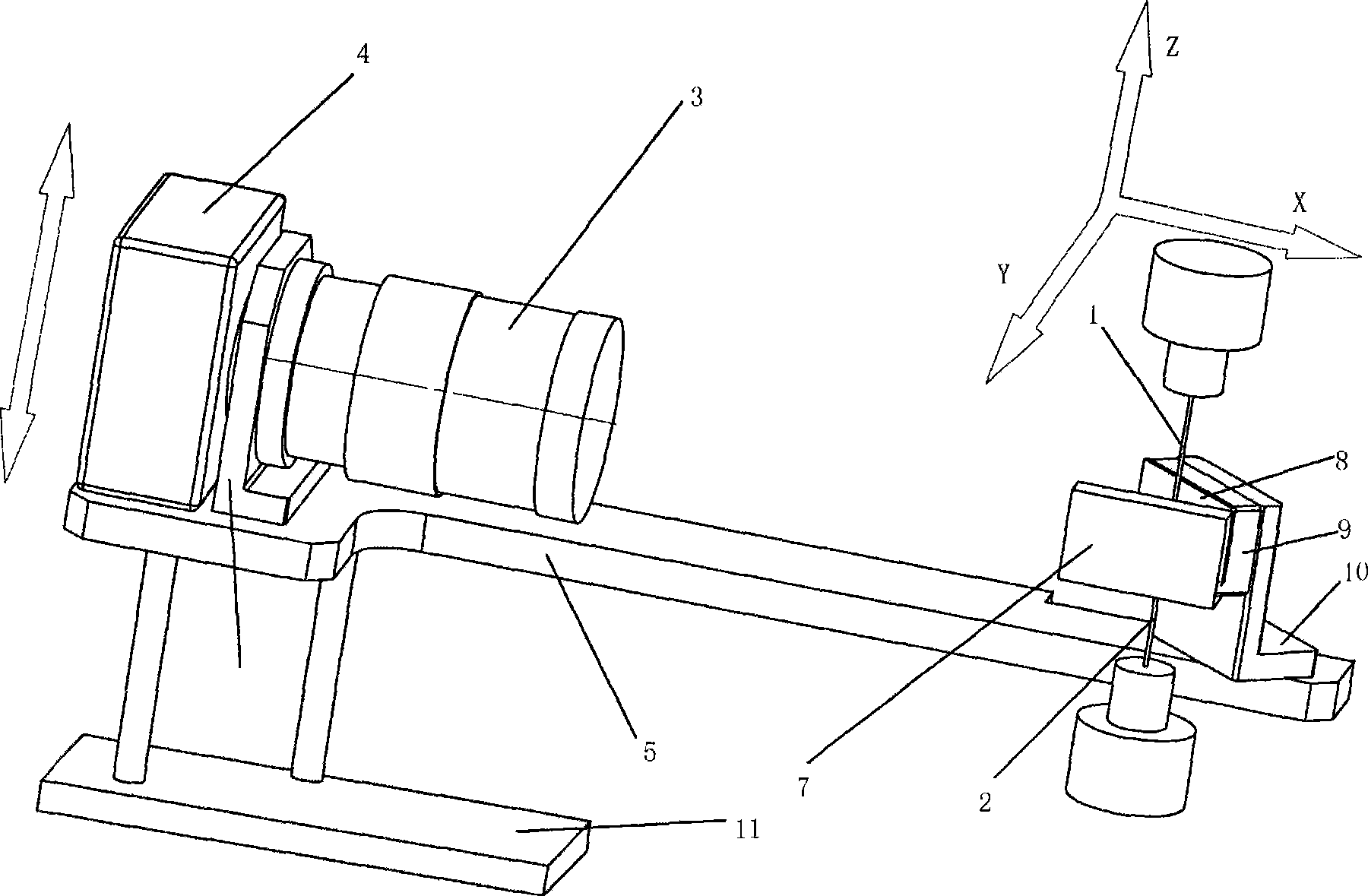

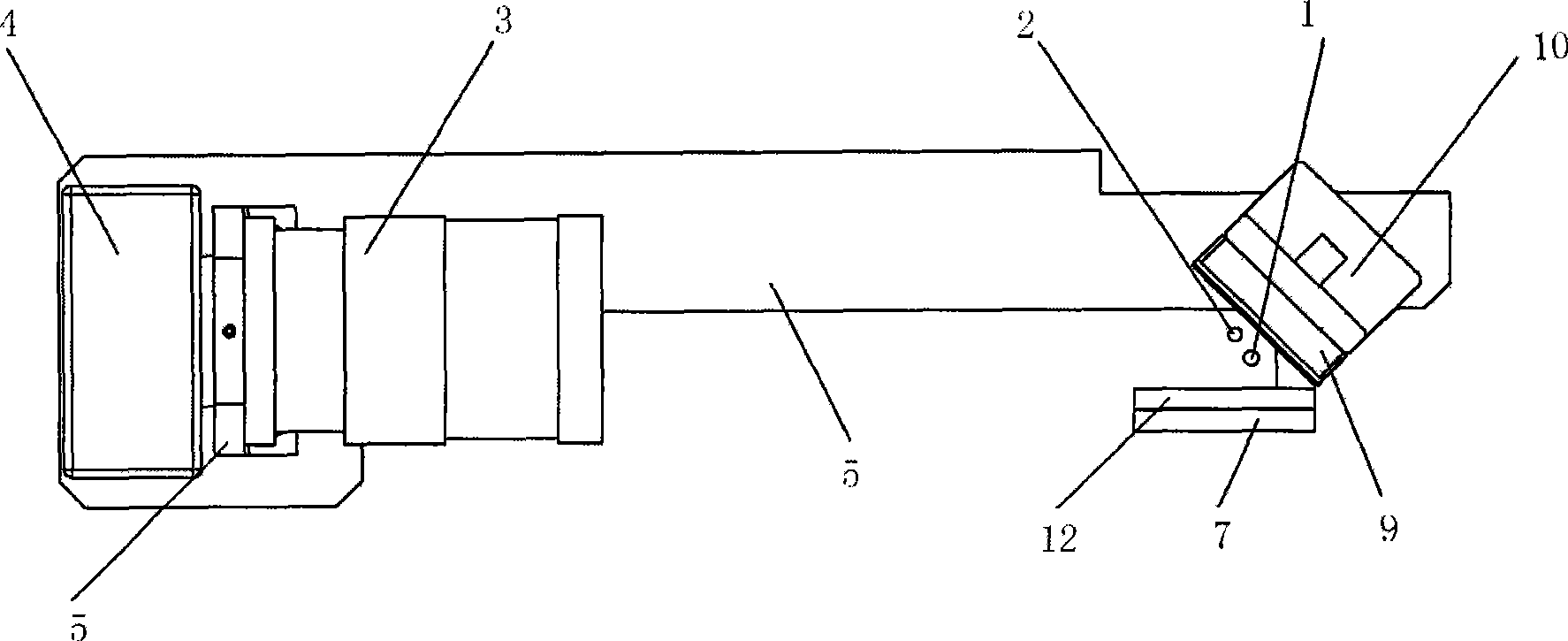

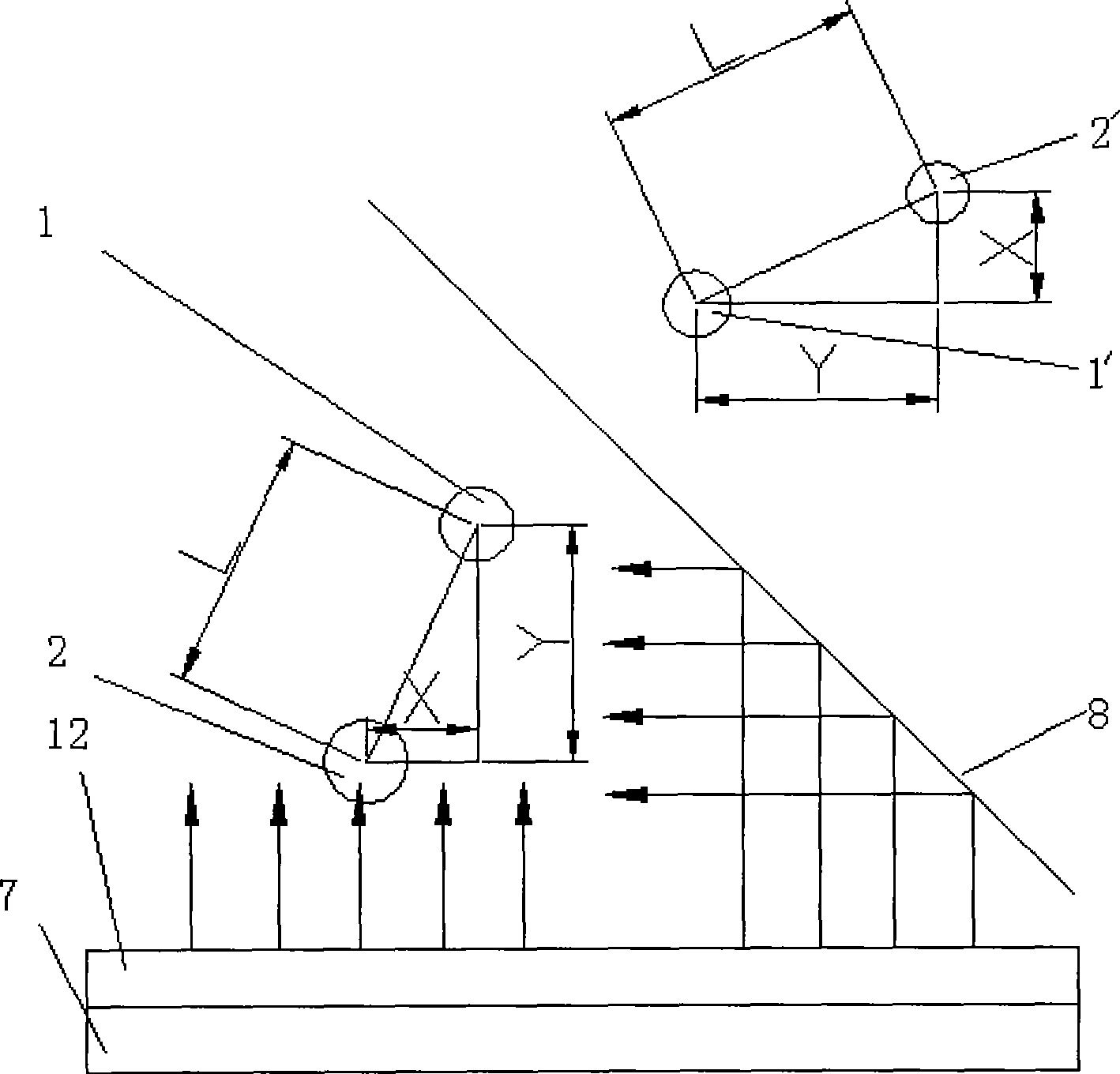

[0023] like figure 1 , figure 2 As shown in the figure, the first needle-like object 1 to be aligned, and the second needle-like object 2 to be aligned, under normal circumstances, their volumes are very small, and for convenience of presentation, the figures are relatively enlarged; figure 1 The vertical arrow in the middle indicates the height adjustment direction of the device, and the space rectangular coordinate arrow indicates the adjustable direction of the needle-shaped object to be aligned.

[0024] The present invention includes a base 11, a support arm 5, an image acquisition unit, a plane mirror unit and a light source unit; the support arm 5 is located on the base 11 and can be adjusted up and down relative to the base in the vertical direction;

[0025] The image acquisition unit includes an electronic camera 4 and an optical lens 3, which are screwed together through an interface, and then fixedly connected to one end of the support arm 5 through a fixing brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com