Cutter-head of machine for making furrows

A ditching knife and ditching machine technology, applied in the direction of digging/covering ditches, soil movers/shovels, planting methods, etc., can solve the problems of clay soil that cannot be unearthed, weak deep ditching ability, and reliability reduce the problem, achieve the effect of improving the overall ditching ability, reducing the contact area, and reducing the cutting power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

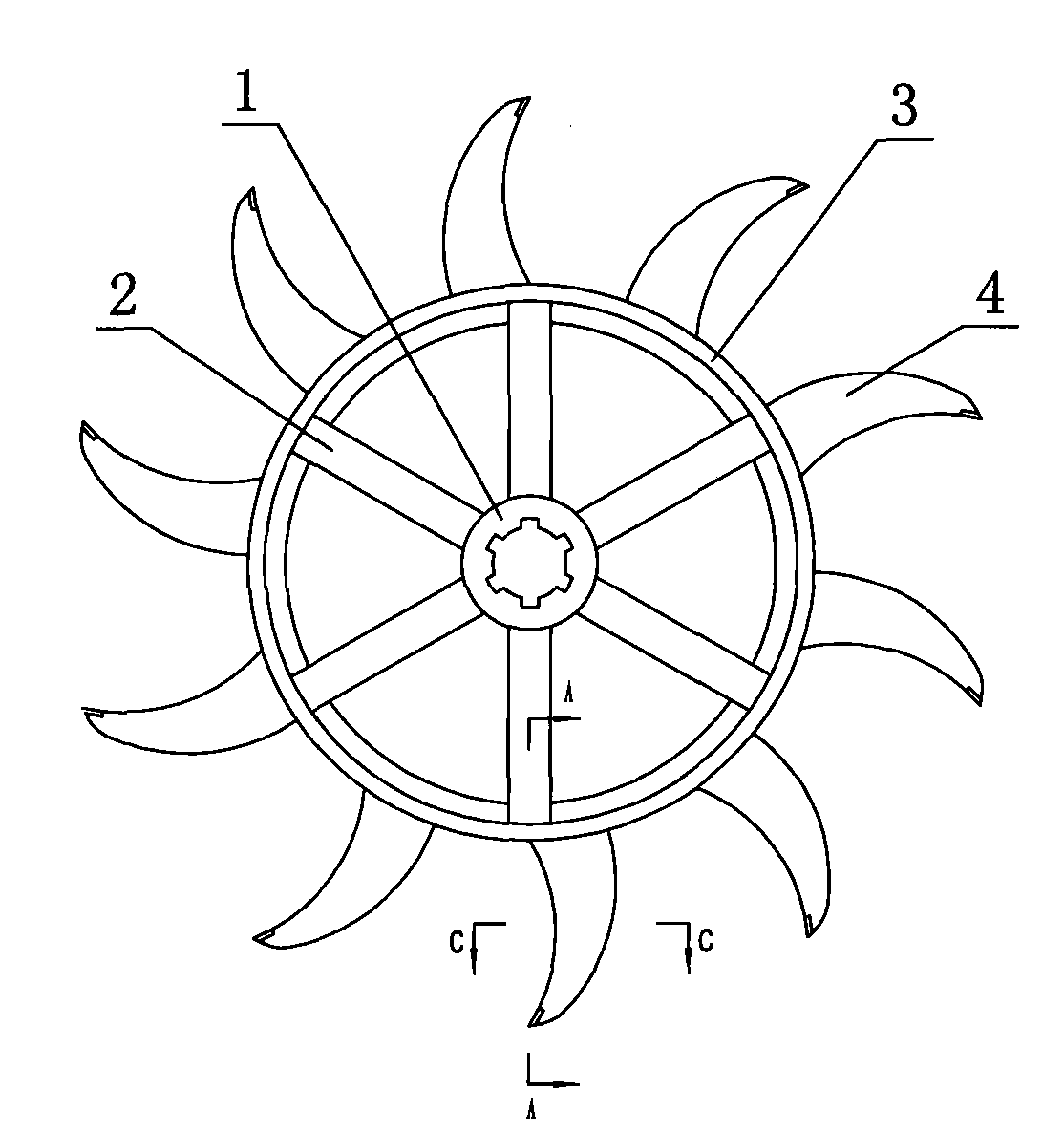

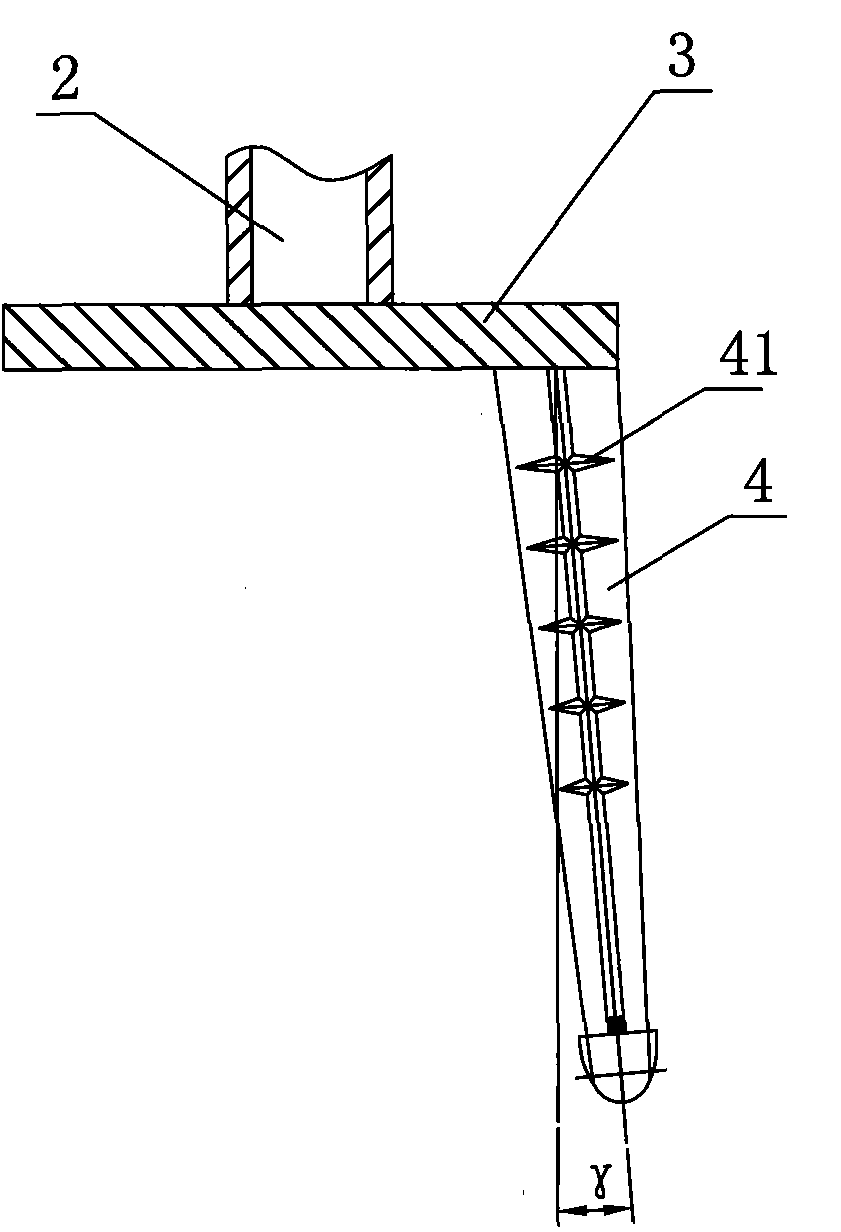

[0020] figure 1 Shown is the trencher cutter head of the present invention, including spokes 2, hub 1, annular knife holder 3 and at least one set of trenching knife sets, said trenching knife set including several trenching knives 4. The ditching knife 4 is fixed on the annular knife holder 3, and the annular knife holder 3 and the hub 1 are connected by the spokes 2, and the ditching knife 4 is in the shape of a hook. The ditching knives 4 are evenly arranged on the circumference of the annular knife seat 3 and arranged in a staggered order in the axial direction of the annular knife seat 3 .

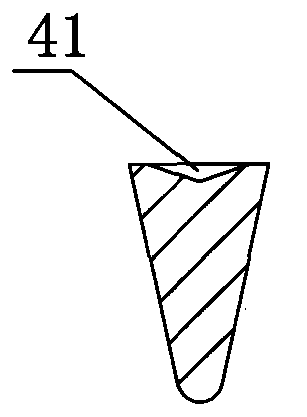

[0021] Such as figure 2 As shown, in order to facilitate trenching, the width of the annular knife seat 3 needs to be smaller than the width of the ditch, so the ditching knives 4 on the left and right sides are respectively inclined to the left and right γ=5°~8°, so that the knife head protrudes from the side of the knife seat Edge distance 5 ~ 8mm. Ditching cutter 4 is made up o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com