Offsetting printer

A technology of printing presses and racks, applied in printing presses, rotary printing machines, rotary printing machines, etc., which can solve the effects of printing quality stability and consistency, the inability to maintain bottom rollers and ink transfer systems, and the cost of letterpress printing machines Advanced problems, to achieve the effect of stable printing quality, good consistency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

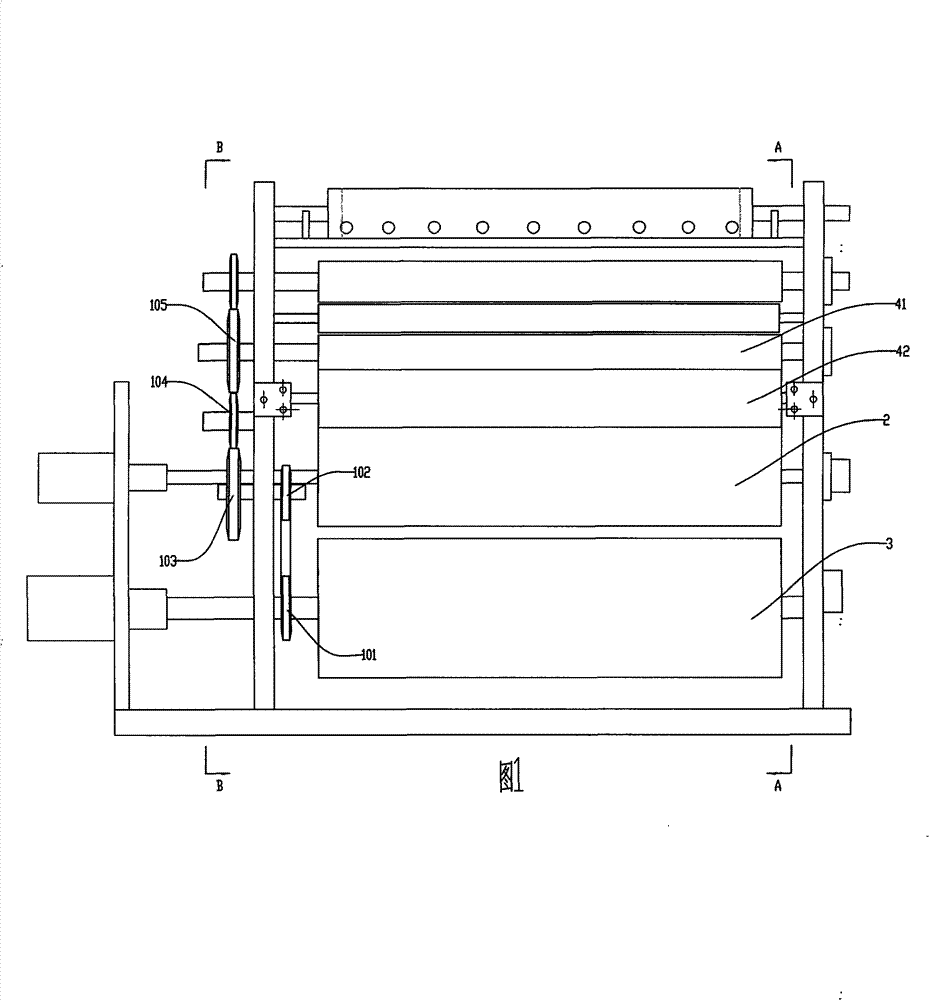

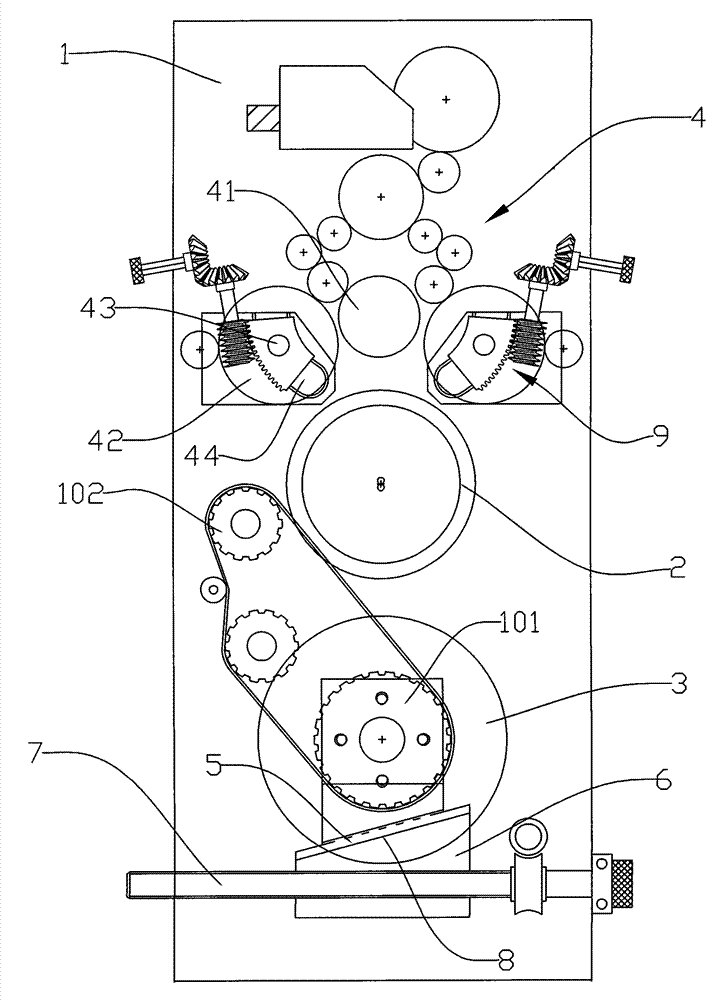

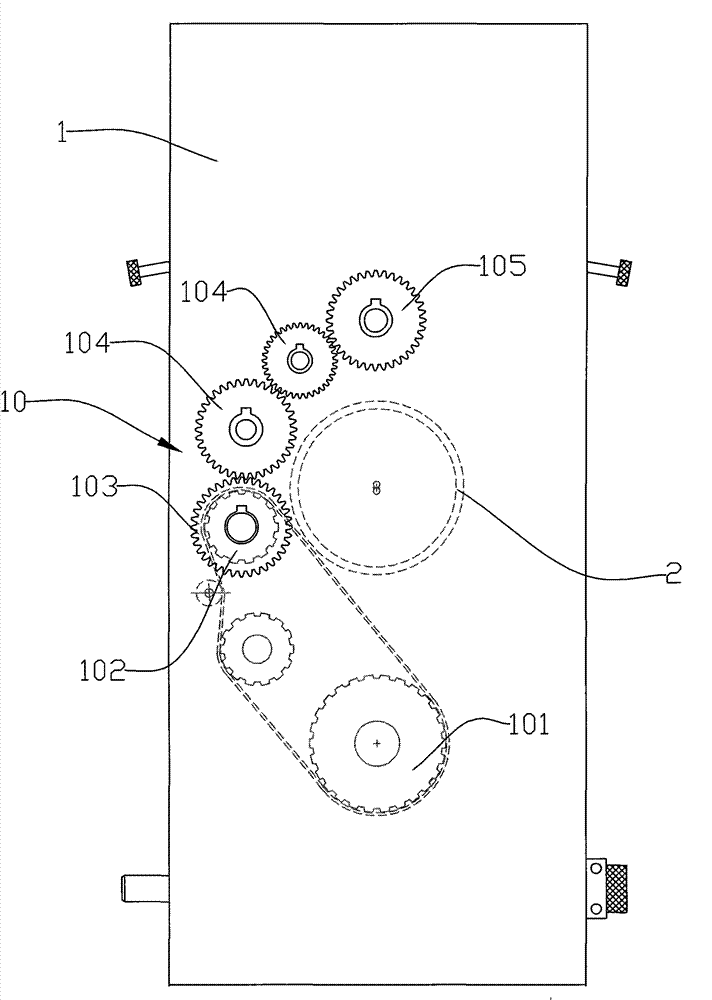

[0012] A letterpress printing machine such as figure 1 , figure 2 , image 3 , including a version roller 2 fixed on the frame 1, a bottom roller 3 located below the version roller, and an ink transfer mechanism 4 that transfers ink to the version roller. The version roller 2 and the bottom roller 3 are driven by different motors. The bottoms on both sides of the roller 3 are inclined planes 5, which are supported on the wedge-shaped block 6 at the bottom, and the wedge-shaped block is screwed on the screw rod 7 at the bottom of the frame 1. Consistent slope 8, rotating screw rod 7 wedge-shaped block moves along the screw rod direction, the slope at the bottom of the bottom roller slides relative to the slope at the top of the wedge-shaped block, so that the bottom roller is raised or lowered; The ink roller 42 clamps the version roller 2 from both sides of the upper part of the version roller 2, and at the same time is close to the ink roller 41 and the version roller 2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com