Electric accelerator pedal for vehicle

An electronic accelerator pedal and pedal arm technology, which is applied to the layout, transportation and packaging of vehicle components and power plant control mechanisms, can solve the problems of complex structure, poor cost-effectiveness, and many parts, and achieve a simplified and effective structure, and improve benefit, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

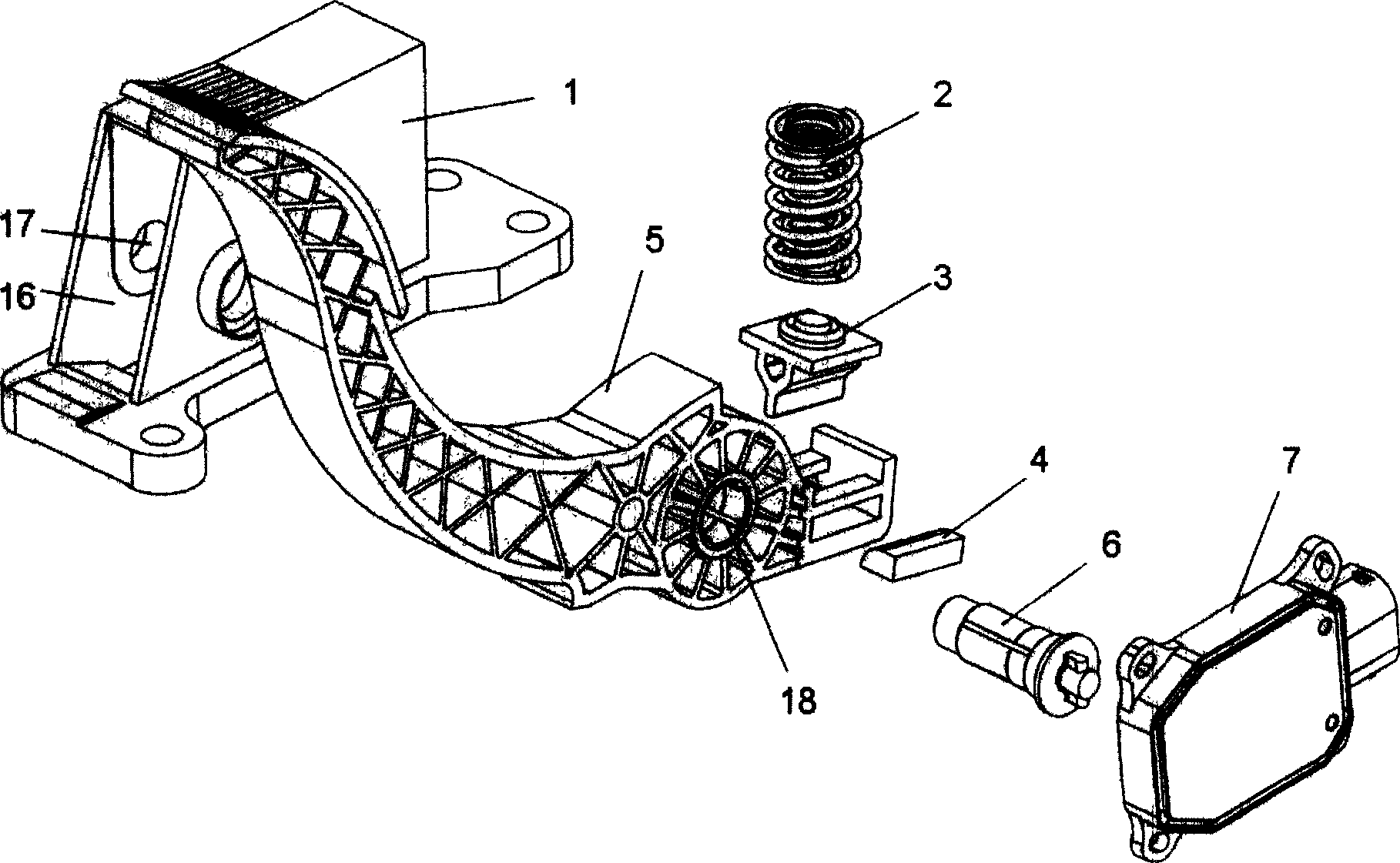

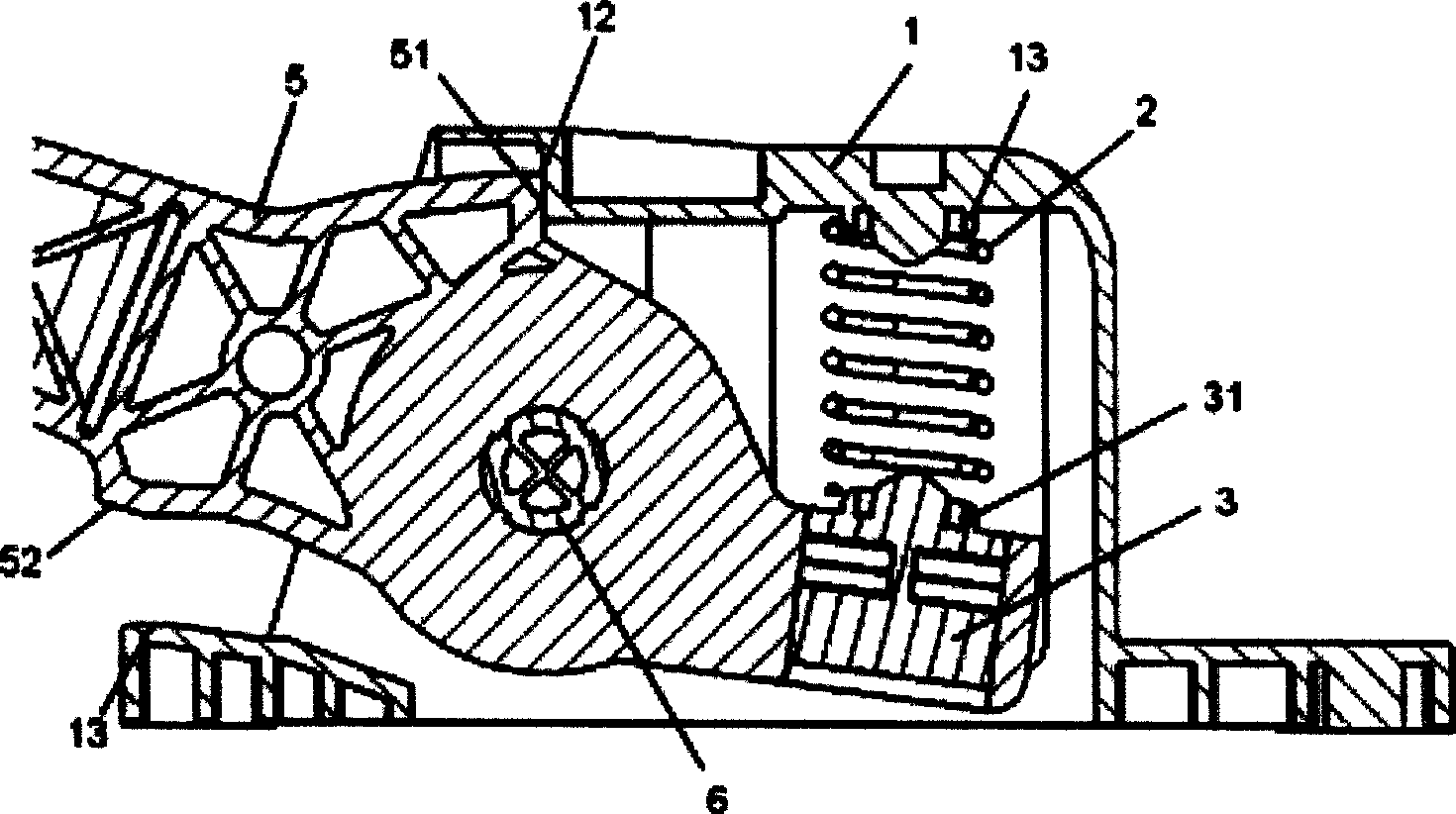

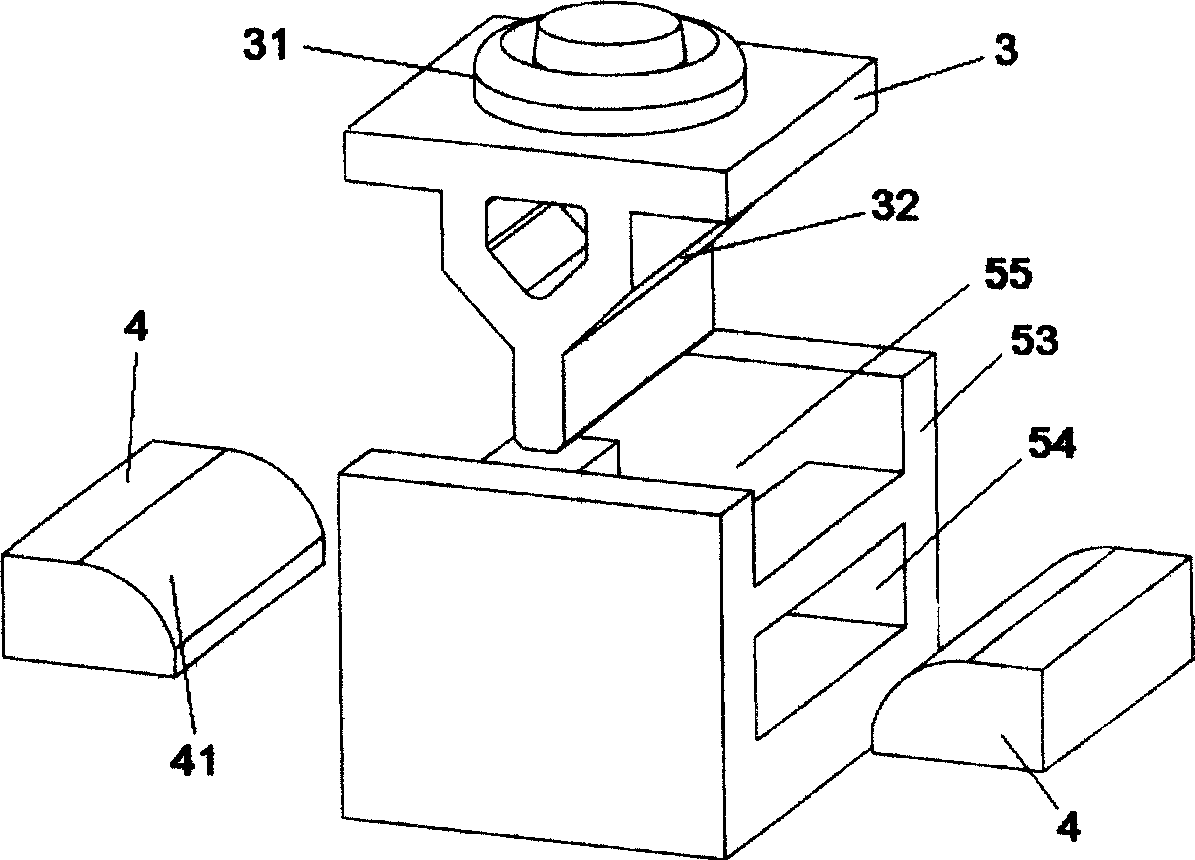

[0019] see figure 1 , 2 As shown, the electronic accelerator pedal of the present invention includes a housing 1 , a pedal arm 5 , a spring 2 , a spring support 3 , two friction elements 4 , a rotating shaft 6 and a sensor module 7 .

[0020] The front end of the housing 1 has an opening 16 , and the left and right side walls are provided with shaft holes 17 . The tail of the pedal arm 5 is provided with a shaft hole 18 . Insert the pedal arm 5 into the housing 1 from the opening 16 of the housing 1, the left and right direction is limited by the inner wall of the housing 1, and then the rotating shaft 6 is inserted into the shaft hole 17 of the housing 1 and the rotating shaft hole 18 of the pedal arm 5, so that The pedal arm 5 is installed in the housing 1 and can be rotated. The rotating shaft 6 can be a stepped shaft, and at this time, the rotating shaft 6 can only be inserted into the pedal arm 5 through the opening 16 on one side of the housing 1 . Through the radial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com