Ship drag-reduction method using atmospheric pressure

An atmospheric pressure and ship technology, which is applied in the ship field, can solve the problems of the installation position, angle and size design of the transom.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

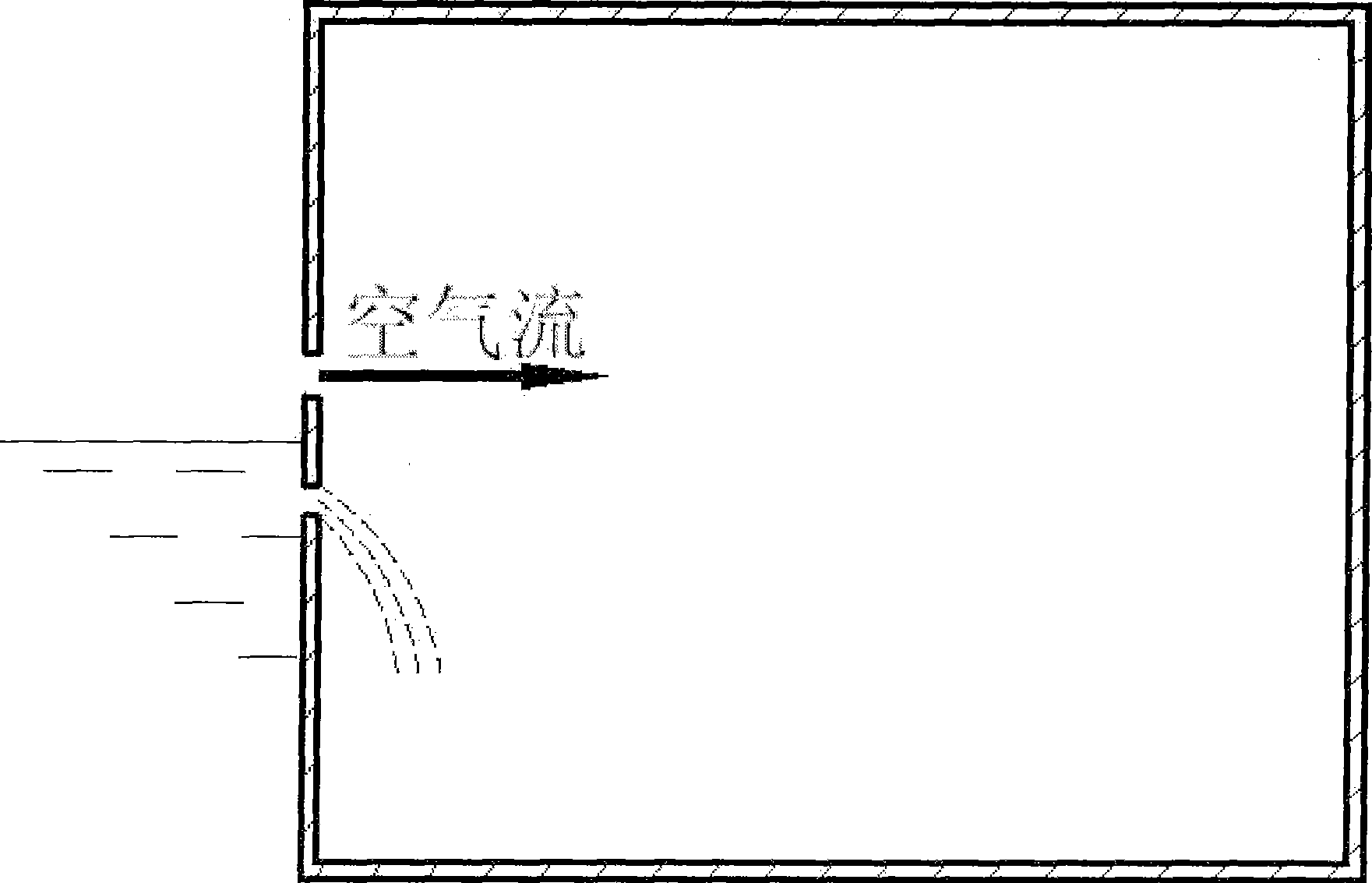

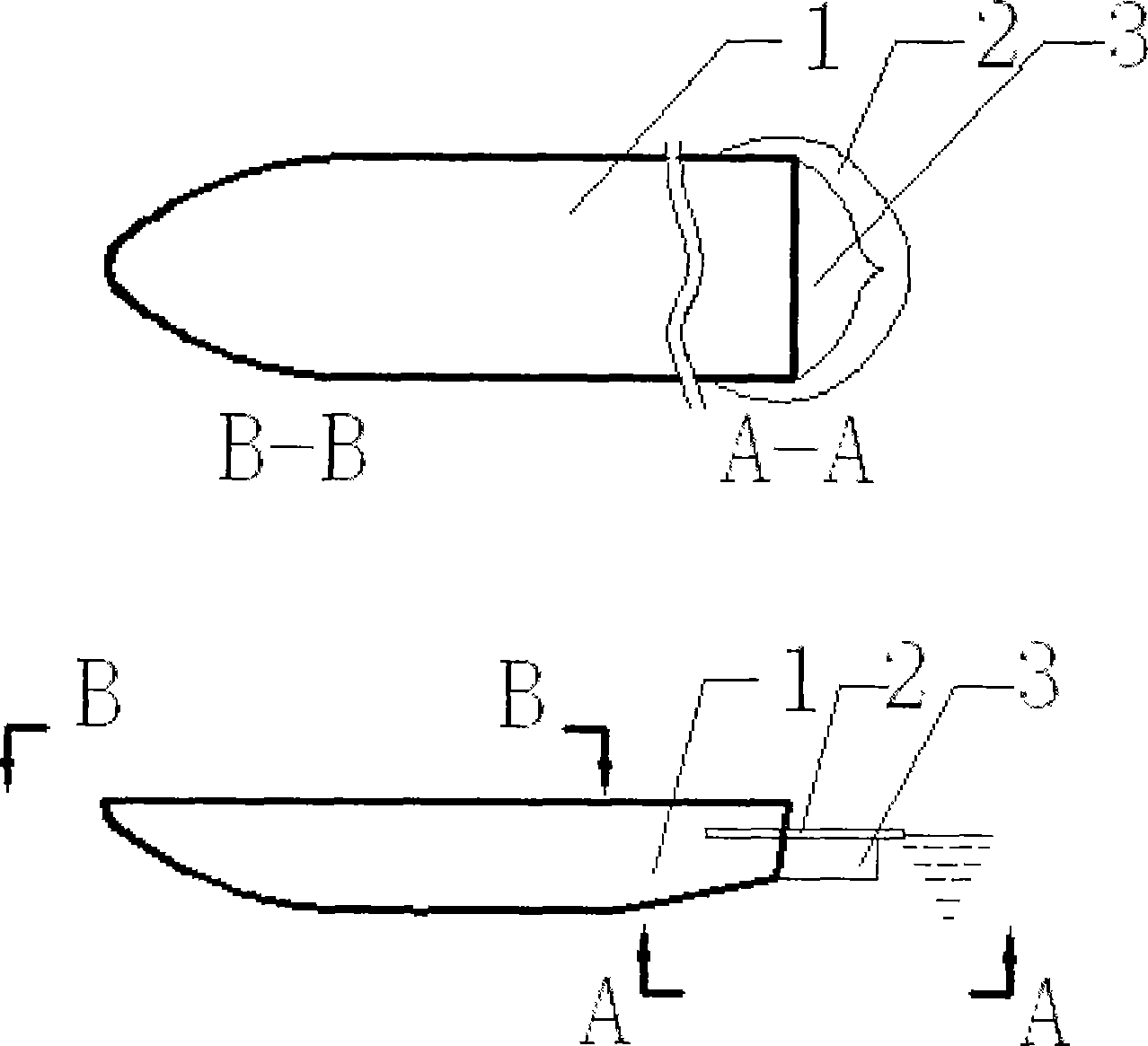

[0021] The effect of the water-air isolation strip of the present invention is to separate water and air at the horizontal plane position outside the hull, and its shape can be any shape. In order to reduce costs, a fixed installation method is generally adopted. Theoretically, the water-air isolation zone adopts a thin plate, the trim angle is designed to be 0 degrees, and the bottom is close to the water surface. The air isolation zone is designed to be adjustable. Small adjustments to the depth of the water-air isolation zone in water and the angle between the water-air isolation zone and the hull can better adapt to the different navigation states of the ship to achieve better results. In addition, the water vapor isolation zone can be installed all around the hull or partially installed.

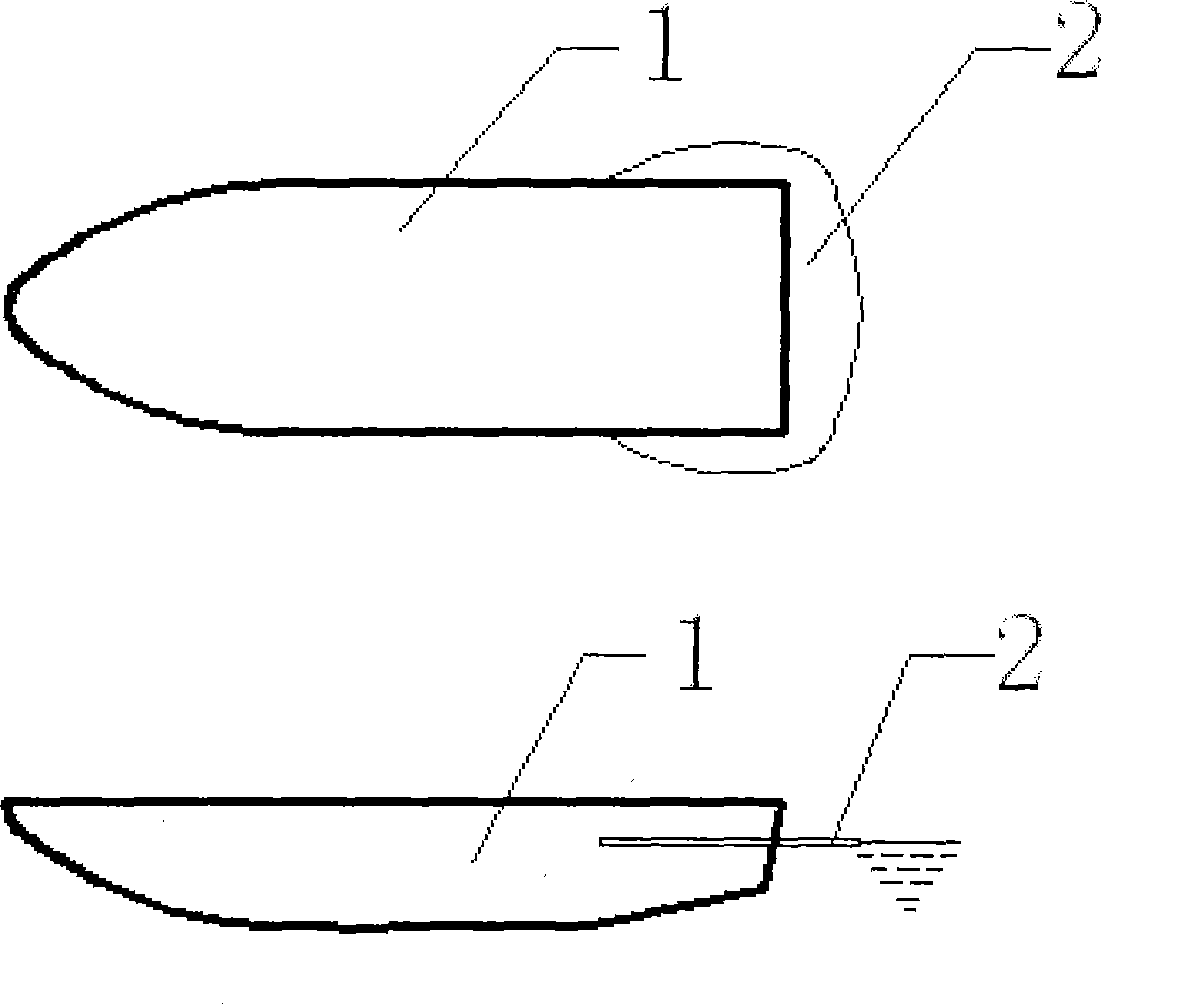

[0022] 1. Implementation plan for installation of water-air isolation belt at the stern of square stern hull

[0023] At present, most displacement high-speed ships have adopted square...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com