Rapidly mounted hinge wing for furniture

A technology of flaps and hinges, applied in the field of hinged flaps, can solve problems such as excessive size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

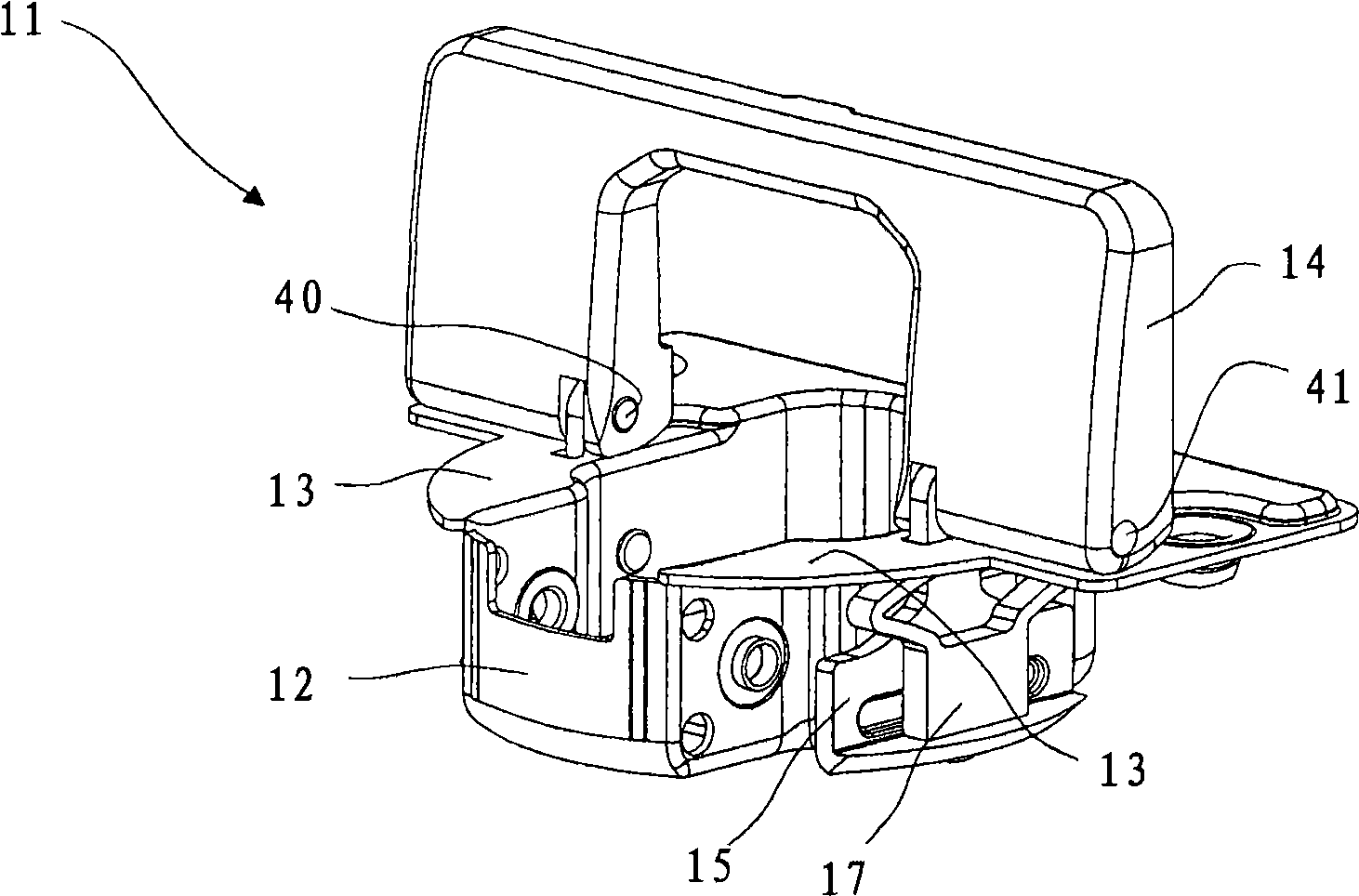

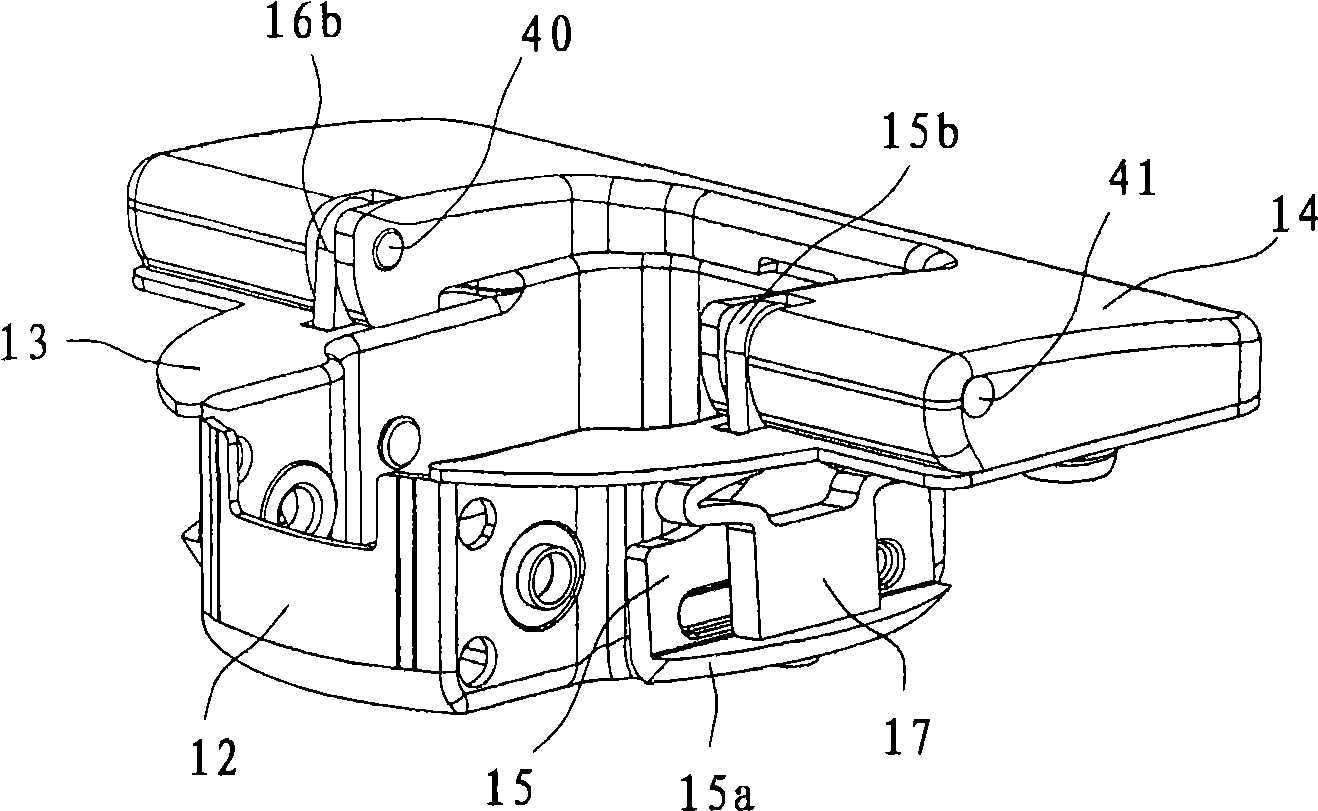

[0032] With reference to the accompanying drawings, figure 1 Hinge tabs used in hinges for connecting furniture parts are shown. The complete hinge is not shown in this figure, said hinge is easily conceivable by a person skilled in the art and may comprise a second hinge flap fixable to a second furniture part according to known teachings.

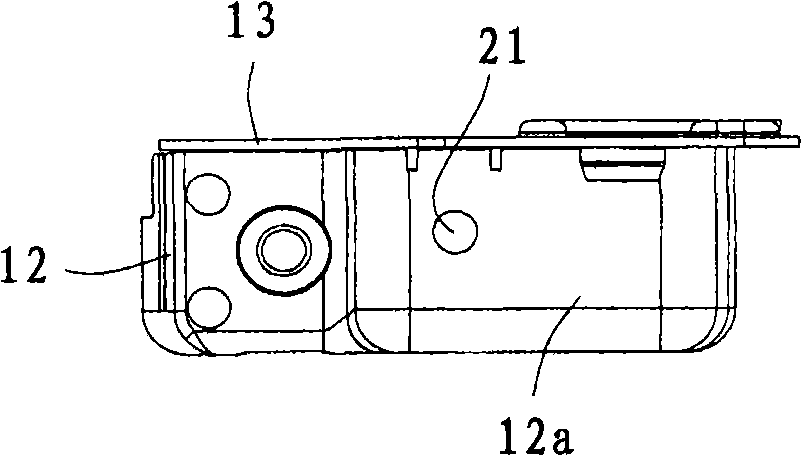

[0033] The hinge flap 11 comprises a hole 50 for insertion into a furniture part (in image 3 and 4 A cup (or box) 12 in ), the furniture part such as a flap or door.

[0034] The hinge flaps include a pair of splayable teeth 15, 16 (also in image 3 and 4 ), the pair of teeth are arranged on the exterior of the cup 12 on opposite sides of the cup.

[0035] Teeth 15 ( Figure 9 and 10 ) is generally L-shaped and includes a hook portion 15a for pressing against the side wall of the receiving hole 50 of the cup for fixing to a furniture part. The tooth also includes an upper arm 15b provided for passing through a pivot 41 ( figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com