Cooling structure for belt type stepless change

A technology of continuously variable transmission and cooling structure, which is applied in the directions of gear lubrication/cooling, belt/chain/gear, mechanical equipment, etc. It can solve the problems of complex shape of parts, adverse effects on appearance, and large number of parts, etc., and achieve improved appearance , improved appearance, and the effect of reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

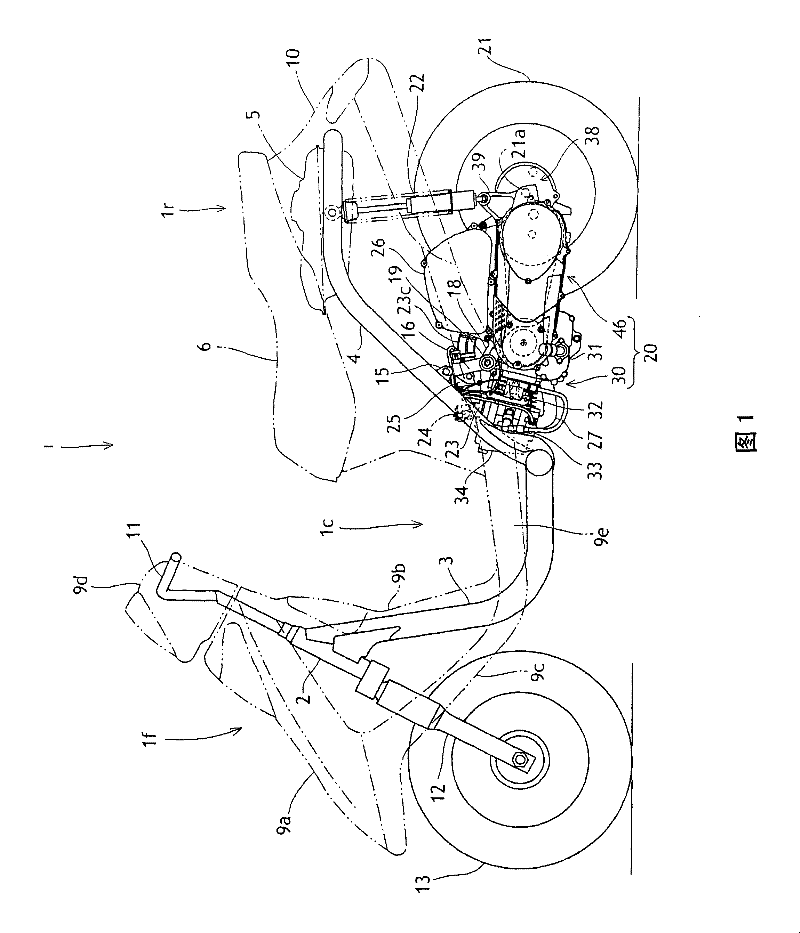

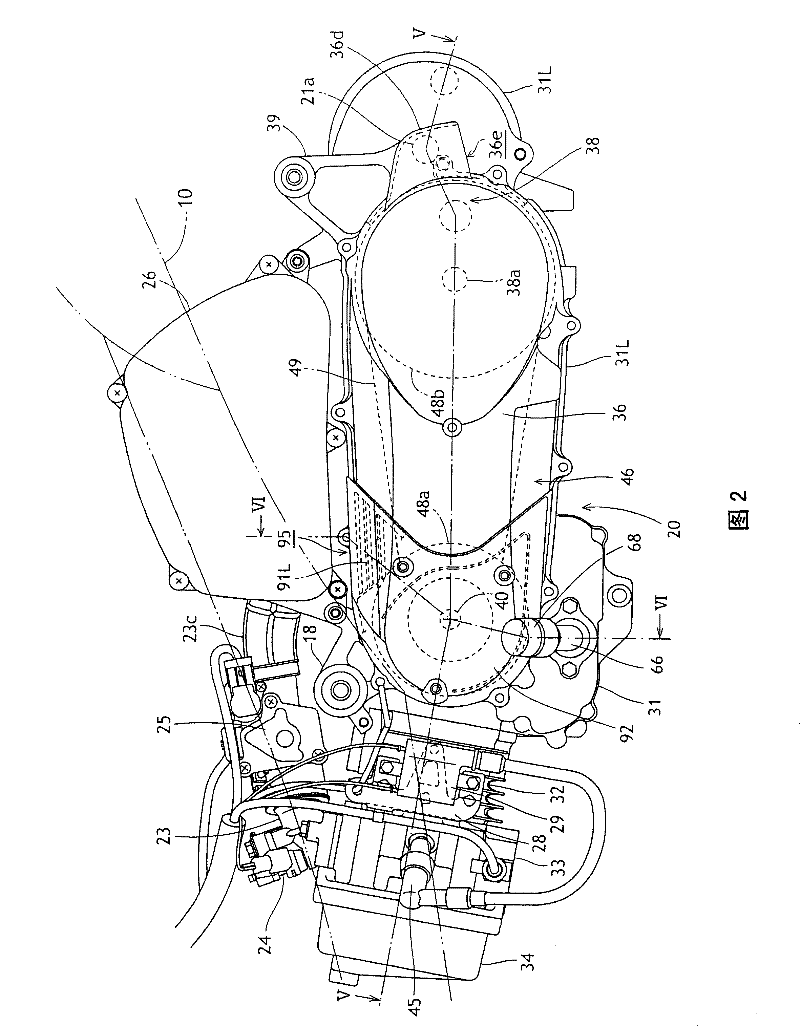

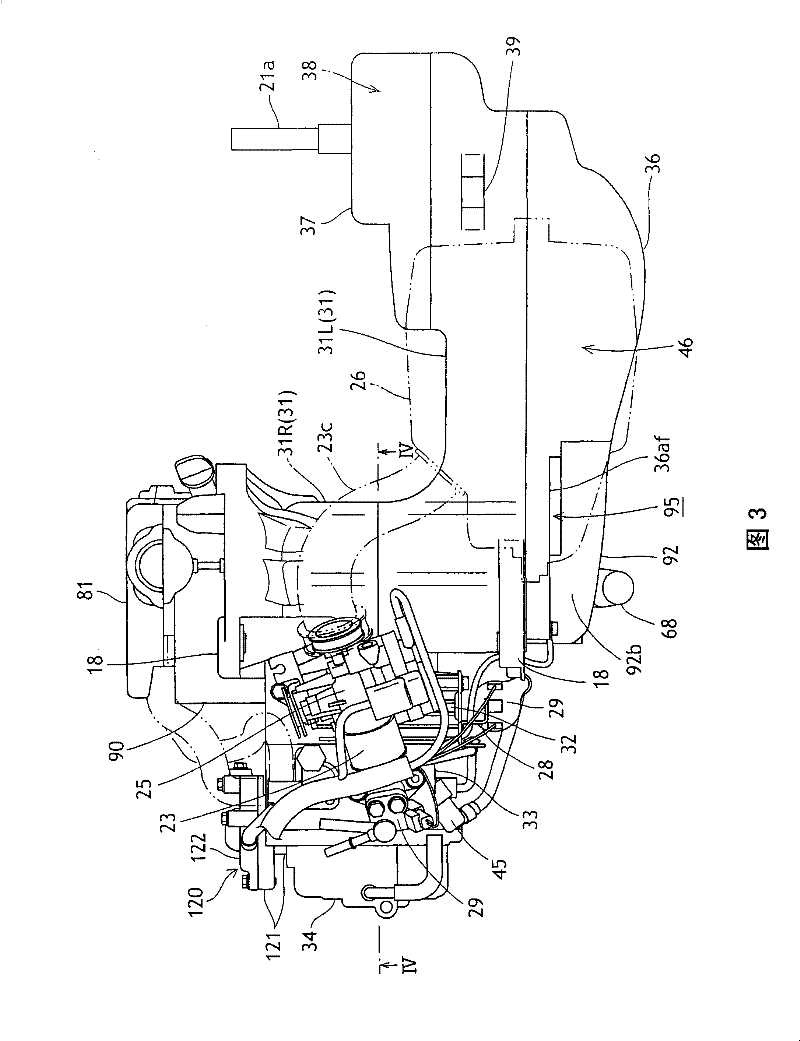

[0055] based on the following Figure 1 to Figure 11 One embodiment of the present invention will be described.

[0056] figure 1 It is a side view of the scooter-type motorcycle 1 to which the embodiment of the present invention is applied.

[0057] The front part 1f of the vehicle body and the rear part 1r of the vehicle body are connected via a low bottom part 1c, and the vehicle body frame constituting the frame of the vehicle body is roughly composed of a lower tongue 3 and a main pipe 4 .

[0058] That is, a frame lower tongue 3 extends downward from the head pipe 2 of the front portion 1f of the vehicle body. The frame lower tongue 3 is bent horizontally at the lower end, extends backward through the bottom 1c, and connects the left and right sides at the rear end. The pair of main pipes 4 rises obliquely rearward from the connecting portion, bends horizontally at a predetermined height, and extends rearward.

[0059] A fuel tank 5 and the like are supported by the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com