Single handle constant temperature constant pressure valve core

A single handle, constant temperature technology, applied in valve details, multi-port valves, valve devices, etc., can solve the problems of no pressure balance function, no insurance temperature, difficult assembly, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

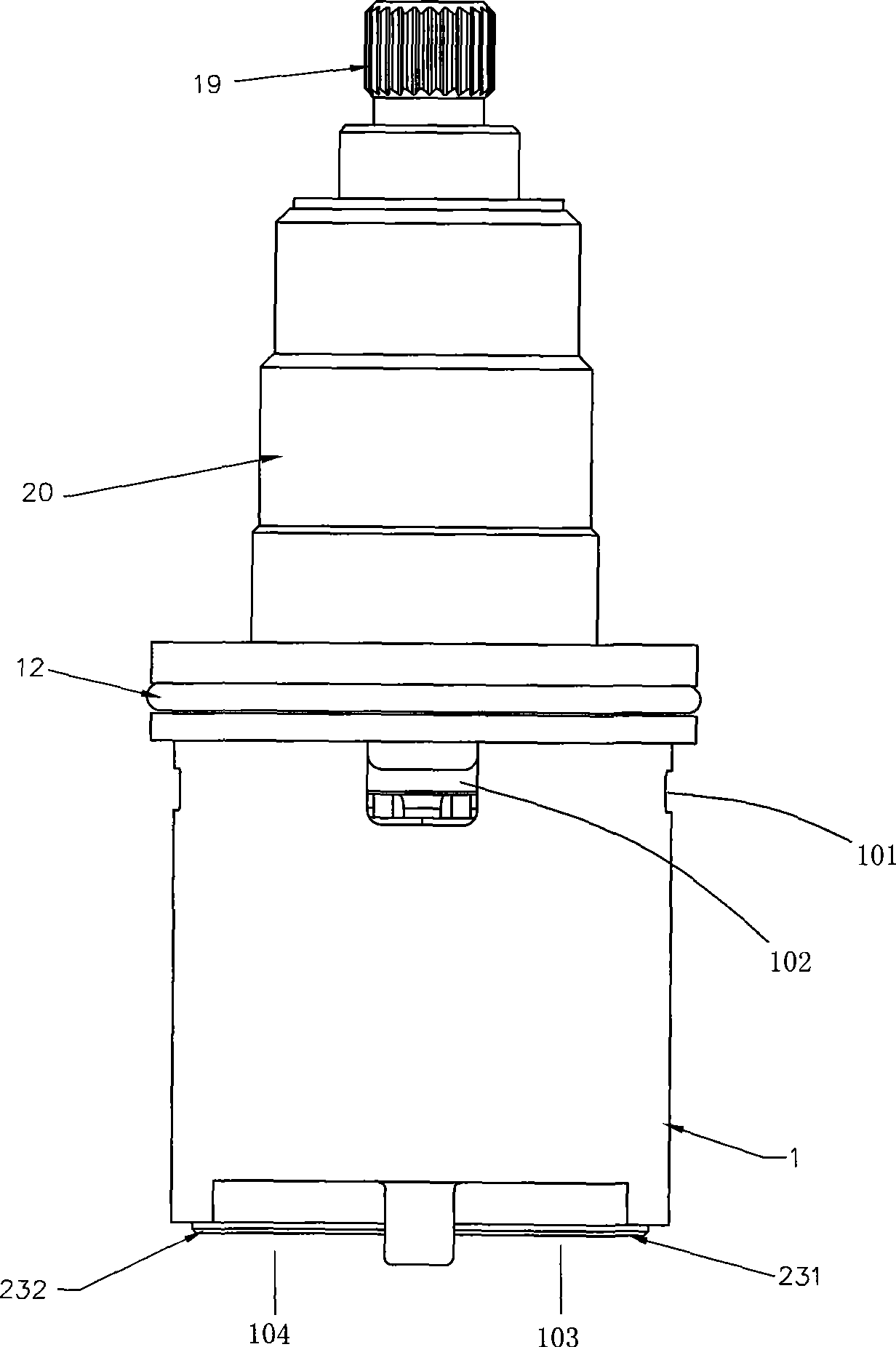

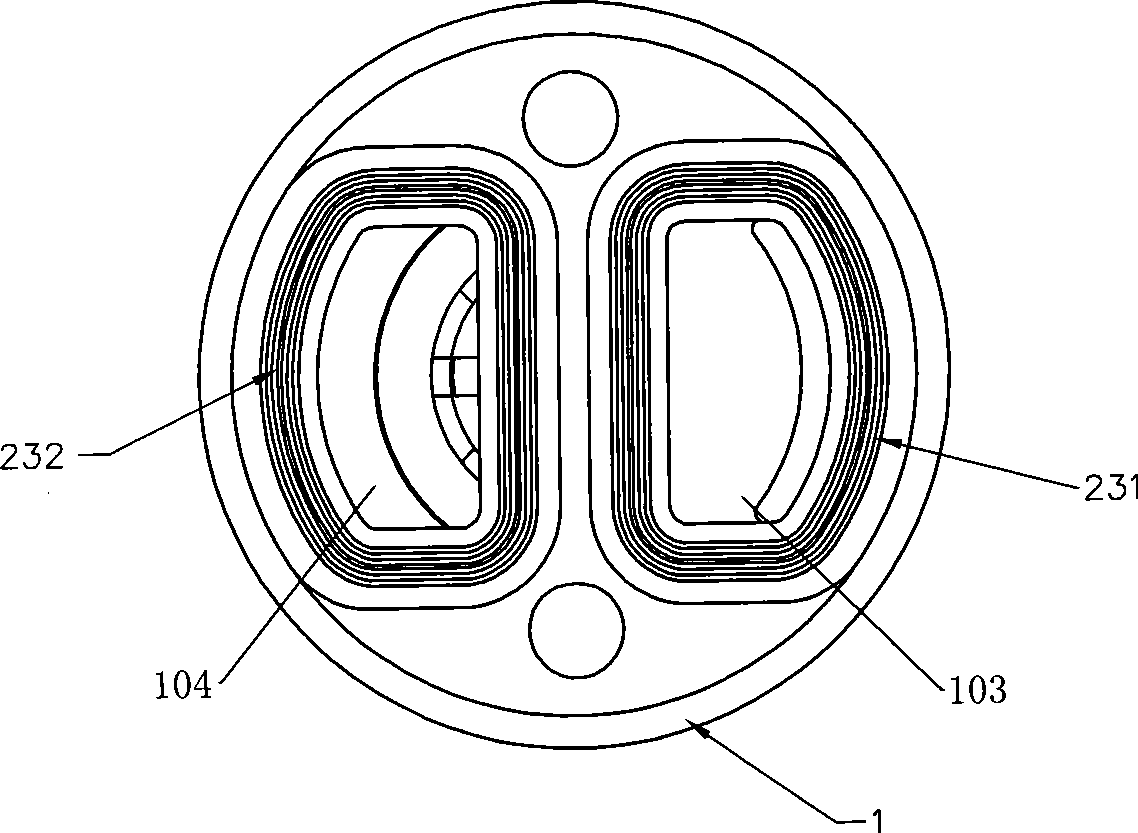

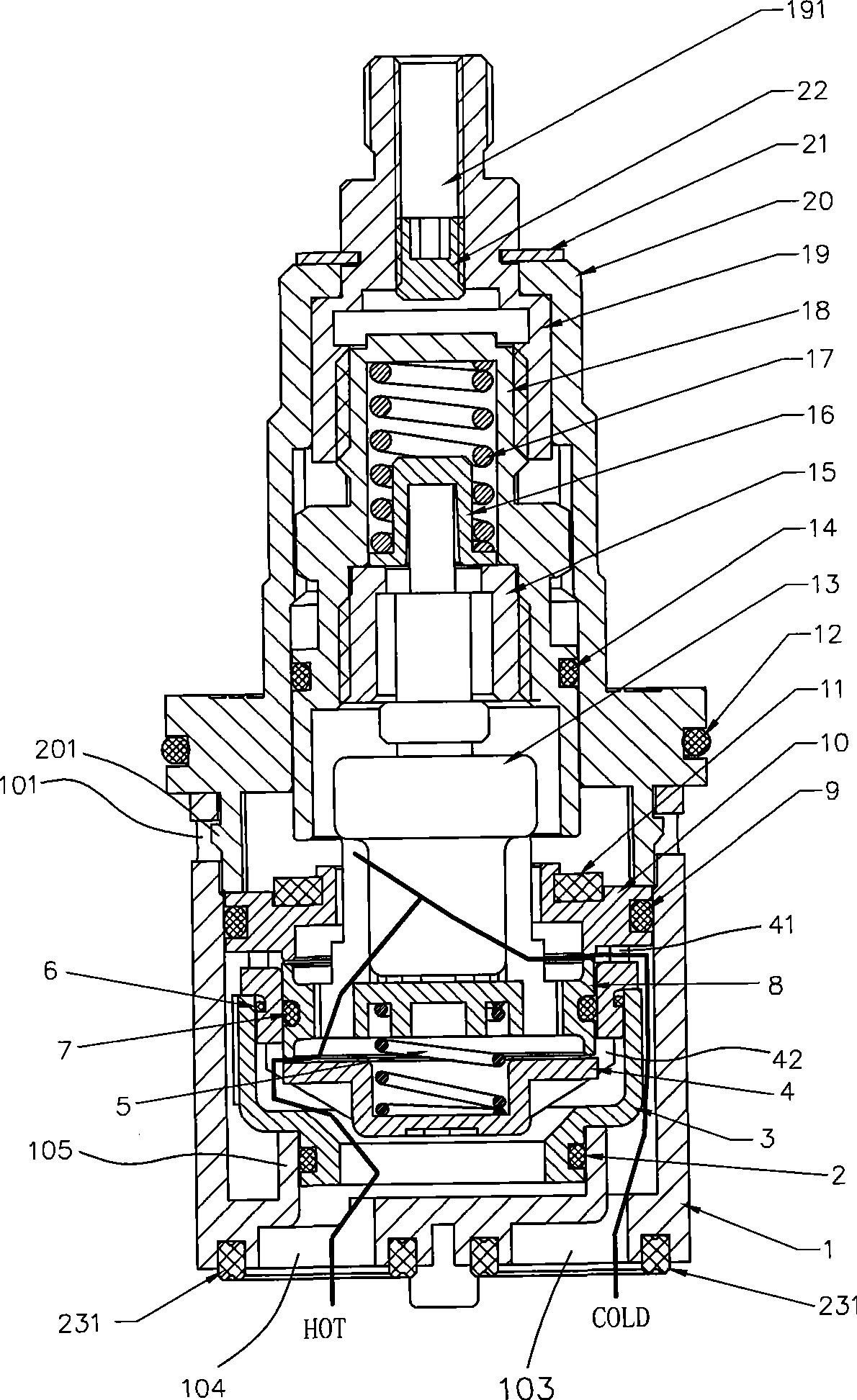

[0017] combine image 3 and Figure 4 As shown, the single-handle constant temperature and pressure balance valve core provided in this embodiment includes: the lower valve sleeve 1, the first sealing ring 2, the water-proof part 3, the water-distributing part 4, the return spring 5, the second sealing ring 6, the third Sealing ring 7, regulator 8, fourth sealing ring 9, compression seal 10, fifth sealing ring 11, sixth sealing ring 12, heat sensitive element 13, seventh sealing ring 14, set screw 15, top cap 16. Buffer spring 17, screw rod 18, valve stem 19, thermostat valve sleeve 20, collar 21, temperature limit adjustment screw 22, cold water inlet sealing ring 231 and hot water inlet sealing ring 232.

[0018] combined reference image 3 and Figure 4 , the outer edge of the thermostat valve sleeve 20 is provided with a sixth sealing ring 12 , and the lower end of the thermostat valve sleeve 20 is provided with a buckle 201 and a water outlet matching port 202 . The u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com