Injection-moulding machine with torpedo plunger plastification

A technology of injection molding machine and plunger, applied in the field of plasticizing unit, can solve the problem of inability to realize accurate measurement of plastic amount and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

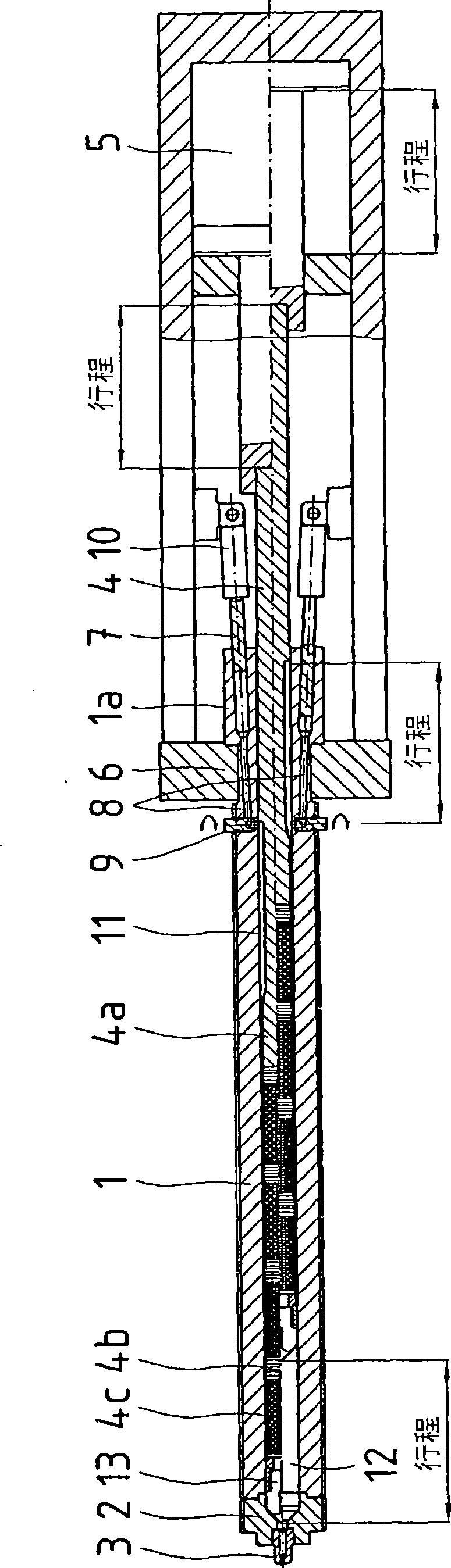

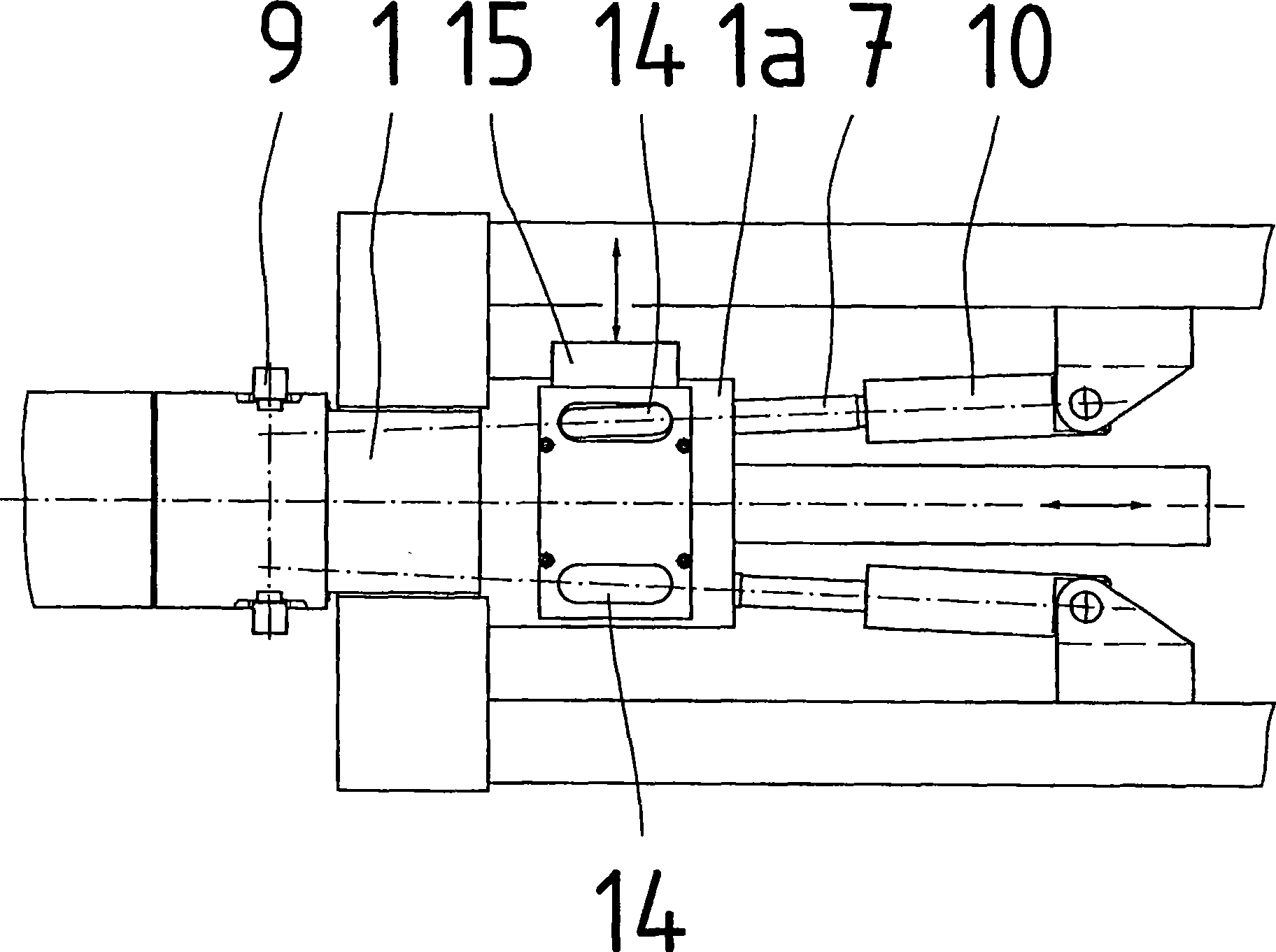

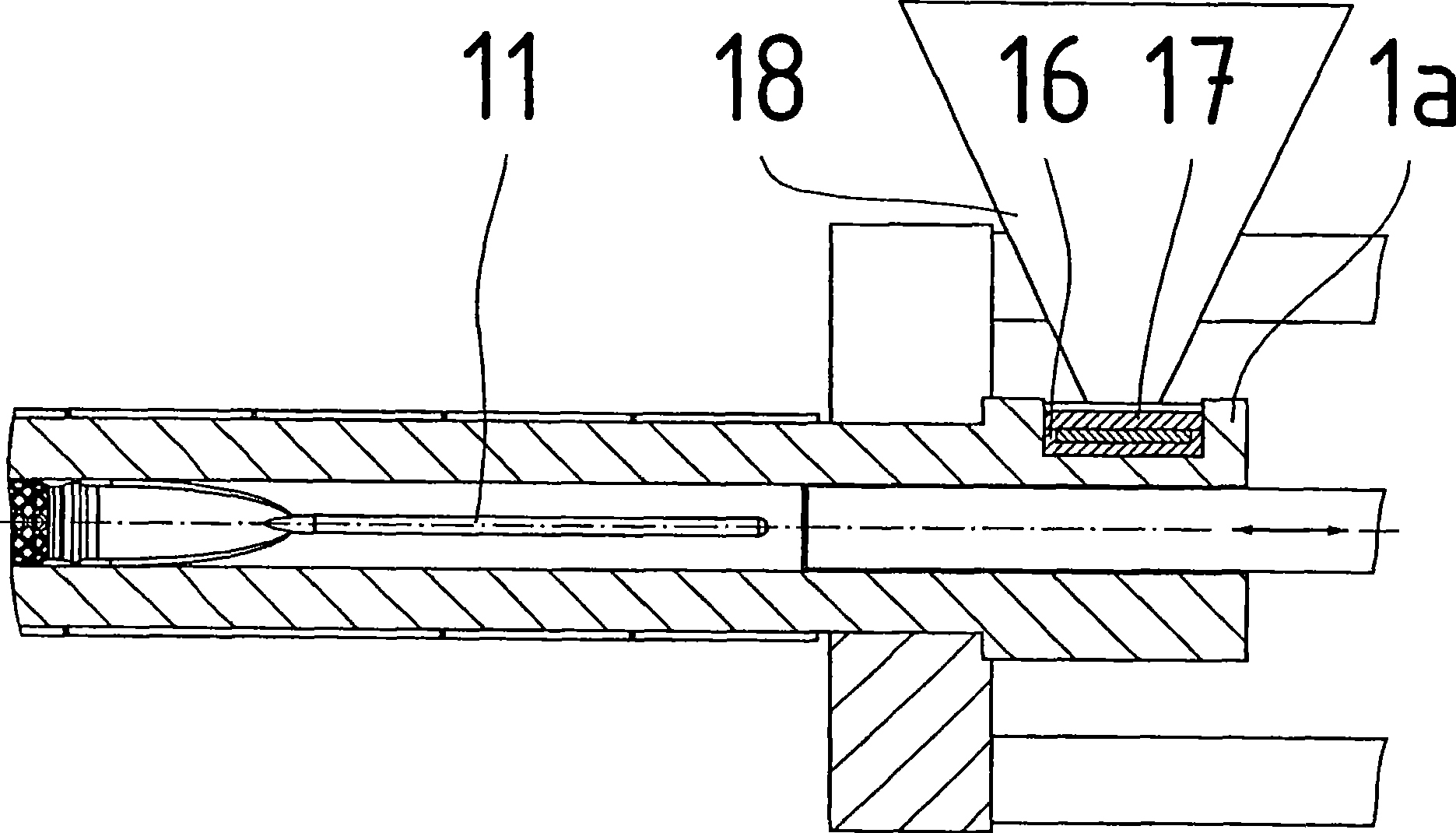

[0016] figure 1 The injection unit shown in shows a cylinder 1 with a cylinder head 2 and a nozzle 3 in which a torpedo-shaped plunger 4 connected to an injection cylinder 5 is arranged. The cylinder 1 is mounted in a housing 6 , wherein the annular surface of the cylindrically thickened cylinder end 1 a introduces the injection force into the housing 6 . In this cylinder end 1a, two smaller-diameter holes are provided on both sides next to the hole for the torpedo-shaped plunger, in which holes the filling plunger 7 is guided. These bores continue as filling channels 8 into filling channel valves 9 . What is important here is that the filling channel valve 9 alternately opens the filling channel 8 of the filling plunger 7 driven by the cylinder 10 in the direction of the nozzle, releases the connection with the filling groove 11 in the rod 4 a of the torpedo-shaped plunger 4 and Close the filling channel 8 located on the opposite side. This is a prerequisite for the situat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com