Method for producing tools especially arilling bit or milling cutter

A technology of drill bits and milling cutters, which is applied in the field of manufacturing tools and can solve problems such as drill bit manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] FIG. 1 shows a side view of a cut blank 1 . The blank along the length L R have a consistent diameter D R .

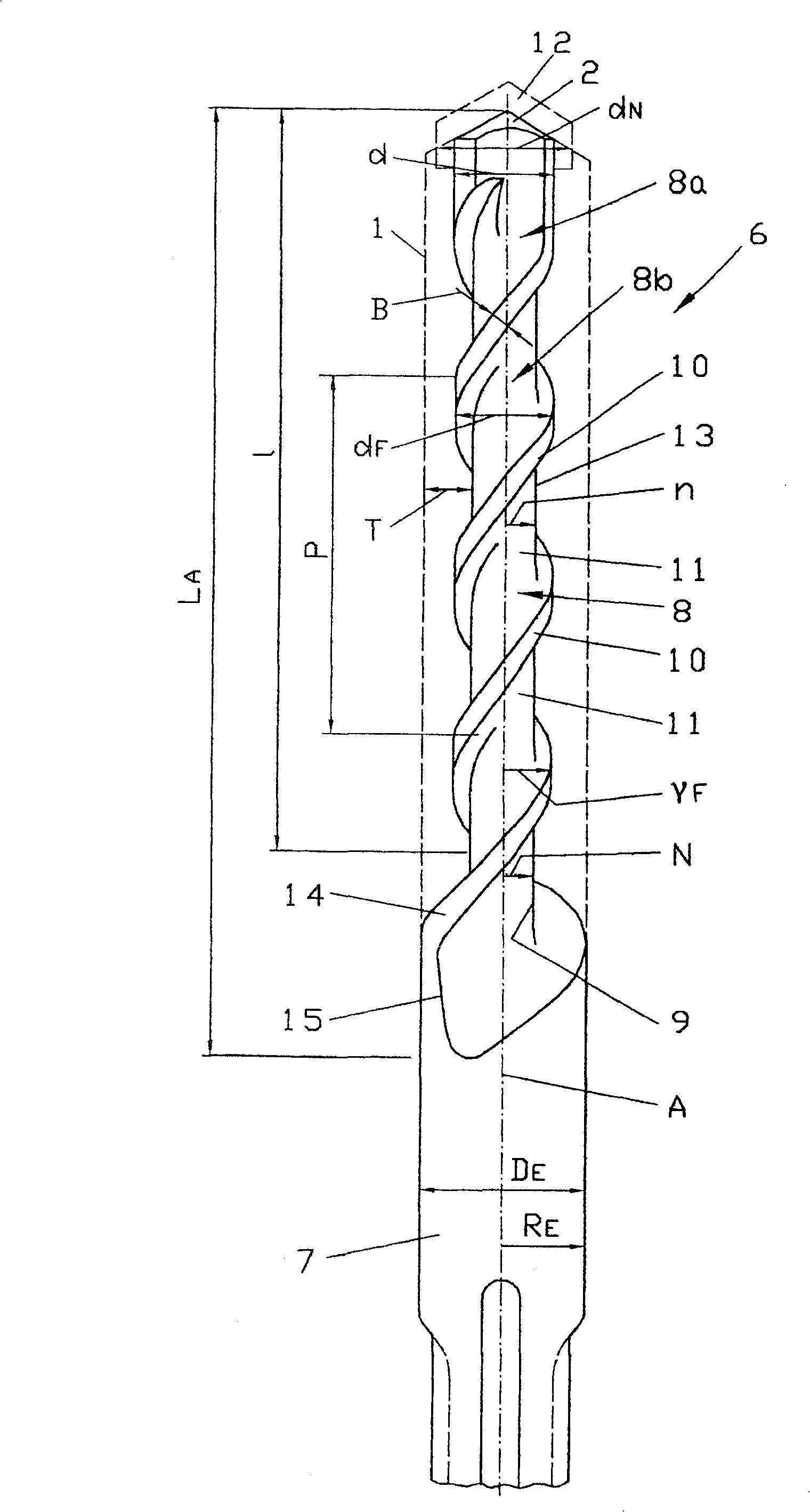

[0044] FIG. 2 shows the blank shown in FIG. 1 which has been machined at its end, ie has been machined to form the tip 2 and the opposite end 3 . The tip 2 is configured as a cone 4 and the end 3 is provided with a chamfer 5 .

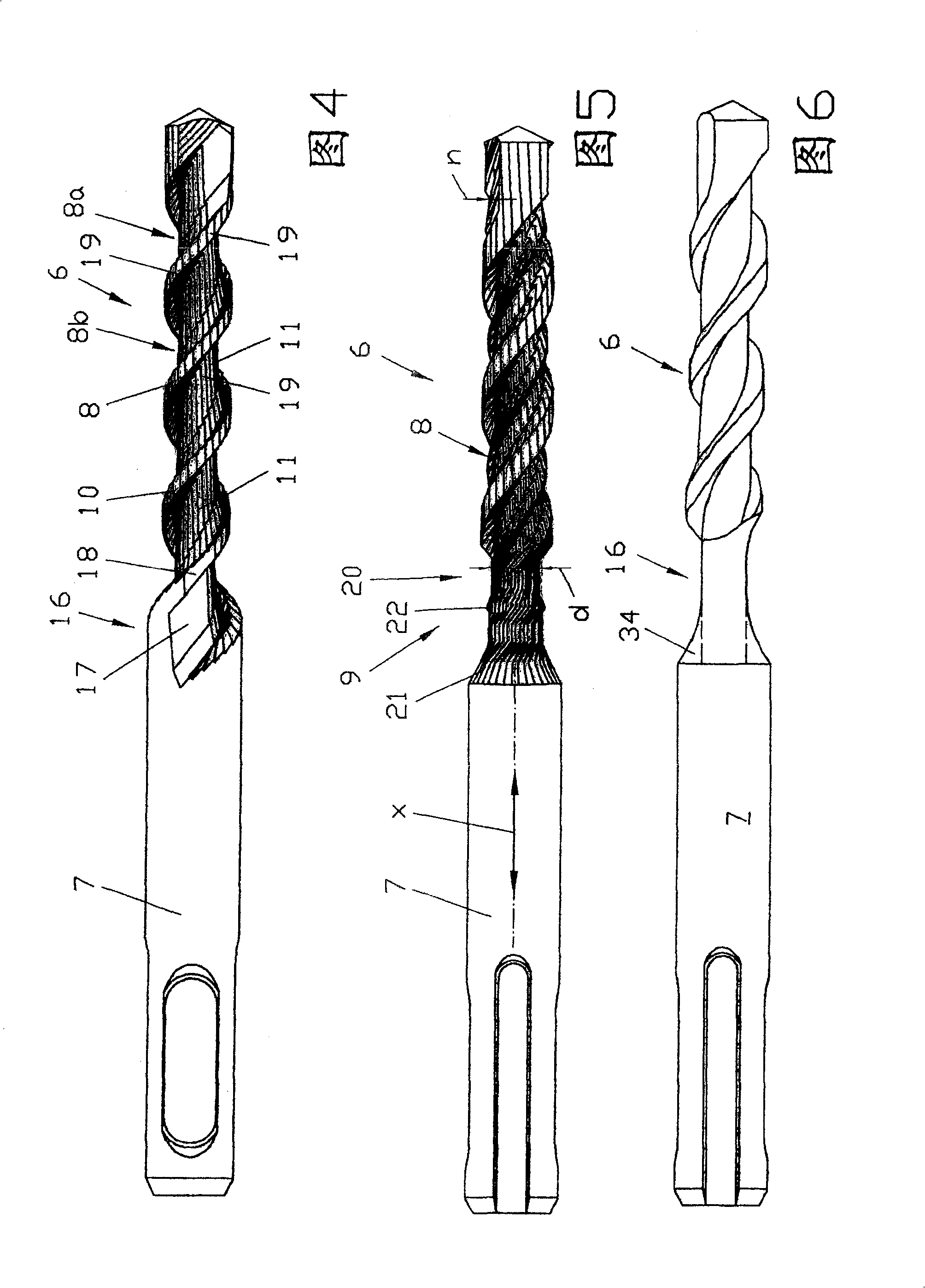

[0045] image 3 A first variant of a drill bit 6 is shown, which is produced from a blank 1 by the method according to the invention. The drill bit 6 includes a clamping shank 7 which is only partially shown with its part facing the helical part 8 . The clamping part, only partially shown, located opposite the screw part 8 is designed as an SDS-PLUS handle 33 (DE3716915A1). Alternatively, other standard shank configurations, such as SDS-MAX shank (DE2551125C2), can also be provided, or the original cross-section can be kept unchanged, such as cylindrical for fixing in the chuck.

[0046] The screw part 8 includes a screw outlet 9 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com