Bottle container

A container and container body technology, applied in the field of bottle containers, can solve problems such as residue, sealing material falling, and no special action, etc., to achieve the effect of improving the certainty and reducing the force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

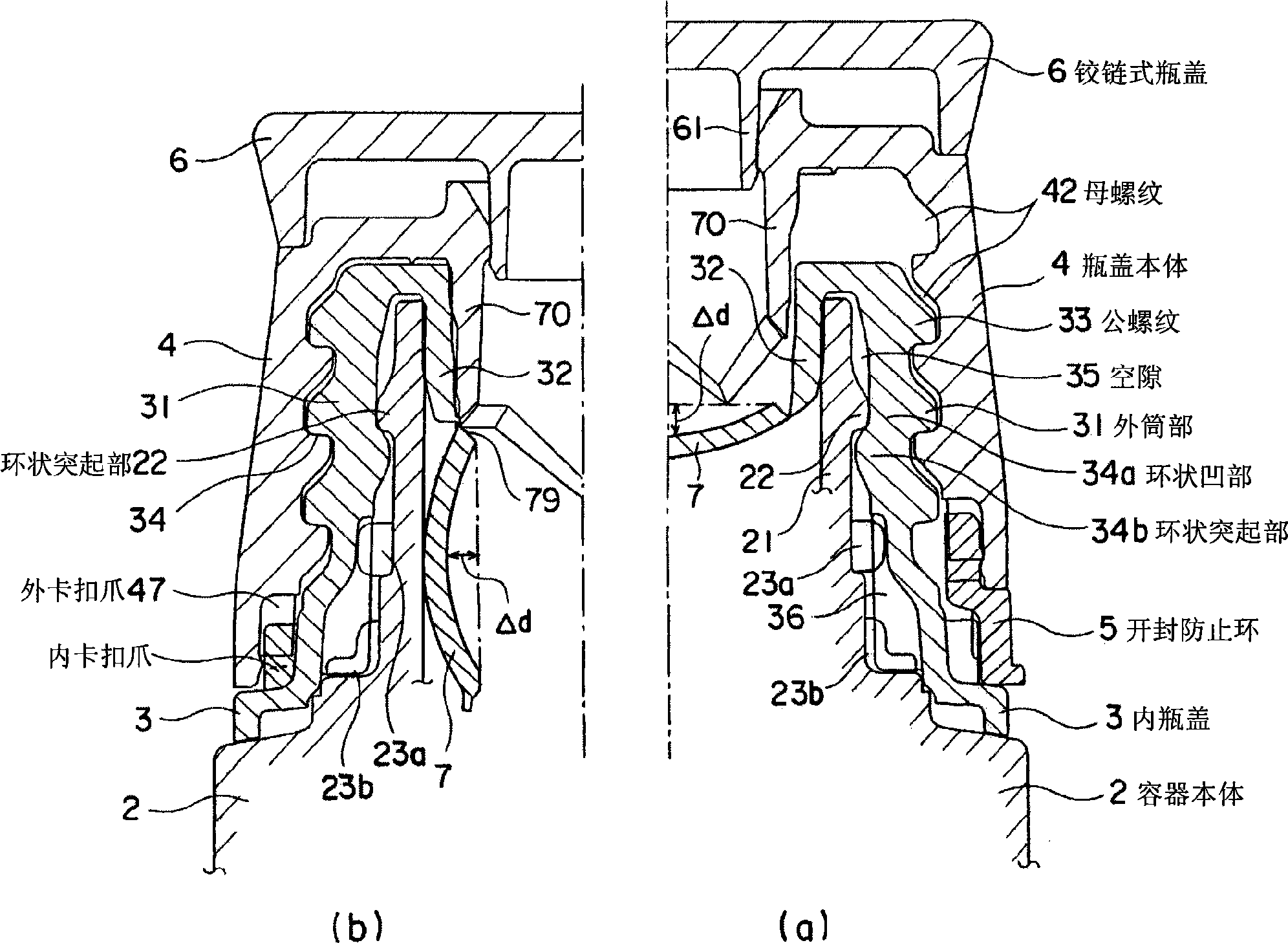

[0145] figure 1 It is a partial enlarged view showing the bottle cap of Example 1 of the present invention installed in the container body, (a) is the unused state, and (b) is the state of the unsealed sealing film.

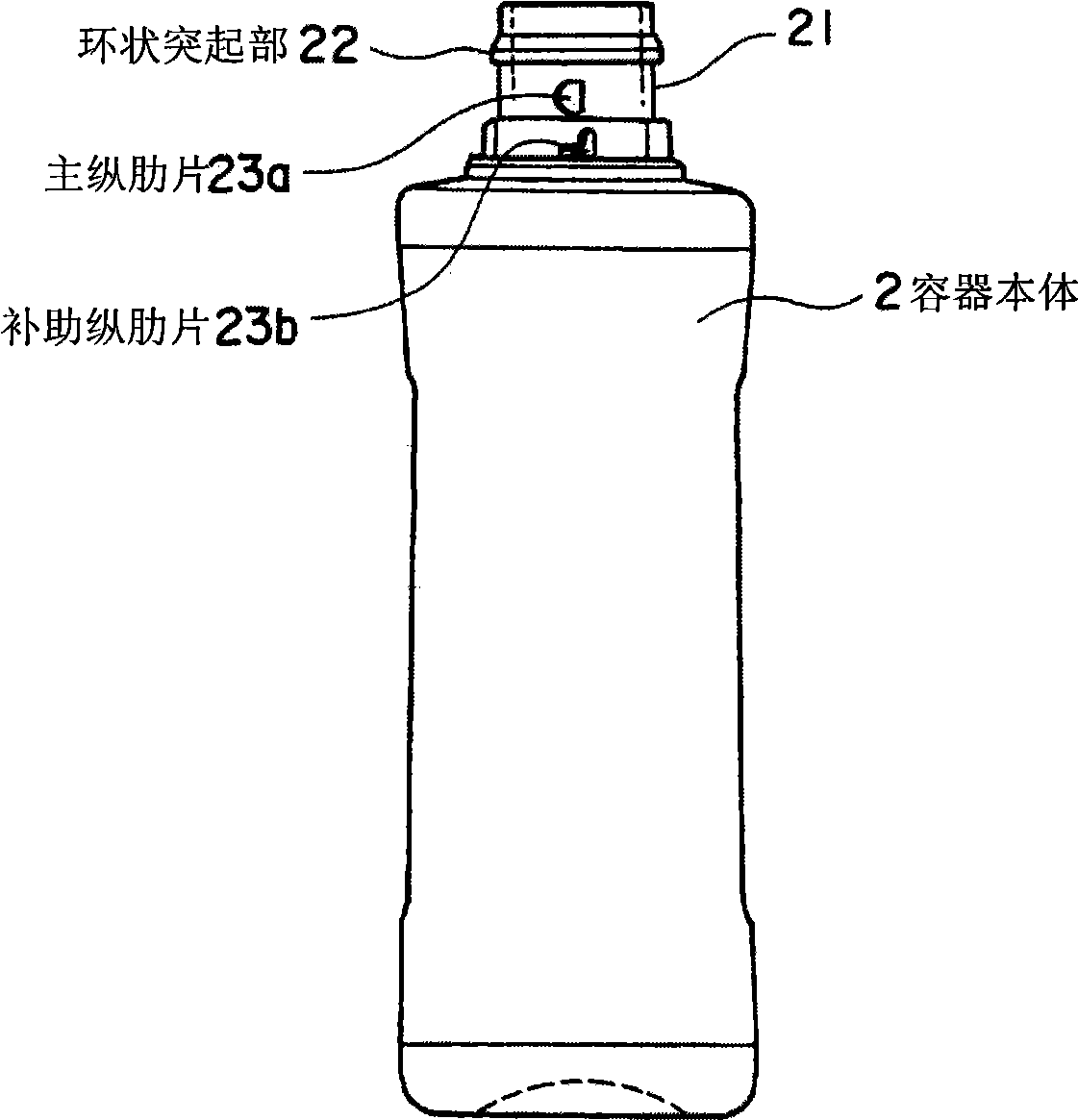

[0146] figure 2 It is an external view showing the container body.

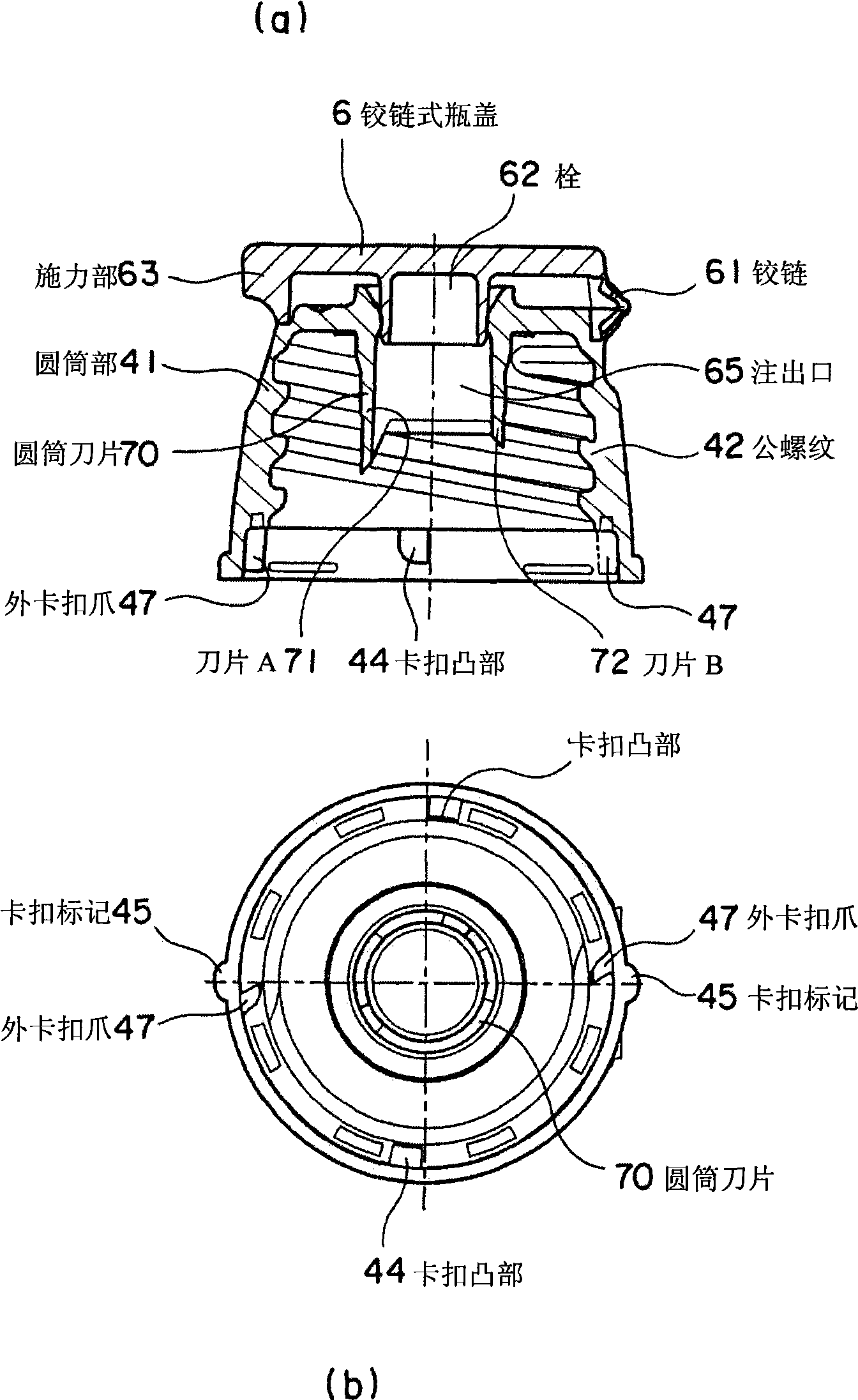

[0147] image 3 (a) is a sectional view of the bottle cap body with a hinge, (b) is a bottom view, Figure 4 (a) is an external view of the hinged cap body, and (b) is a cross-sectional view of the hinged cap body in an open state.

[0148] Figure 5 (a) is a plan view, (b) is a sectional view, (c) is a bottom view, and (d) is an external view of the inner bottle cap.

[0149] Figure 6 It is a schematic diagram showing a part of the broken surface of the anti-opening ring.

[0150] Figure 7 It is a schematic diagram of the buckle relationship of the present invention, (a) is a diagram of the completion of the buckle installation, and (b) is a state where the bottle cap body is halfwa...

Embodiment 2

[0201] Please refer to Figure 11 , Figure 12 Example 2 will be described. Parts not mentioned are in principle common to Embodiment 1.

[0202] Figure 11 It is a partial enlarged view showing the state of the bottle cap of Example 2 mounted on the container body. (a) shows the unused state, and (b) shows the state of the unsealed film. Figure 12 yes Figure 11 A cross-sectional view of each component is shown. (a) is a sectional view of the container neck, (b) is a sectional view of the inner cap, (c) is a sectional view of the cap body, and the right half (c1) shows the state where the anti-opening ring is inserted.

[0203] The biggest difference between embodiment 2 and embodiment 1 is that the upper side of the annular recess 34a of the inner bottle cap is also provided with an upper annular protrusion 34c as an annular protrusion, forming a container body together with the annular recess 34a The ring-shaped protruding portion 22 snap-fit structure provided on...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap