Efficient process for purification of high molecular weight hyaluronic acid

A technology of hyaluronic acid and molecular weight, applied in the effective field for purifying high-molecular-weight hyaluronic acid, can solve problems such as environmental hazards, and achieve the effect of saving cost and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0115] Example 1: Bacterial strains and media. S. equi subsp. zooepidemic ATCC 39920 was obtained from the American Type Culture Collection. Bacteria were maintained on brain heart infusion agar or tryptone soy broth.

Embodiment 2

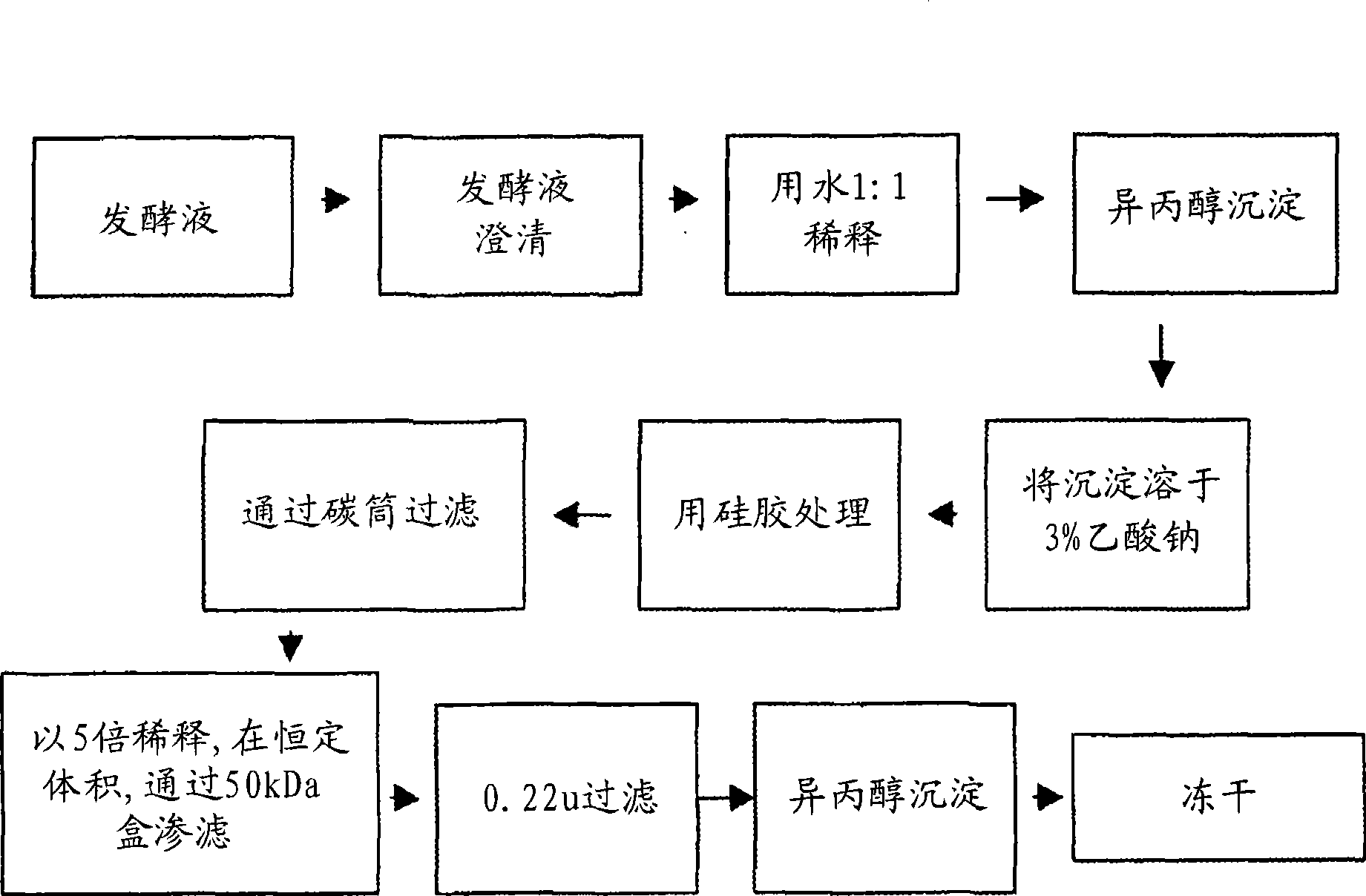

[0116] Example 2: Estimation of HA

[0117] After precipitation with an equal volume of isopropanol and redissolution in 3% sodium acetate solution, it was determined by carbazole (Bitter, T., and Muir, M., A modified uronic acid carbazole reaction. Anal Biochem 4: 330-334, 1962 ) routinely estimates HA in fermentation broth.

Embodiment 3

[0118] Embodiment 3: Culture medium optimization

[0119] For the medium optimization experiment, after 2.5% casein hydrolyzate enzyme, 1% yeast extract, 0.2% K 2 HPO 4 , 0.15% NaCl, 0.04% MgSO 4 ·7H 2 Streptococcus zooepidemicus was cultured in a medium consisting of O and 2% carbon source (sucrose). The organisms were grown in Erlenmeyer flasks at 37°C for 24 hours at 200 rpm. To evaluate the effect of metal ions on HA production, at a final concentration of 0.025%, filter-sterilized CuSO 4 , ZnSO 4 and MnSO 4 The solution was added to the medium. see Figure 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com