Control method

A wind wheel and generator technology, applied in engine control, engine control parameters, wind engine control, etc., can solve the problems of overrunning of bearing balls, high time and cost, and reduced lubrication, etc., to achieve time period extension, Effect of low cost and loss reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

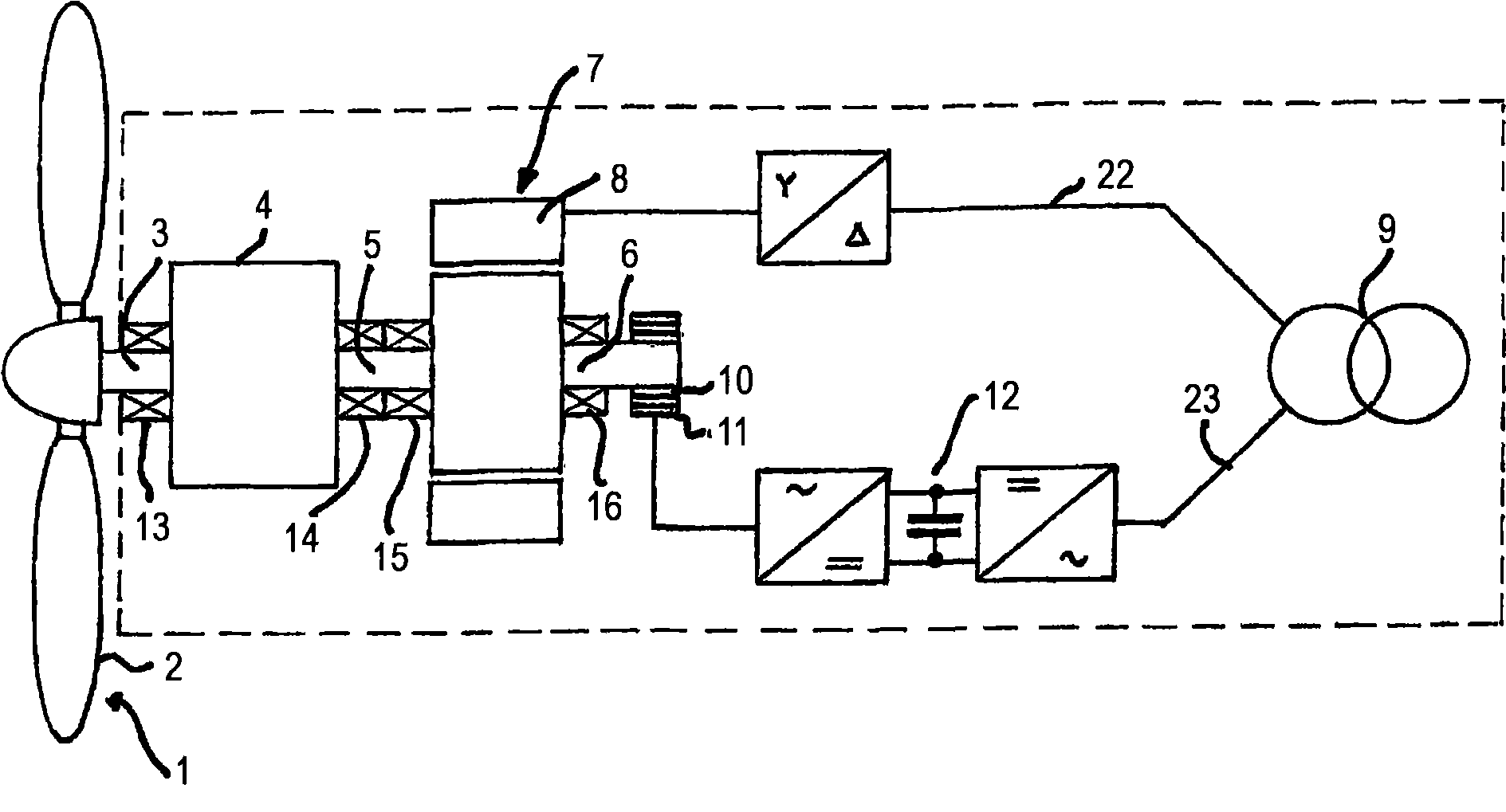

[0024] figure 1 The general structure of a wind turbine, known as a wind turbine with a double-fed induction generator (DFIG), is illustrated very schematically. The components of the wind turbine within the dashed box are usually arranged in a so-called nacelle or casing, which is arranged on the column of the wind power plant. The wind turbine has a propeller 1 with blades 2 arranged to capture the wind and drive a rotor 3 in rotation. For wind turbines rated at 3MW and 2MW, the rotor typically has rotational speeds of 3-15 rpm and 5-20 rpm, respectively. The rotor 3 is connected to a gearbox 4, which normally increases the rotational speed on its output shaft 5 to 100 times the rotational speed of the rotor 3 for higher ratings, and makes it output for lower ratings The rotational speed on the shaft 5 is increased to 60 times the rotational speed of the rotor 3 . The output shaft 5 is connected to or carries the rotor 6 of an asynchronous generator 7 having stator windin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com