Transmission apparatus and computer program

A technology of transmission device and transmission volume, which is applied in the direction of measuring device, transportation packaging, transportation and packaging, etc., which can solve the problems of inability to eliminate transmission offset, calculation of correction amount, uneven transmission volume, etc., so as to suppress measurement errors and suppress Influence of measurement error, effect of high transmission accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

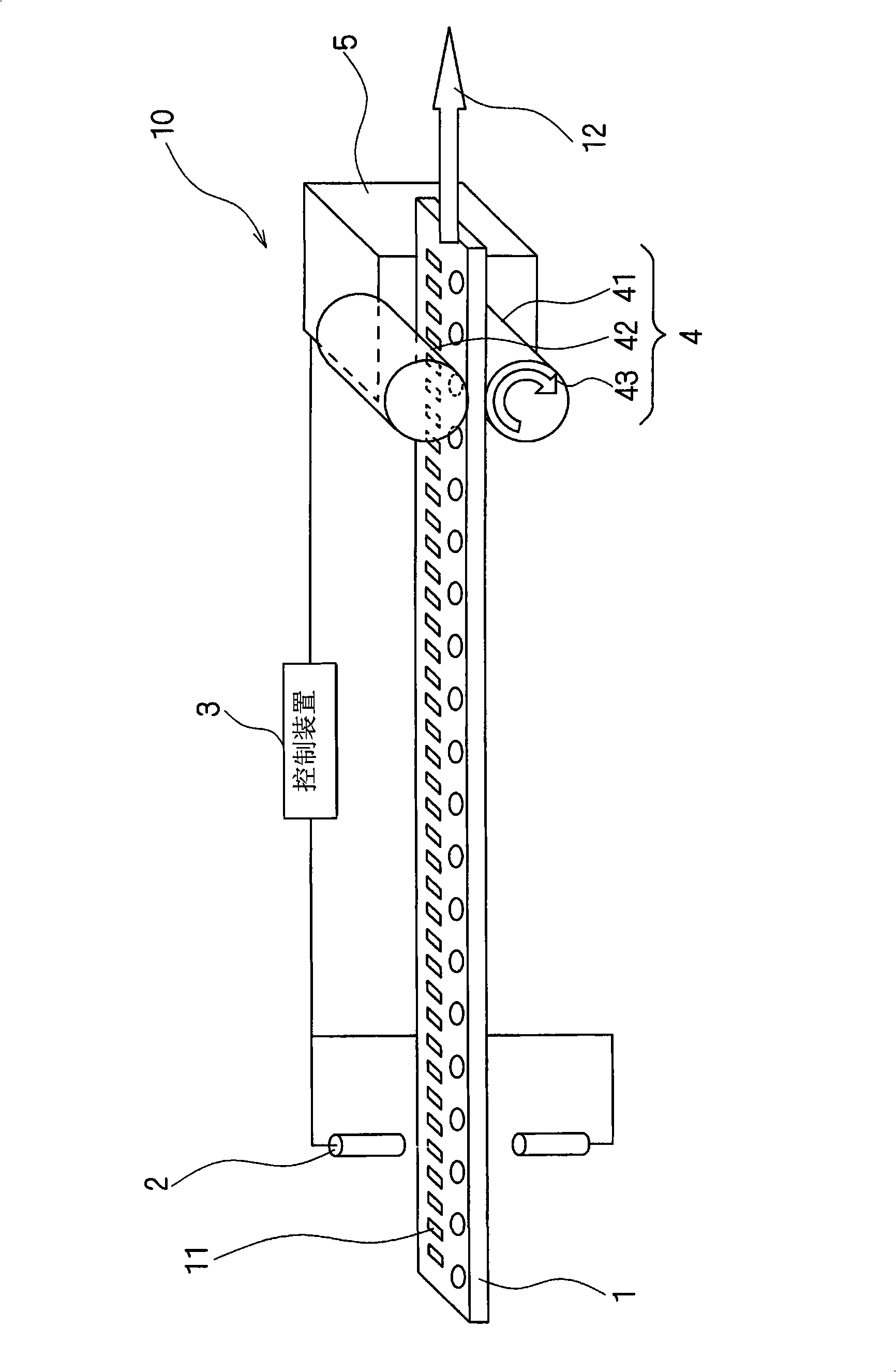

[0060] figure 1 It is a perspective view schematically showing the configuration of the transmission device according to Embodiment 1 of the present invention. Such as figure 1 As shown, the conveying device 10 related to the first embodiment can use the conveying roller 4 to convey the belt-shaped continuum, that is, the conveyer belt 1. On the belt-shaped continuum, recesses 11, 11, ... are formed at substantially equal intervals for As a mark when delivering electronic parts.

[0061] The conveyance roller 4 is composed of a feed roller 41 connected to a drive source 5 such as a motor, and a pressure roller 42 that pinches the conveyance belt 1 . The conveyor belt 1 is pinched between the feed roller 41 and the pressure roller 42 , and the feed roller 41 rotates in the direction indicated by the arrow 43 to transport the conveyor belt 1 in the direction indicated by the arrow 12 .

[0062] exist figure 1 Near the center of the conveyor belt 1, the electronic components ...

Embodiment approach 2

[0089] Since the configuration of the transmission device 10 according to the second embodiment of the present invention is the same as that of the first embodiment, the same reference numerals are assigned to the same components and their descriptions are omitted. The second embodiment differs from the first embodiment in that the rotary encoder 20 for detecting the rotation angle of the conveyance roller 4 is provided, and the feed amount is corrected using the stop position estimated from the rotation angle of the drive source 5 .

[0090] Figure 8 It is a perspective view schematically showing the configuration of the transmission device according to Embodiment 2 of the present invention. Such as Figure 8 As shown, the conveying device 10 related to the second embodiment can convey the conveying belt 1 on the conveying roller 4, and recesses 11, 11, ... are formed on the conveying belt 1 at approximately equal intervals, which are used as marks when conveying electronic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com