Low-temperature matching co-firing method of ferrite and ceramic material

A technology of ceramic materials and ferrites, which is used in the field of low-temperature co-firing of ceramics and ferrites, and matching co-firing of heterogeneous materials. problem, to achieve the effect of improving low-temperature sintering densification characteristic parameters, reliability assurance, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

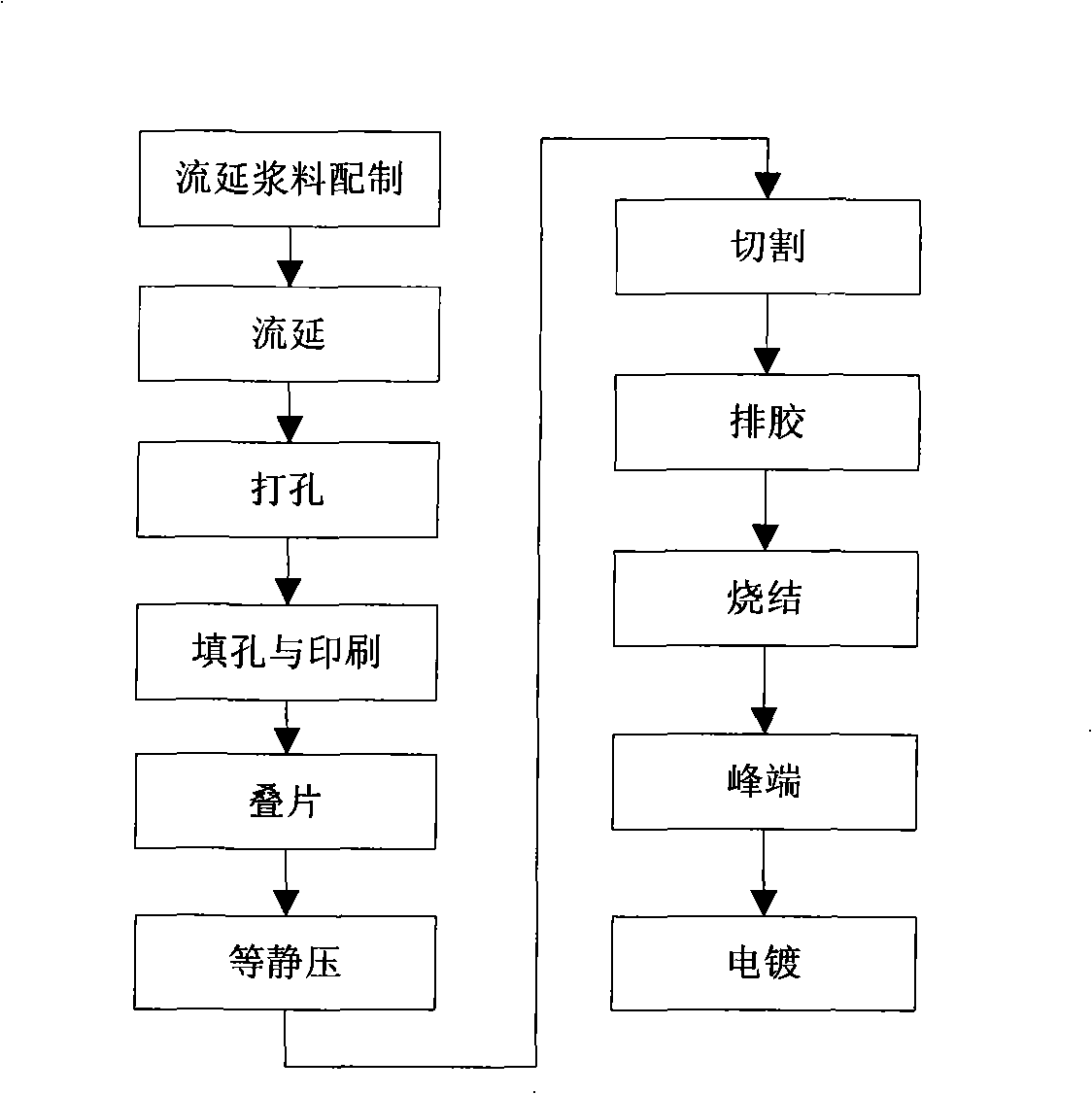

Method used

Image

Examples

Embodiment Construction

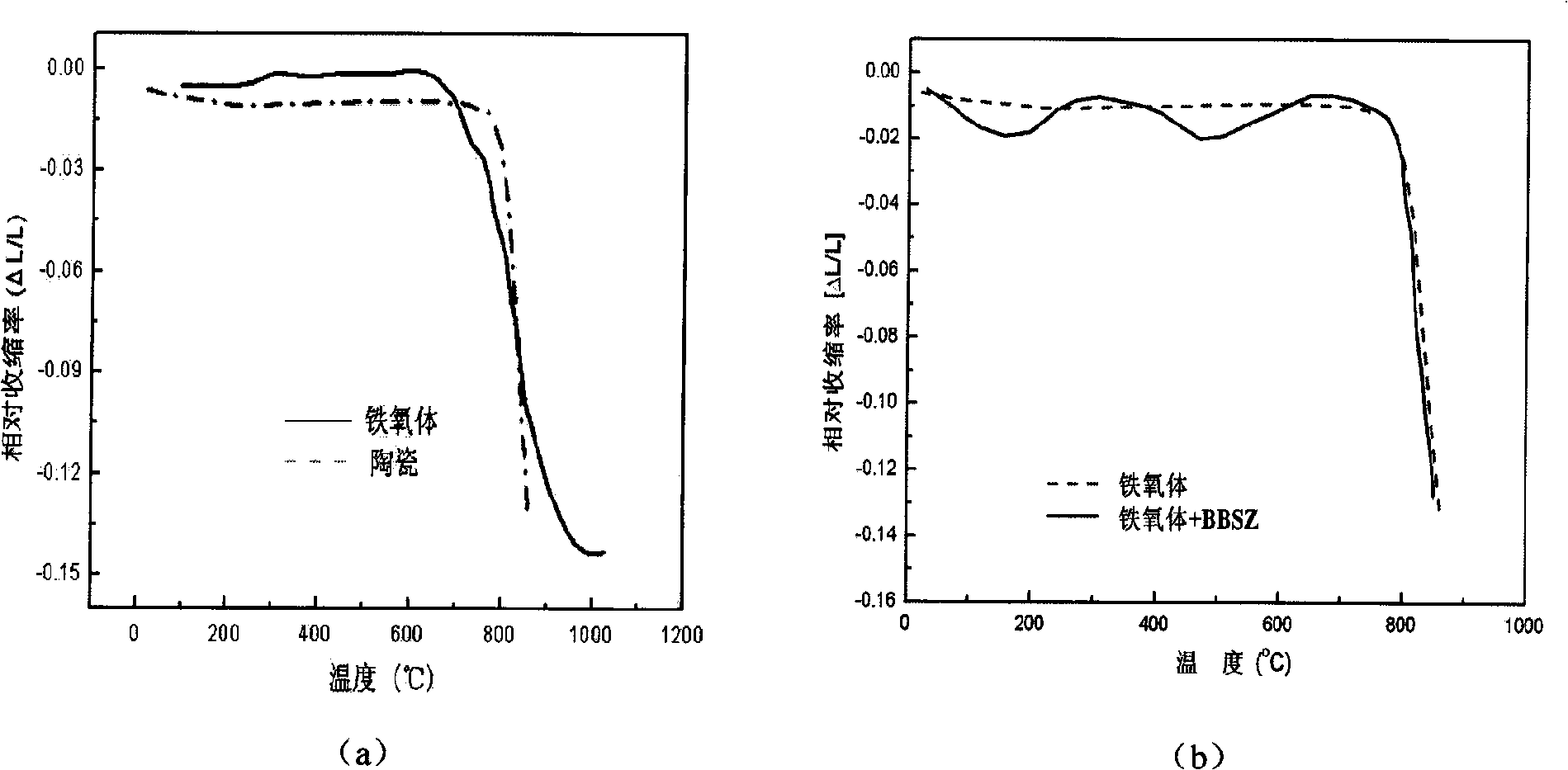

[0014] Weigh 100.0g NiCuZn ferrite powder (self-made), solvent toluene 30.0g, ethanol 20.0g, dispersant 5.5g, plasticizer 0.7g, ball mill for 5 hours, add 33.0g of binder, ball mill for 8 hours, add 5wt% The BBSZ is matched with sintering aids, ball milled for 12 hours, after defoaming, cast, the film thickness is 25um, and it is ready for use.

[0015] Weigh 100.0g of ceramic powder (trade name: ULF140, purchased from Ferro, USA), solvent toluene 30.0g, ethanol 20.0g, dispersant 5.5g, ball mill for 5 hours, add 33.0g of binder, ball mill for 8 hours, after defoaming , casting, film thickness 25um, ready to use.

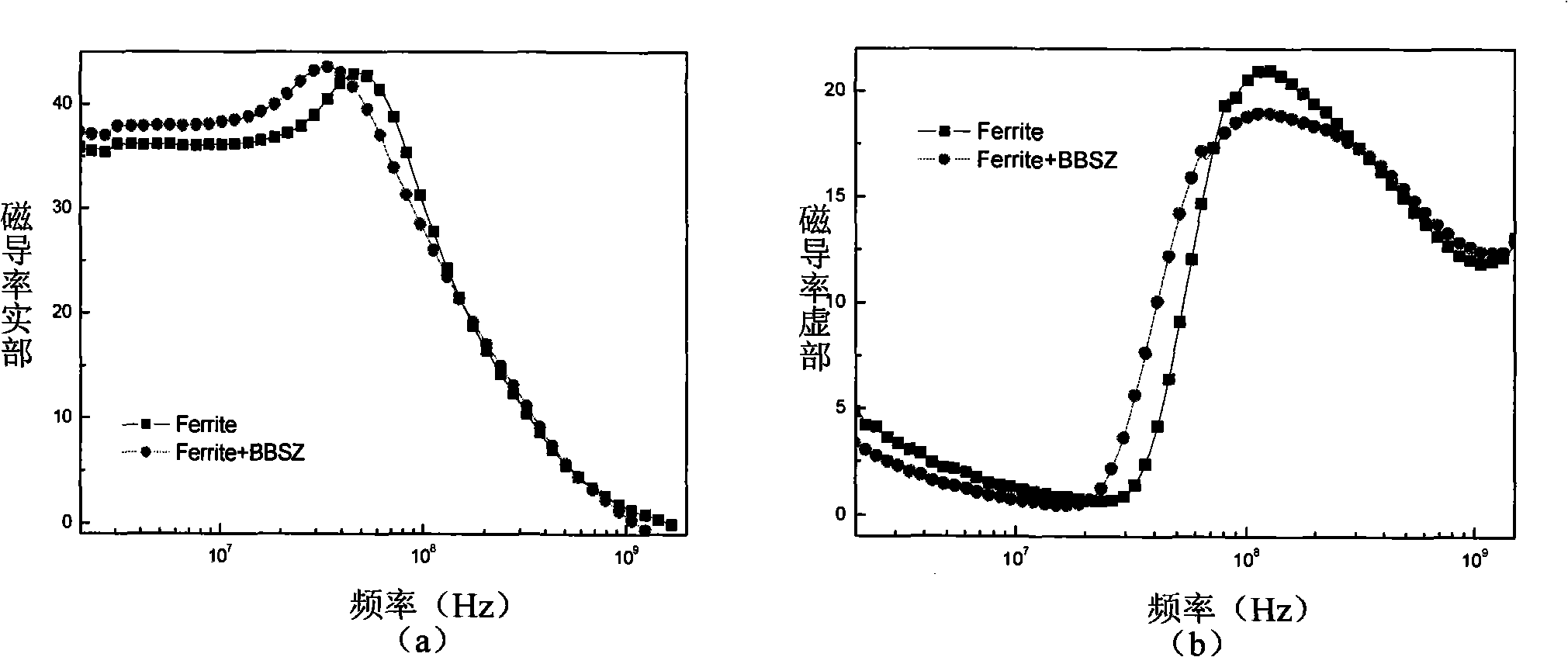

[0016] After debinding (400°C, 8h) to the ferrite slurry prepared in the above embodiment, ferrite powder containing 5wt% BBSZ was obtained. After granulation, pressing the standard ring, and sintering at 900°C for 6 hours, it was tested with Agilent4291B, and the results are shown in figure 2 . figure 2 (a) and (b) are the test data of real part and imaginary p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com