Line-type heat detector based on thermoelectric couple principle

The principle of a thermocouple and the technology of fire detectors are applied in the direction of electric fire alarms, thermometers and instruments using electric/magnetic components directly sensitive to heat, etc., which can solve the problem of inability to monitor the open circuit of linear temperature-sensing fire detectors. Or open circuit fault, unreliable alarm, smaller and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

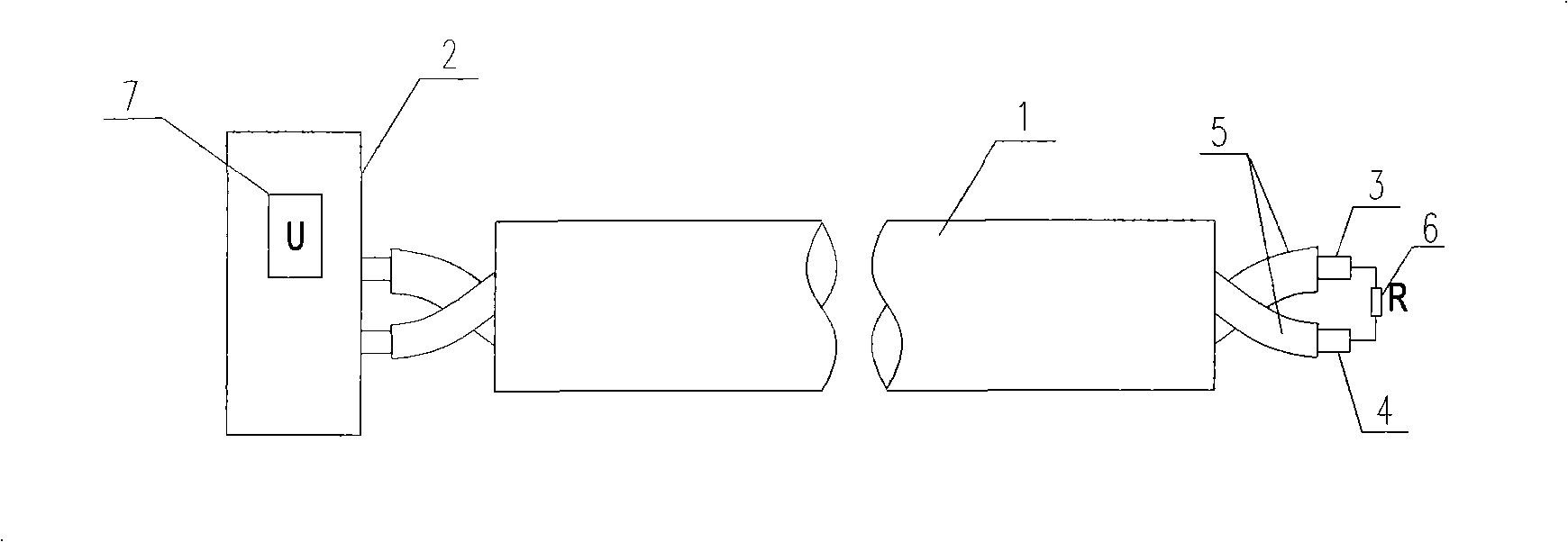

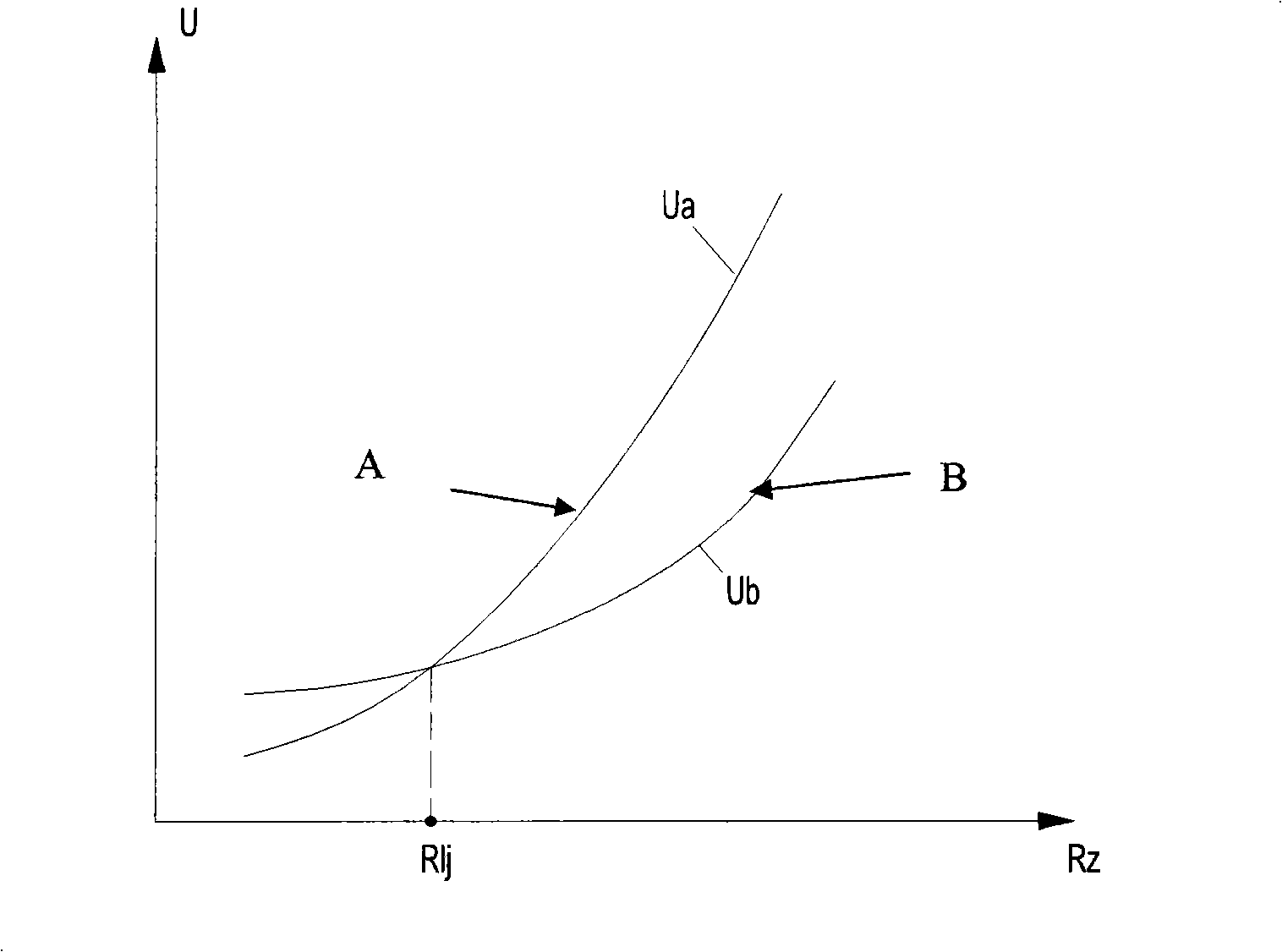

Embodiment 1

[0018] like figure 2 As shown, the thermocouple-based linear temperature-sensing fire detector provided in this embodiment includes a linear temperature sensing element 1; one end connected to the linear temperature sensing element 1 has a voltage monitoring unit 7 inside, so that the entire circuit can be detected in real time The voltage value can be processed at the same time, and the conversion box 12 that outputs the alarm signal when the alarm parameter of the entire loop exceeds the alarm threshold; and the terminal resistance 6 that is connected to the other end of the online temperature sensing element 1 and acts as a circuit breaker; Wherein the linear temperature sensing element 1 includes two detection conductors 3, 4 and an NTC characteristic barrier layer 5 arranged in parallel between the two detection conductors 3, 4, and at least one of the two detection conductors 3, 4 is a thermocouple wire; the resistance value Rz of the terminal resistance 6 is greater th...

Embodiment 2

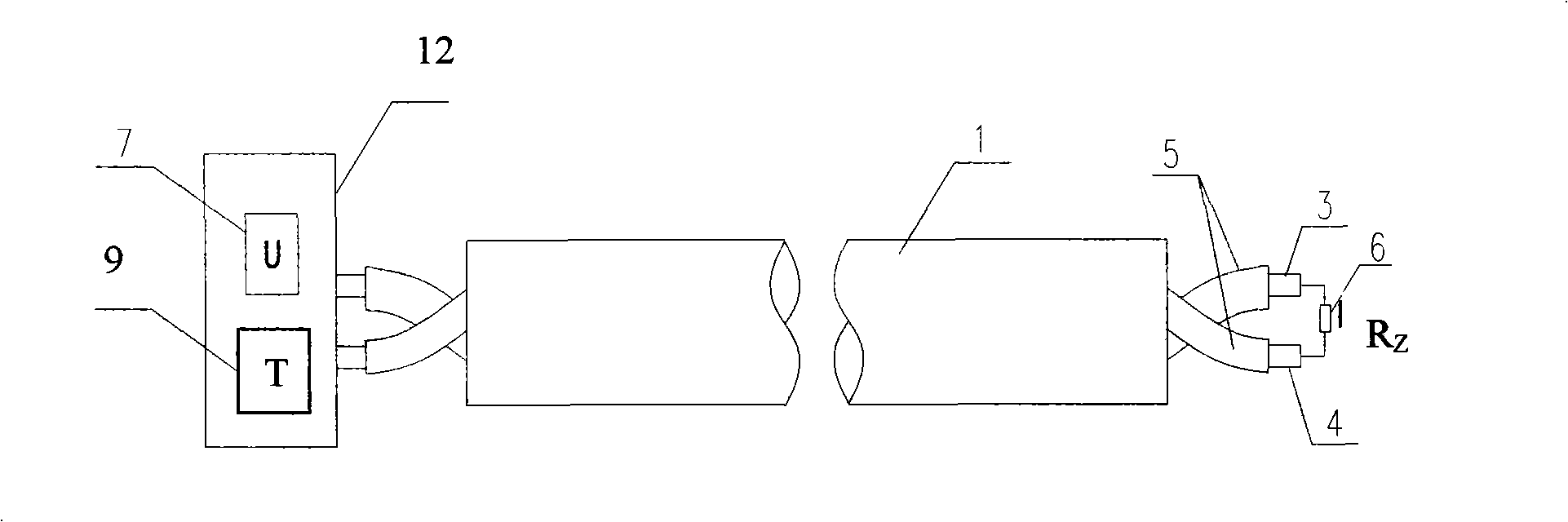

[0025] This embodiment is an improvement on the basis of Embodiment 1, as image 3 As shown, the thermocouple-based linear temperature-sensitive fire detector provided in this embodiment is to add a resistance monitoring unit 8 that can work alternately with the voltage monitoring unit 7 in the conversion box 12 in the first embodiment, and the rest is the same.

[0026] This is because when the resistance measuring unit 8 is not installed in the switch box 12 of the detector, the switch box 12 performs fault judgment based on the abrupt change of the measured voltage caused by the disconnection. When an open circuit fault occurs at the end of the terminal resistor 6, the voltage value monitored by the conversion box 12 will change abruptly, so it is feasible to judge the fault simply based on monitoring the above voltage value. However, when the disconnection occurs at a certain part of the line-type temperature sensing element 1 between the terminal resistor 6 and the conver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com