Applying apparatus, and applying method

A coating device and coating technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of difficult adjustment of bolts, gap changes, and inability to evenly coat the coating liquid, etc., to achieve easy adjustment Effect

Active Publication Date: 2009-08-26

FUJIFILM CORP

View PDF2 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] However, in the inventions disclosed in Patent Document 1 and Patent Document 2, although the gap between the tip lip and the plate can be adjusted, since the adjustment is performed by tightening and tightening the bolts, the bolts usually have It is difficult to adjust to an accurate position due to play, etc., and due to the lack of reproducibility of the adjustment, it is necessary to repeatedly adjust the bolts to be successful occasionally.

In addition, in this adjustment by bolts, there will be many practical problems such as the following: the bolts are loosened during the coating process due to the vibration of the rotating body of the coating device, and the gap changes, resulting in uneven coating. Coating fluid applied; plate breakage

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0041] Next, the comparative test results of Examples and Comparative Examples of the present invention will be described.

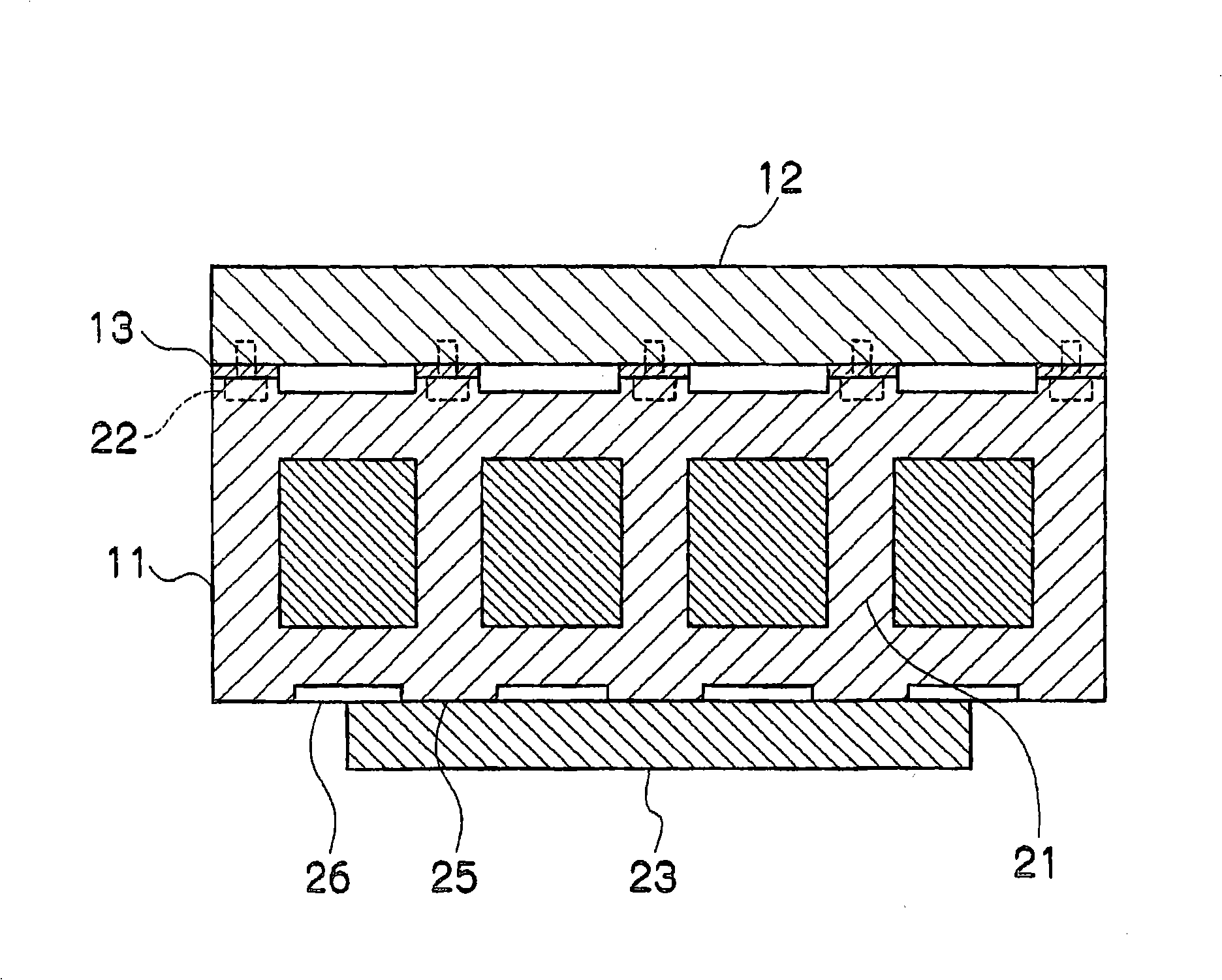

[0042] (1) Conditions of the coating die and the stand of the examples are as follows.

[0043] (coating mold)

[0044] As a coating die, a die having a total length of 1400 mm and an effective coating width of 1250 mm was used.

[0045] (shelf)

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

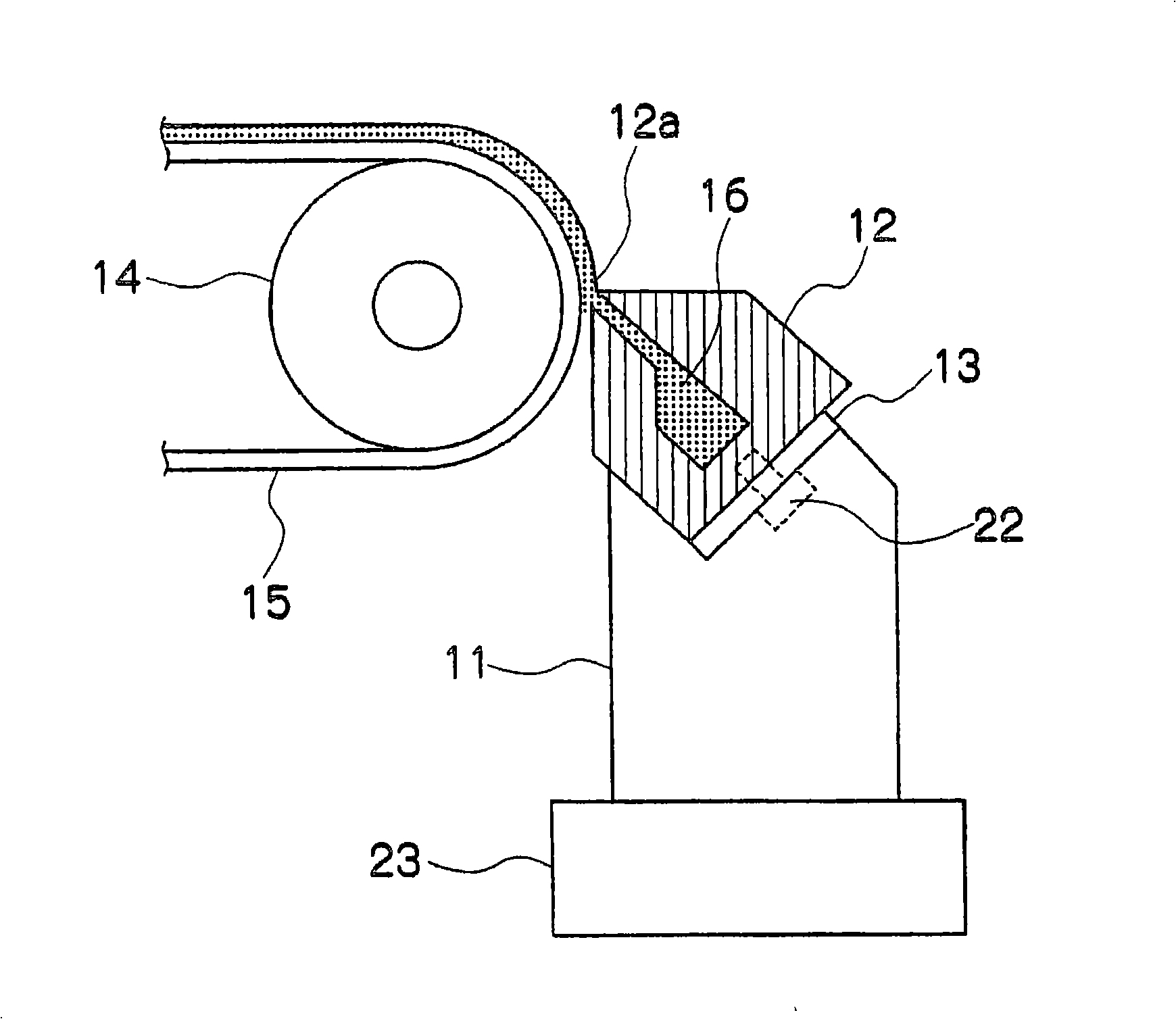

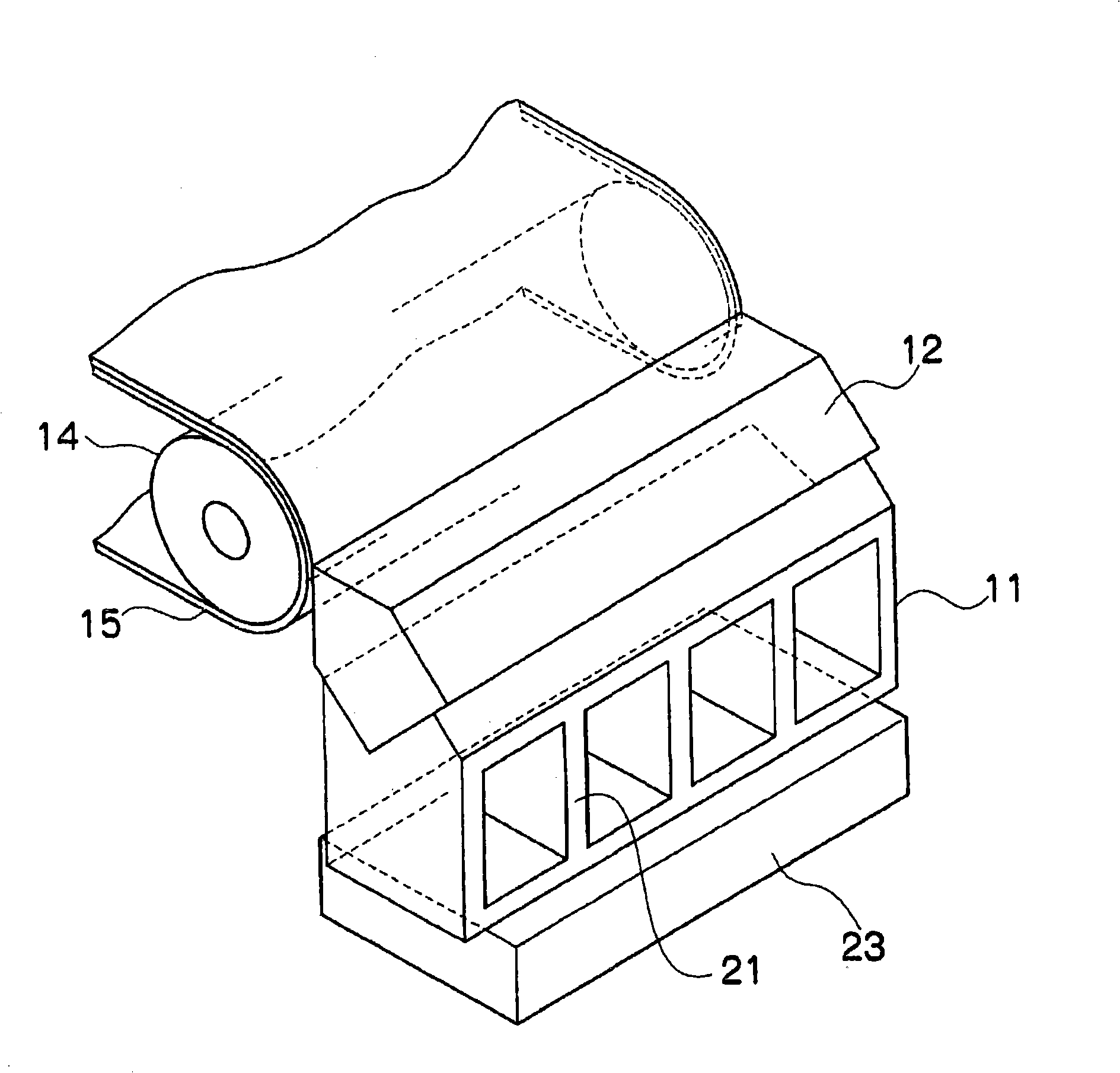

Intended is to homogenize stably the clearance between the tip lip of an applying die and a web. Provided is an applying apparatus for applying an application liquid to a moving web from the tip lip of the applying die fixed on a bed. The applying apparatus is characterized in that a plurality of shims fixed on the bed by bolts are arranged in that joint zone of the jointing face of the bed which is to be jointed to the applying die, so that the straightness of the tip lip of the applying die is adjusted by adjusting the individual thicknesses of the shims arranged.

Description

technical field [0001] The present invention relates to a coating device and a coating method, in particular to a coating used to form photosensitive emulsifiers, magnetic fluids, viewing angle-enhancing films, and antireflection films on supports such as plastic films, paper, and metal foils. A coating device and a coating method for a coating liquid such as a solution, a pigment liquid for color filters, a solution for forming a surface protection film, and the like. Background technique [0002] As a method for applying a coating liquid to the surface of a moving support (plate, etc.), a die coating method is known. In recent years, along with the high performance of the film formed by the die coating method, etc., a technology for forming a high-precision laminated film in a thinner lubricating film thickness of 20 [μm] or less has been demanded. In order to uniformly form such a thin film, the accuracy of the coating device, particularly the gap between the front end l...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B05C5/02B05D1/26

CPCB05C5/0245B05C5/0262B05C5/0254B05C5/02B05D1/26

Inventor 山田健央小岛和也

Owner FUJIFILM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com