Fibrous web processing apparatus with a metal belt loop

A technology of processing equipment and fiber web, which is applied in the field of fiber web processing equipment, can solve problems such as fiber web rupture and metal belt damage, and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

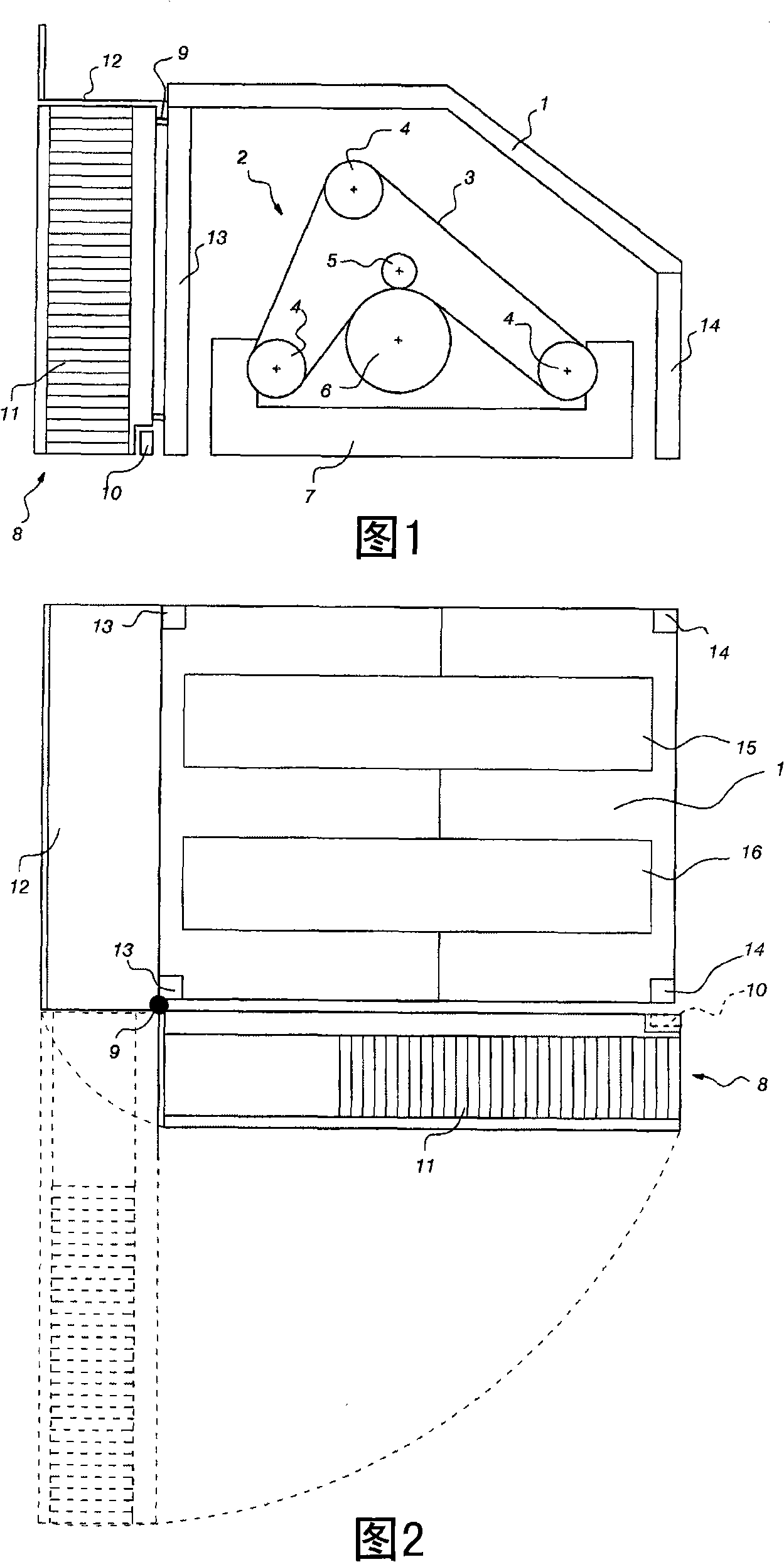

[0009] figure 1 , the reference number 2 designates a metal belt calender comprising a calender belt 3 rotating around a guide roll 4, and on the outside of the calender belt is a backing roll 6, preferably a heated roll , whereby a web processing zone is formed between the calendering belt and the back pressure member, through which zone the web to be calendered is guided. Furthermore, on the inside of the metal belt loop 3 are press rolls 5 serving as pressing means, which press the metal belt against rolls 6 so as to create a higher pressure in the calender zone of the nip. These guide rollers, or at least some of them, may be arranged to be movable to adjust the tension of the belt 3 as required. Reference numeral 7 denotes a body portion of the metal belt calender. The technical solution according to the invention consists of a protective structure separate from the metal belt calender, in the direction of travel of the fiber web (in figure 1 with figure 2 Viewed fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com