Electrodeless discharge lamp, and lighting equipment, and method for manufacturing electrodeless discharge lamp

A discharge lamp and electrodeless technology, applied in lighting devices, gas discharge lamp parts, discharge lamps, etc., can solve the problems of controlling the coldest spot temperature, temperature rise, light output drop, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

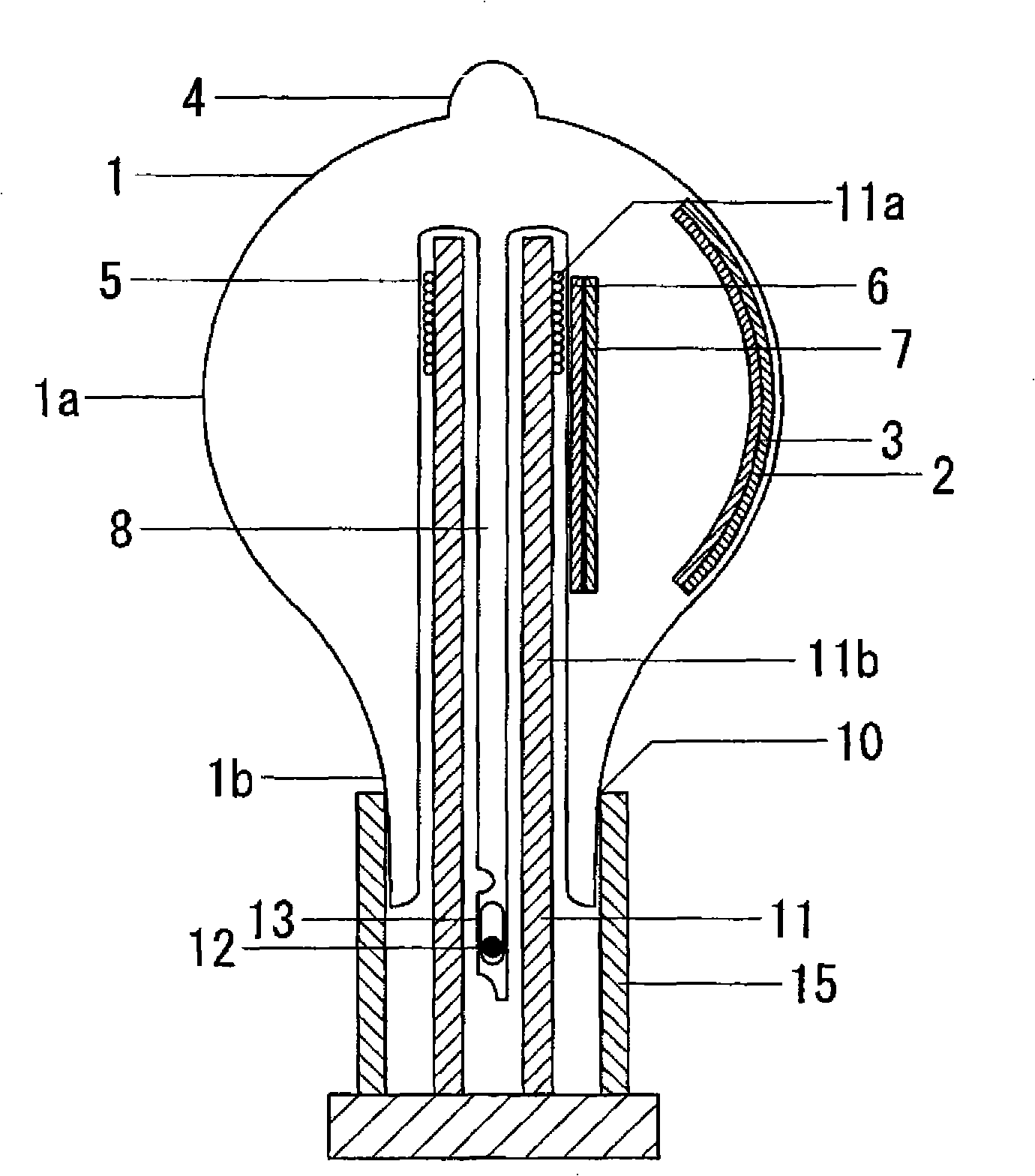

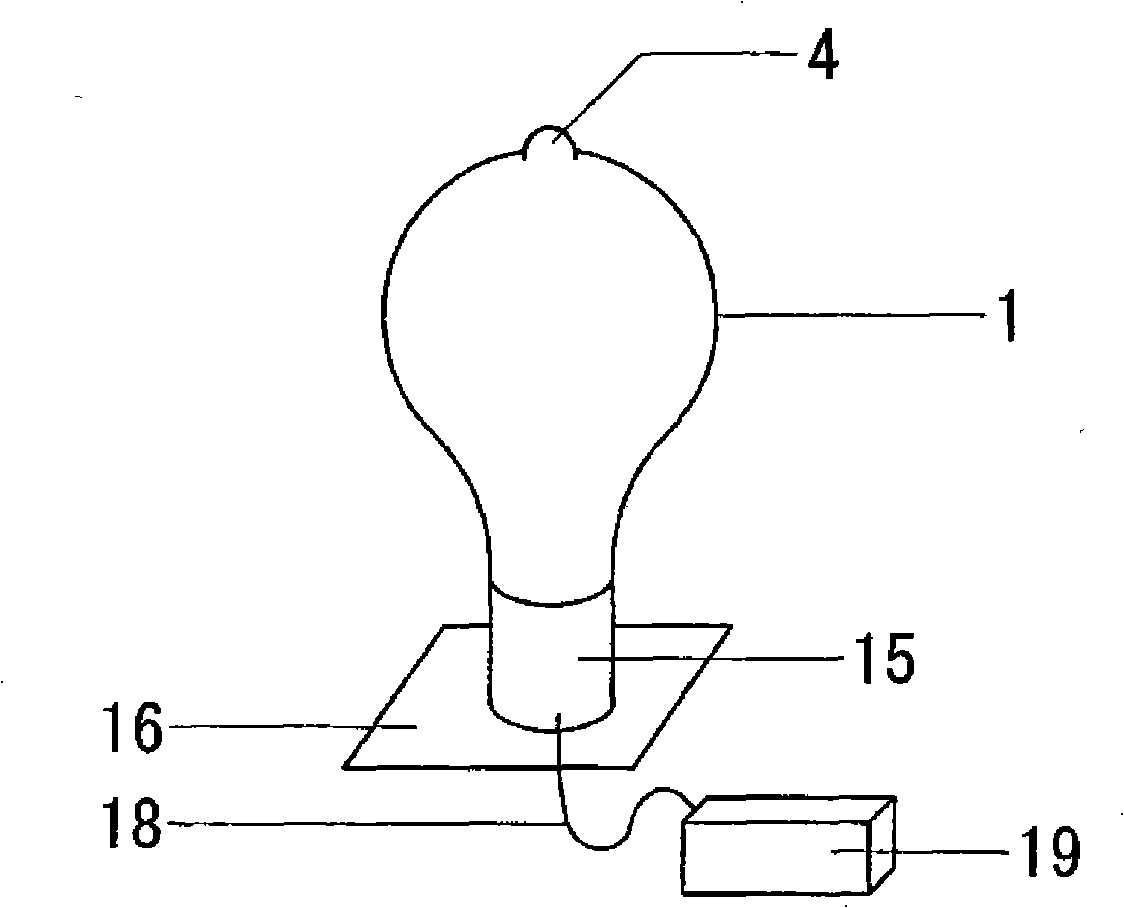

[0040] figure 1 A cross-sectional view of the electrodeless discharge lamp of this embodiment is shown. figure 2 A schematic diagram of a lighting device including the lamp of this embodiment is shown.

[0041] The electrodeless discharge lamp includes a bulb 1 made of a light-transmitting material such as glass, and mercury and an inert gas such as argon or krypton are enclosed inside the bulb 1 .

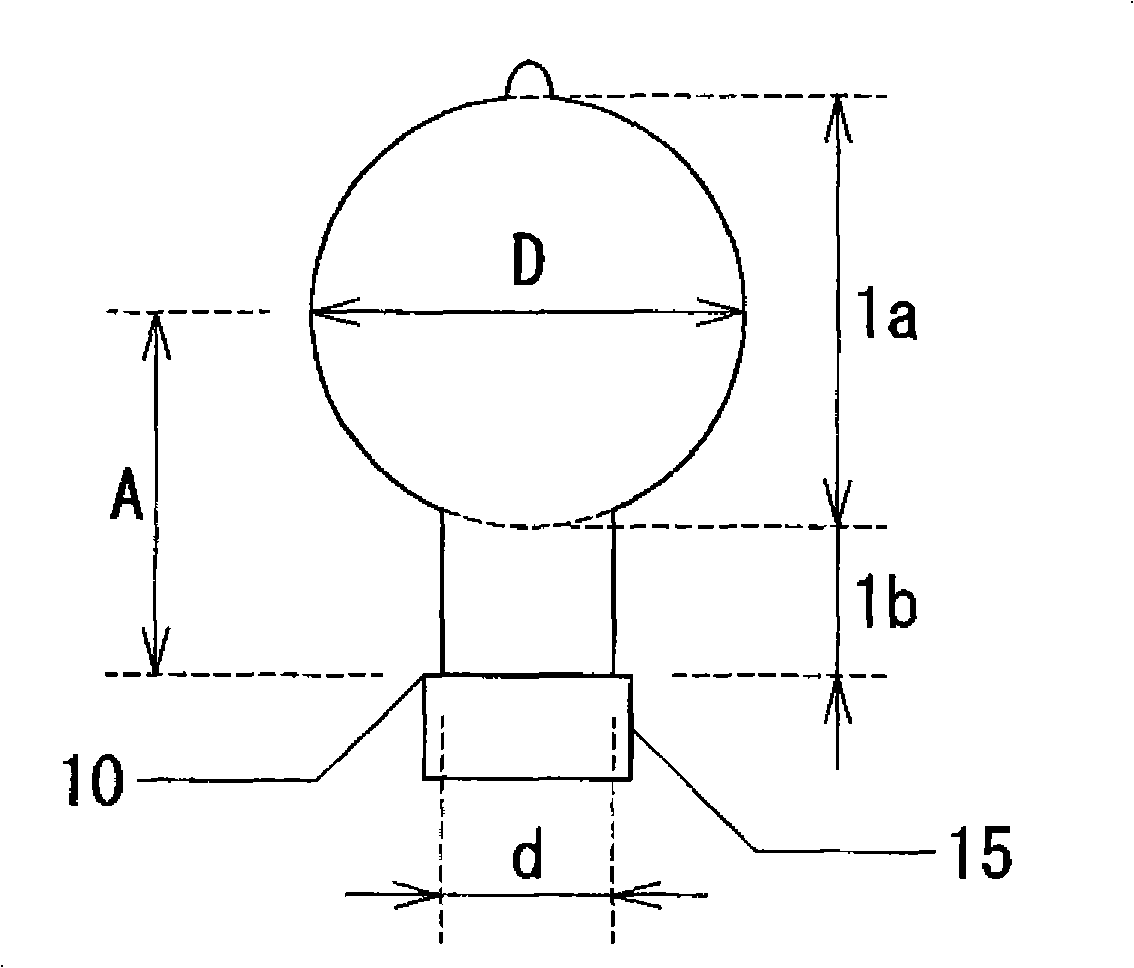

[0042] The sealed bulb 1 comprises: a substantially spherical bulb 1a; a neck 1b extending from the bulb 1a; a cavity 5 extending from the neck 1b to the bulb 1a, in which is inserted a coupling described below. device 11; a fine exhaust pipe 8 disposed inside the cavity 5, and the thin exhaust pipe 8 runs from the bottom of the cavity 5 toward the opening of the cavity.

[0043] The boss 4 is on the opposite side of the neck 1b (ie, on the figure 1 The upper end of the spherical portion 1a) is formed on the top end of the spherical portion 1a, and protrudes to the outside of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com