Interface detection method based on optical interface detector

A detection method and optical interface technology, applied in scientific instruments, material analysis through optical means, instruments, etc., can solve the problems of large signal fluctuations, weak optical signals, low resolution, etc., and achieve obvious effects, good stability, Apply flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment one: calibration and test method of the present invention

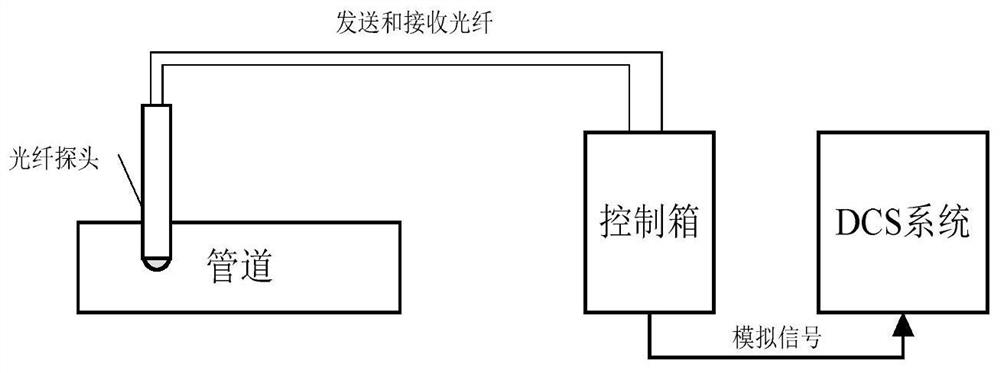

[0046] As attached to the manual figure 1 Shown:

[0047] Step 1: Connect the output end and input end of the fiber optic probe to the optical sending and receiving devices in the control box respectively. The distance between the probe and the control box is 10m (2km), and connect the output signal of the control box to the DCS end;

[0048] Step 2: Prepare several bottles that are completely protected from light, fill the bottles with several media that need to be tested, and mark them well. During this process, the media cannot be exposed to light, and the better the shading of the bottle, the more accurate the test results higher;

[0049] Step 3: Wipe the fiber optic probe clean, power on the control box, set the system temperature, wait for the temperature in the control box to be constant, and then insert the probe into the water. At this time, the signal value will be displayed on the scre...

Embodiment 2

[0053] Embodiment 2: The present invention is based on the interface detection method of the optical interface detector

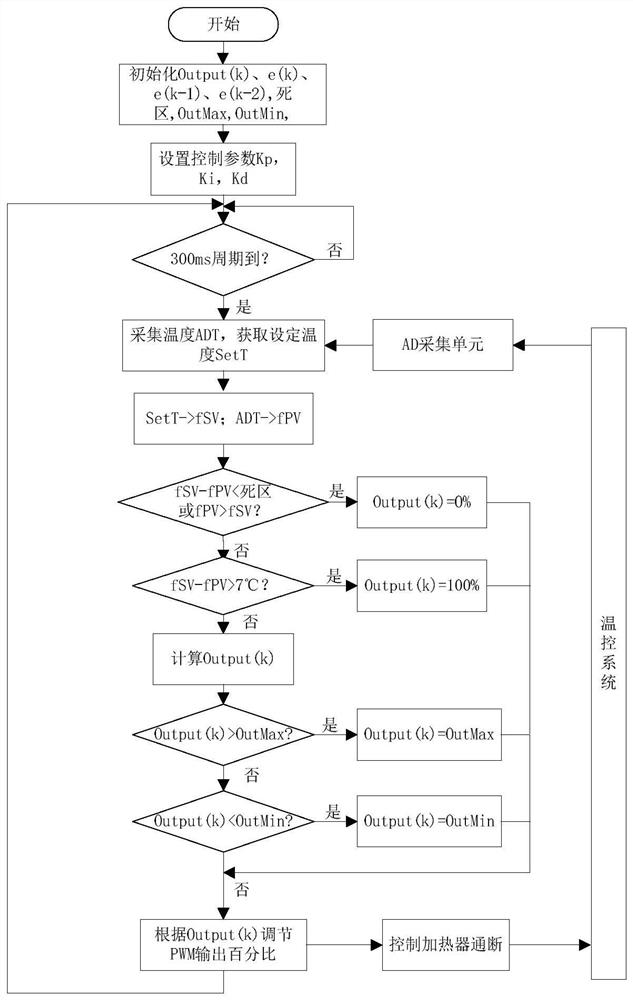

[0054] (1) Temperature control

[0055] As attached to the manual figure 2 As shown in the control box, the luminous and photoelectric conversion areas are heated, internally circulated, and heat-insulated, and a temperature detection chip is installed near the semiconductor laser to obtain the real-time temperature of the area. According to the temperature and the set temperature, The closed-loop temperature control algorithm is used to adjust the PWM output percentage to control the on-off of the heater, and finally make the area in a constant temperature state. When the difference between the actual temperature and the target temperature is greater than 7°C, full-speed heating is adopted to save the heating time of the system, and when it is less than 7°C, it enters closed-loop temperature control to adjust heating.

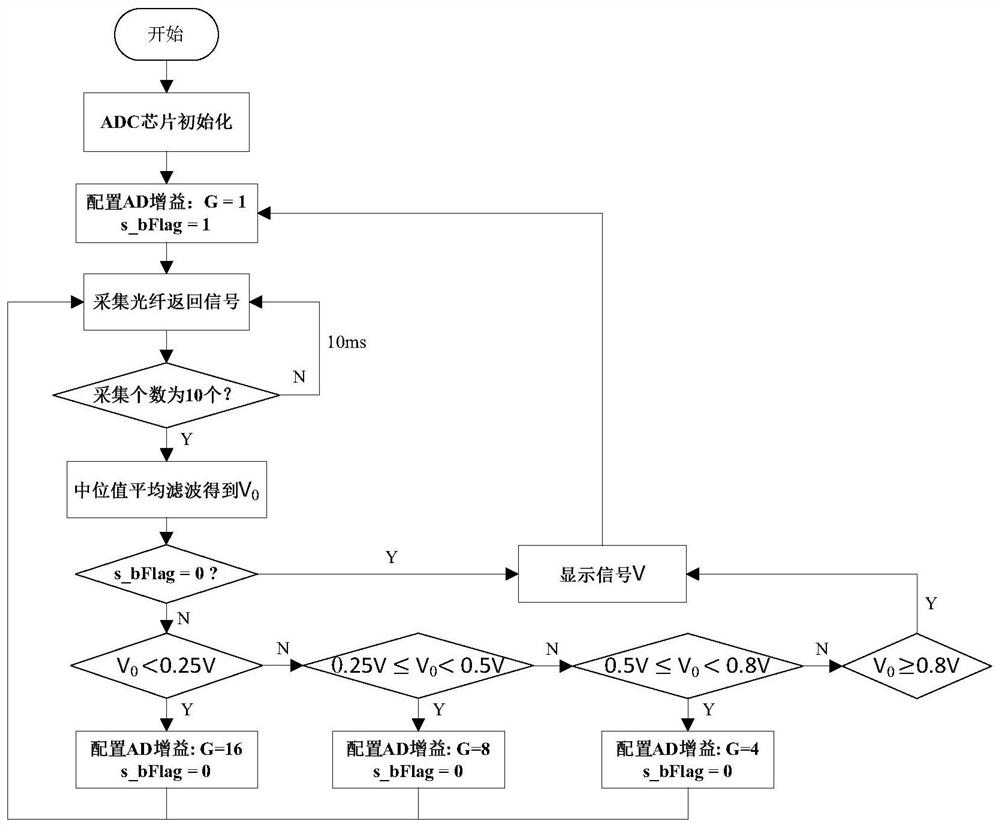

[0056] (2) Automatic gain adjustm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com