Seabed automatic lobster catching cage

A technology of lobster and shrimp cages, which is applied in fishing, application, animal husbandry, etc., can solve the problems of increasing the difficulty of lobsters entering the cage, the anti-escape function is not ideal, and it is inconvenient for lobsters to enter at the same time, so as to improve the shrimp catching ability, The effect of preventing lobster from escaping and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

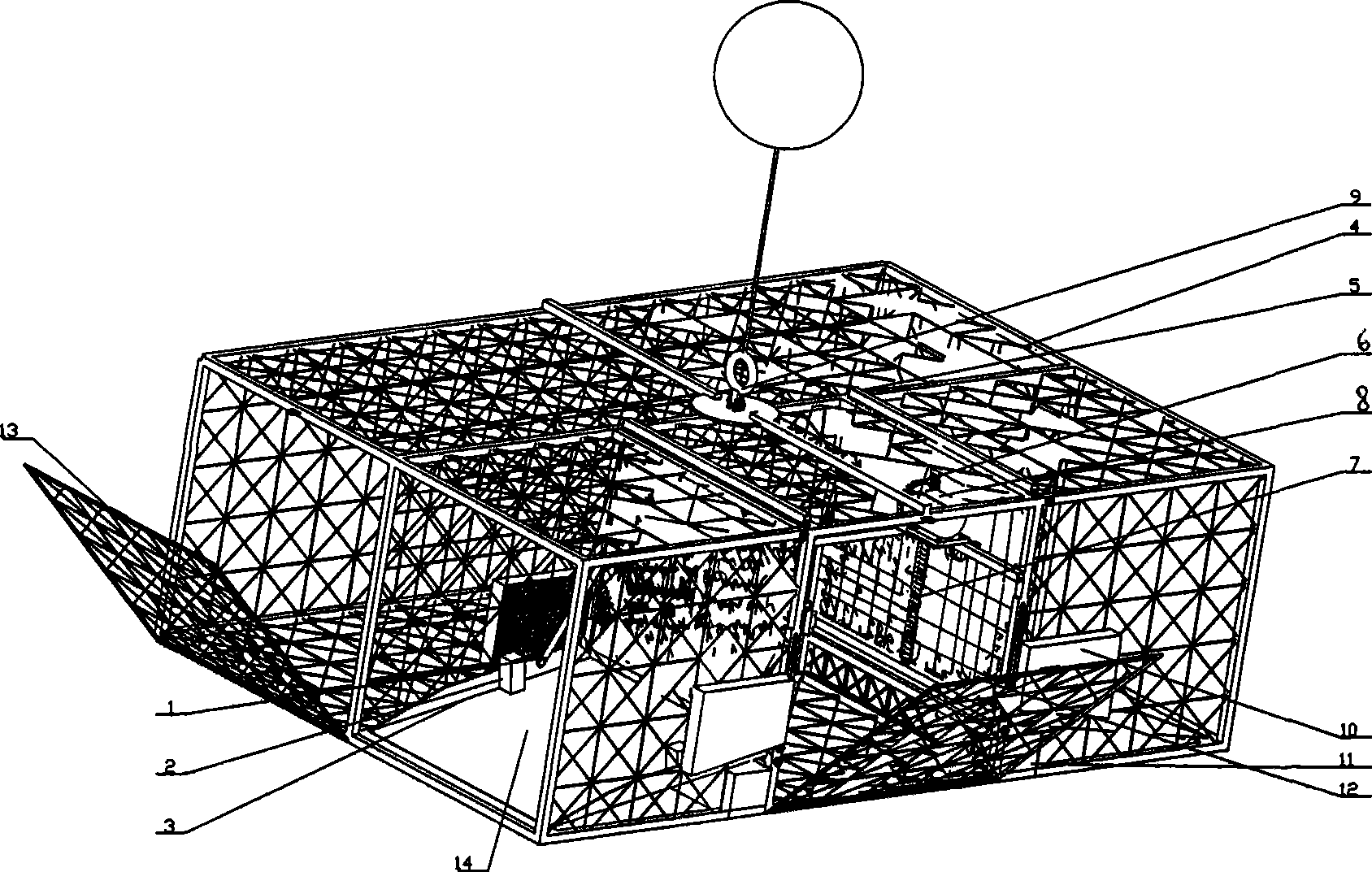

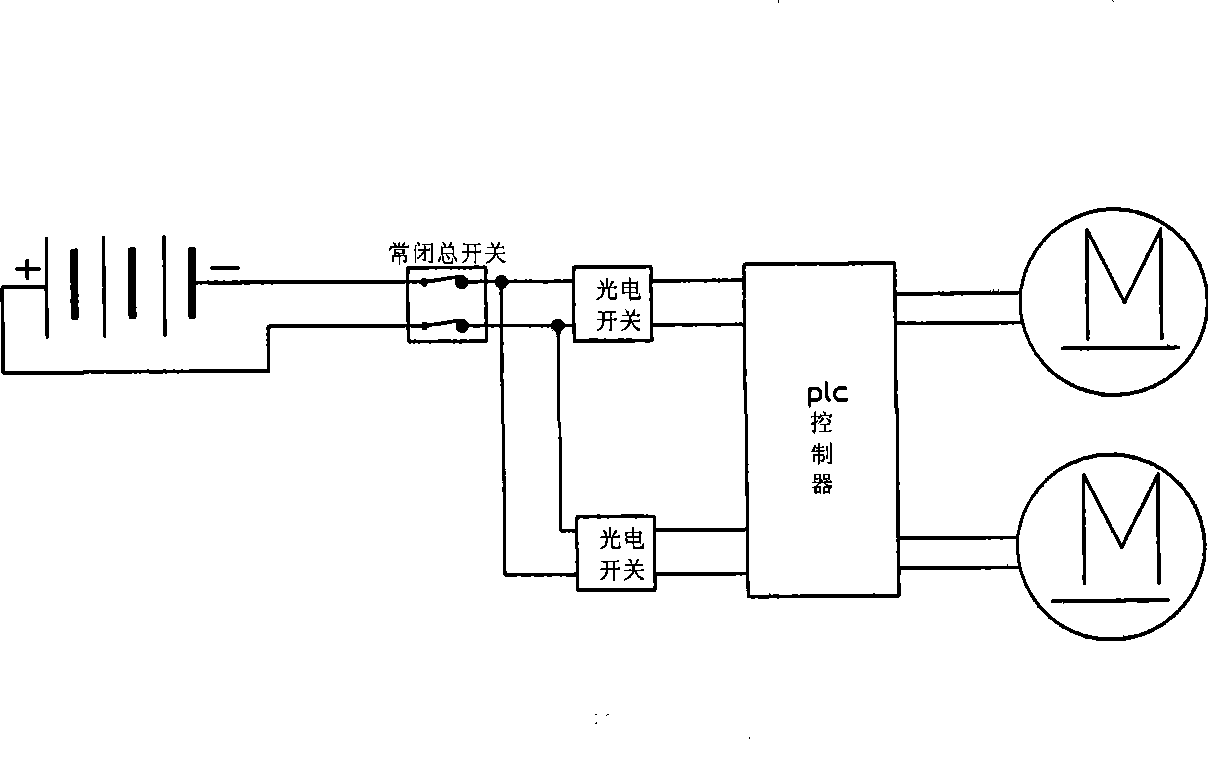

[0013] Such as figure 1 Shown, a kind of seabed automatic lobster trap includes shrimp pot 4, fishy lure box 10, lobster entrance 14 and forms, and fishy lure box 10 is located in the shrimp pot 4, and lobster entrance 14 is located at the two ends of shrimp pot 4, so The inner port of the lobster entrance 14 described above is provided with an electric lifting gate 5 and a gate lifting device, and the outside of the electric lifting gate 5 is provided with a shrimp bridge plate 3, and the shrimp bridge plate 3 is provided with a light control for controlling the lifting of the electric lifting gate. The switch 2, the connecting rod 1 is arranged between the shrimp bridge plate 3 and the electric lift gate 5, one end of the shrimp bridge plate 3 is hingedly connected with the shrimp cage 4, and the position near the other end of the shrimp bridge plate 3 is hingedly connected with the connecting rod 1, The other end of connecting rod 1 is hingedly connected with electric lifti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com