Hand-drying apparatus and hand-drying method

A hand dryer and sensor technology, which can be applied to household appliances and other directions, can solve the problems of high manufacturing cost, lack of practicability, and no cloth to wipe hands.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

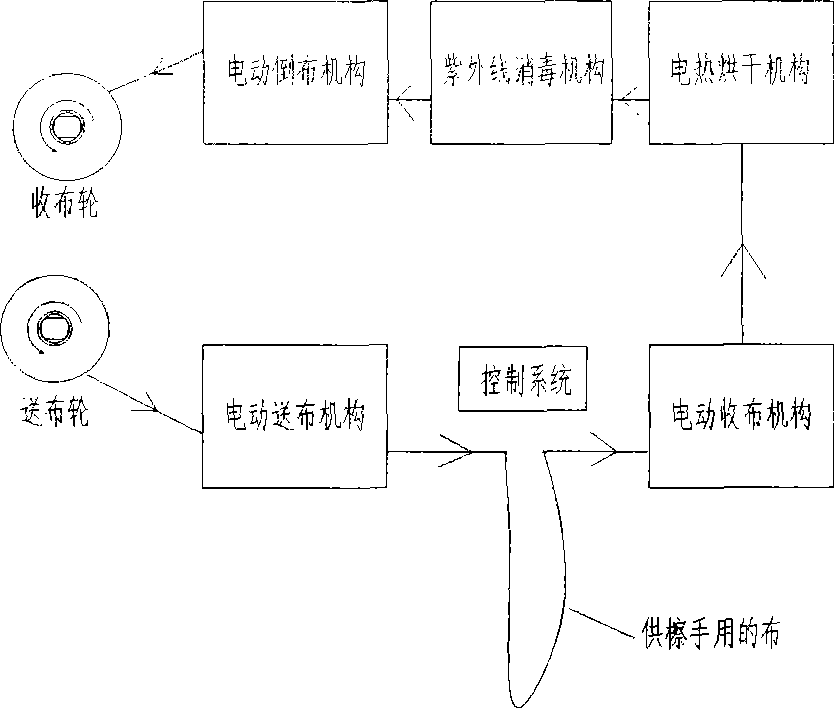

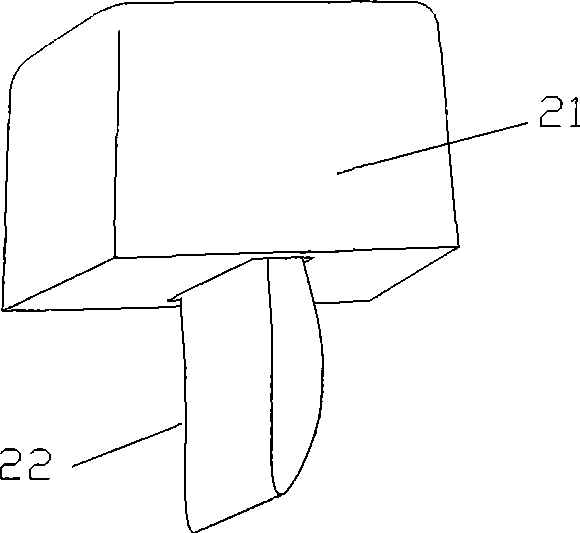

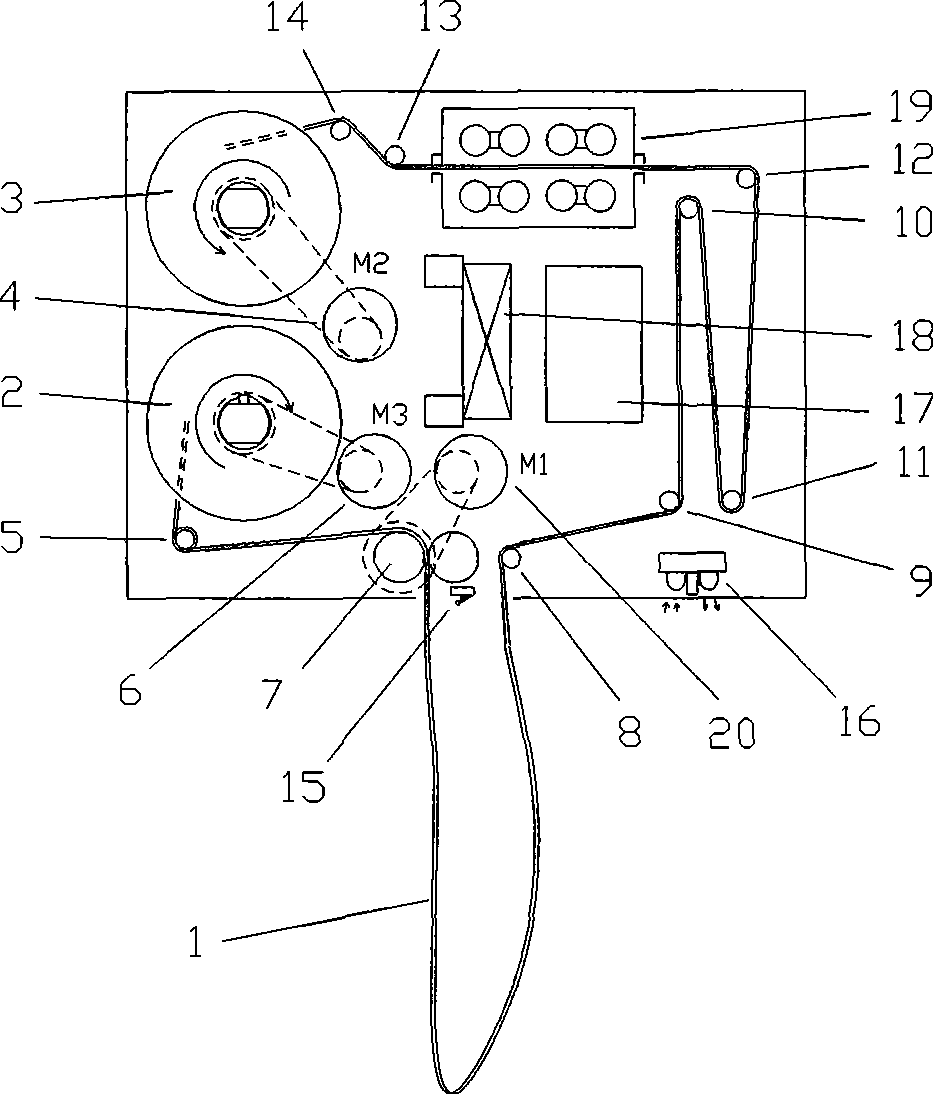

[0016] Embodiment 1: with reference to attached Figure 1~3 . Hand dryer 21, which includes a hand dryer shell and a control device, is composed of a cloth feeding wheel, a cloth feeding mechanism, a tensioning mechanism, an electric heating drying mechanism, a disinfection mechanism, a cloth reversing mechanism and a cloth receiving wheel. On the shaft, there is a cloth roll on it, and the cloth head in the cloth roll is connected with the cloth take-up wheel. The cloth feeding mechanism and the tensioning mechanism are respectively located on both sides of the lower cloth opening of the hand dryer shell, and the electric heating drying mechanism is located on the side of the tensioning mechanism. And the hot air directly blows the cloth surface (the electric heating drying mechanism is made of electric heating wire 17 and fan 18, and the electric heating wire 17 is positioned at the air outlet of fan 18, or the electric heating drying mechanism adopts hot air blower to dry)....

Embodiment 2

[0017] Embodiment 2: On the basis of Embodiment 1, the hand drying method of the hand dryer, before use, the cloth feeding motor 20 drives the counter-pressing cloth feeding roller 7 to rotate, and the counter-pressing cloth feeding roller 7 passes the clean cloth through the guide roller 5 Guide and send the cloth 22 in the cloth roll on the cloth feeding wheel 2 to the lower part of the hand dryer. When the hand reaches the bottom of the hand dryer, the sensor 16 is used to get a signal, and the control device confirms that the hand dryer is in use. In the process, when the signal of the sensor 16 disappears after the person wipes his hands and leaves the hand dryer, the control device receives the signal transmitted by the sensor 16 and instructs the cloth receiving motor 4 to drive the cloth receiving wheel 3 to rotate, and the used wet cloth passes through the guide. Roller 8 and the S-shaped tensioning mechanism tension the cloth surface. At this time, the electric heatin...

Embodiment 3

[0018] Embodiment 3: On the basis of Embodiment 1 or 2, when the hand dryer is not in use, the cloth rewinding motor 6 drives the cloth feeding wheel 2 to rotate, and the cloth belt is rolled back from the cloth receiving wheel 3 to the cloth feeding wheel 2 , the wet cloth sent back from the cloth receiving wheel passes through the ultraviolet disinfection lamp 19 for sterilization and disinfection on both sides, and then enters the S-shaped cloth composed of the upper tension roller 10, the upper tension roller 12, the lower tension roller 9, and the lower tension roller 11. With a drying area, the fan 18 blows the wind over the surface of the heating wire 17, the hot air dries the wet cloth, and the cloth rewinding motor 6 rewinds the sterilized and dried clean cloth to the cloth feeding wheel to realize recycling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com