Self-adjusting quick reaction kettle

A fast-response, self-adjusting technology, applied to chemical/physical/physical-chemical fixed reactors, etc., can solve problems such as long reaction time, insufficient reaction, increased side reactions, etc., and achieve good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

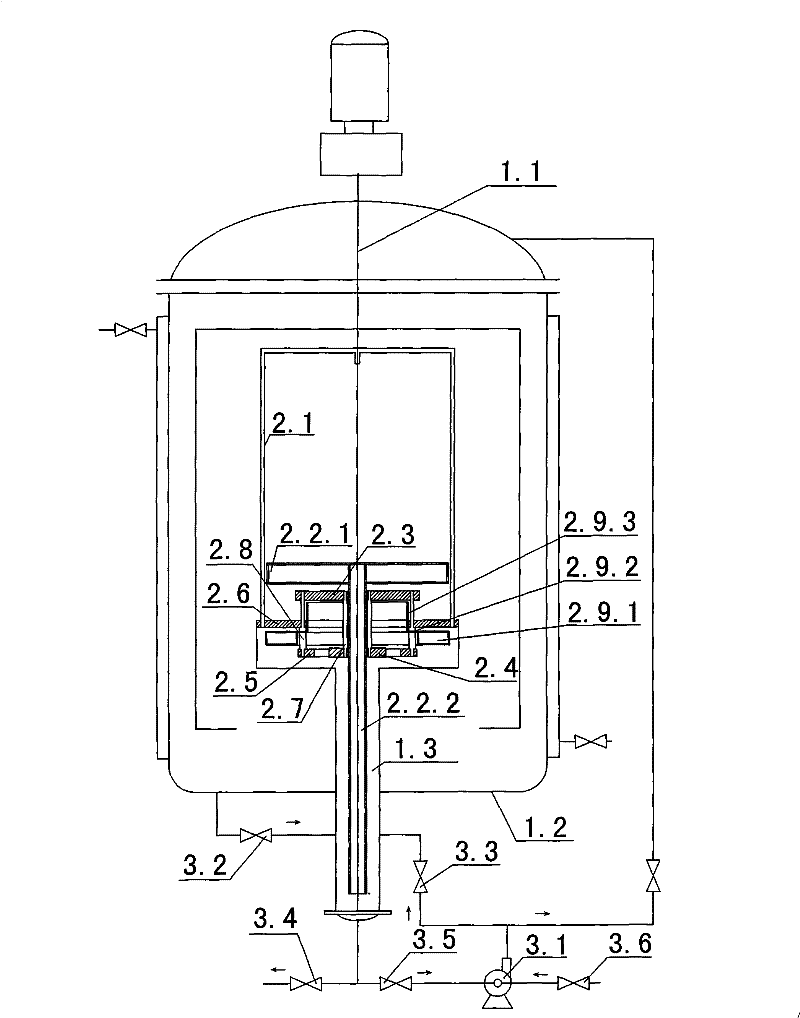

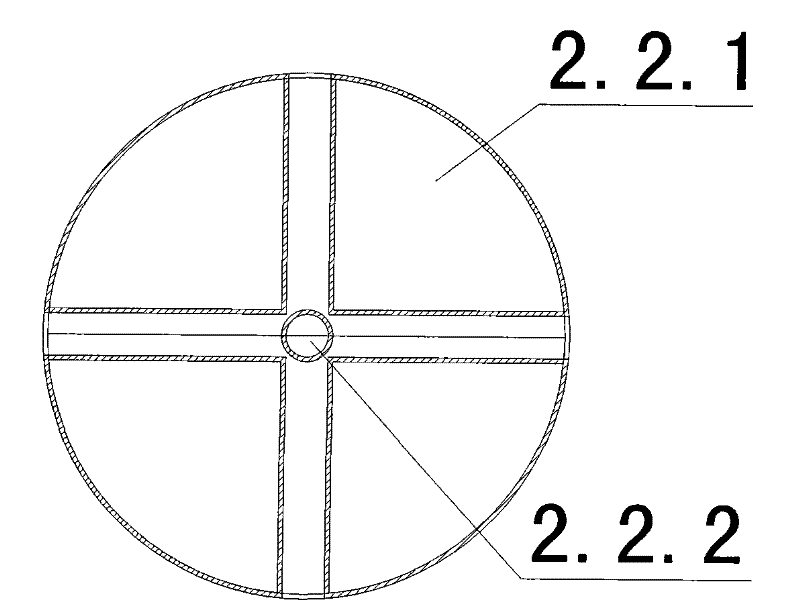

[0013] Refer to attached figure 1 , The outside of the kettle body 1.2 is provided with a material inlet and outlet and a driving motor. A fork-type stirrer 1.1 structure is installed inside the kettle body, and the structural feature is a 2-fork or multi-fork structure coaxial with the stirring motor; the lower part or other parts of each fork have forks, which are used for stirring various materials in the reactor. There is a central chamber tube 1.3 under the trough floating body 2.2.1 so as to cooperate with the internal components of the reactor to work. The structural feature of component 1.3 is that it is vertical to the center of the reactor, its cross-section is circular or other geometric shapes, and the cross-section can be different at different heights; the part exposed to the reactor shell has an interface, and the inside is used to install and adjust some components. And work together.

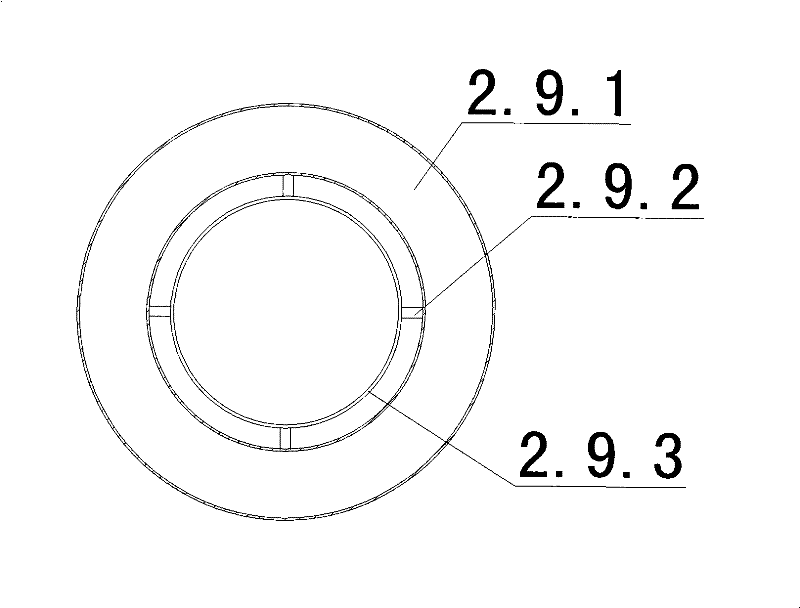

[0014] The adjustment part consists of air string 2.1, trough floating bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com