Proportion regulating and injecting system

An injection system and ratio adjustment technology, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., can solve the problems of large impact on injection quality, large fluctuations in chemical agent solution, and inconvenient operation, so as to save ground Investment, simplification of "one pump and multiple wells" process, and the effect of reducing viscosity loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

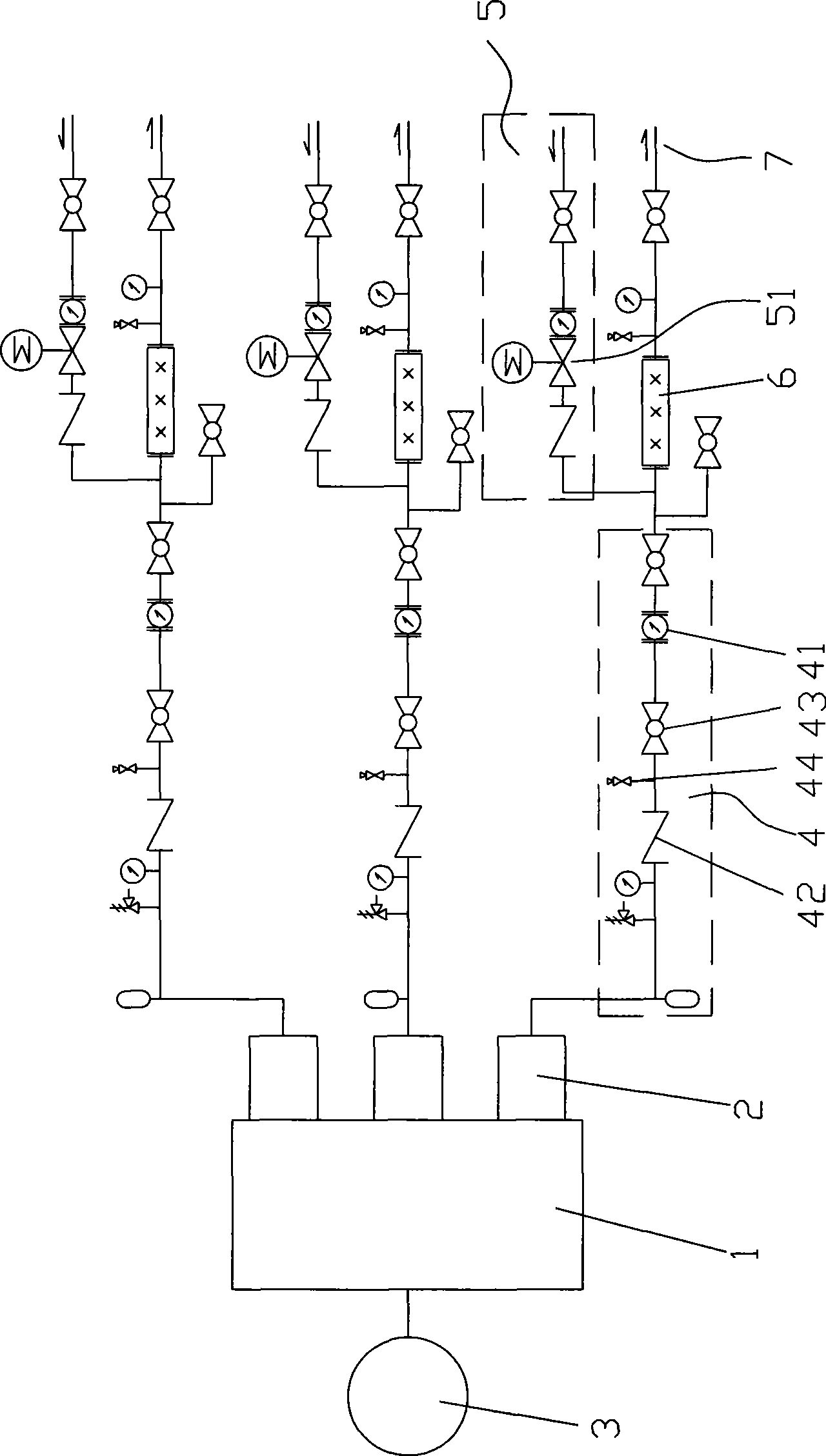

[0011] Such as figure 2 As shown, the proportional adjustment injection system of the present invention includes a booster pump 1, which is used to pressurize the chemical agent solution containing polyacrylamide, and the process pipe 3 provides an injection channel for the chemical agent solution containing polyacrylamide, and the booster pump 1 is provided with several pump heads 2, and the output of the chemical agent solution containing polyacrylamide is adjusted according to the needs. In this embodiment, three pump heads 2 are provided. In actual application, the number of pump heads can be increased or decreased according to the demand. The general number is 3 to 7; each pump head 2 corresponds to an injection well, and the follow-up pipeline connected to a pump head is used to provide an injection well with a chemical agent solution injection process containing polyacrylamide; each pump head 2 Both are equipped with a flow regulating mechanism to control the flow of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com