Condensate draining pipe and method for assembling a condensate draining pipe

A technology for condensate and drain pipes, which can be used in condensate prevention, transportation and packaging, heating/cooling equipment, etc., and can solve problems such as complicated condensate drain hoses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

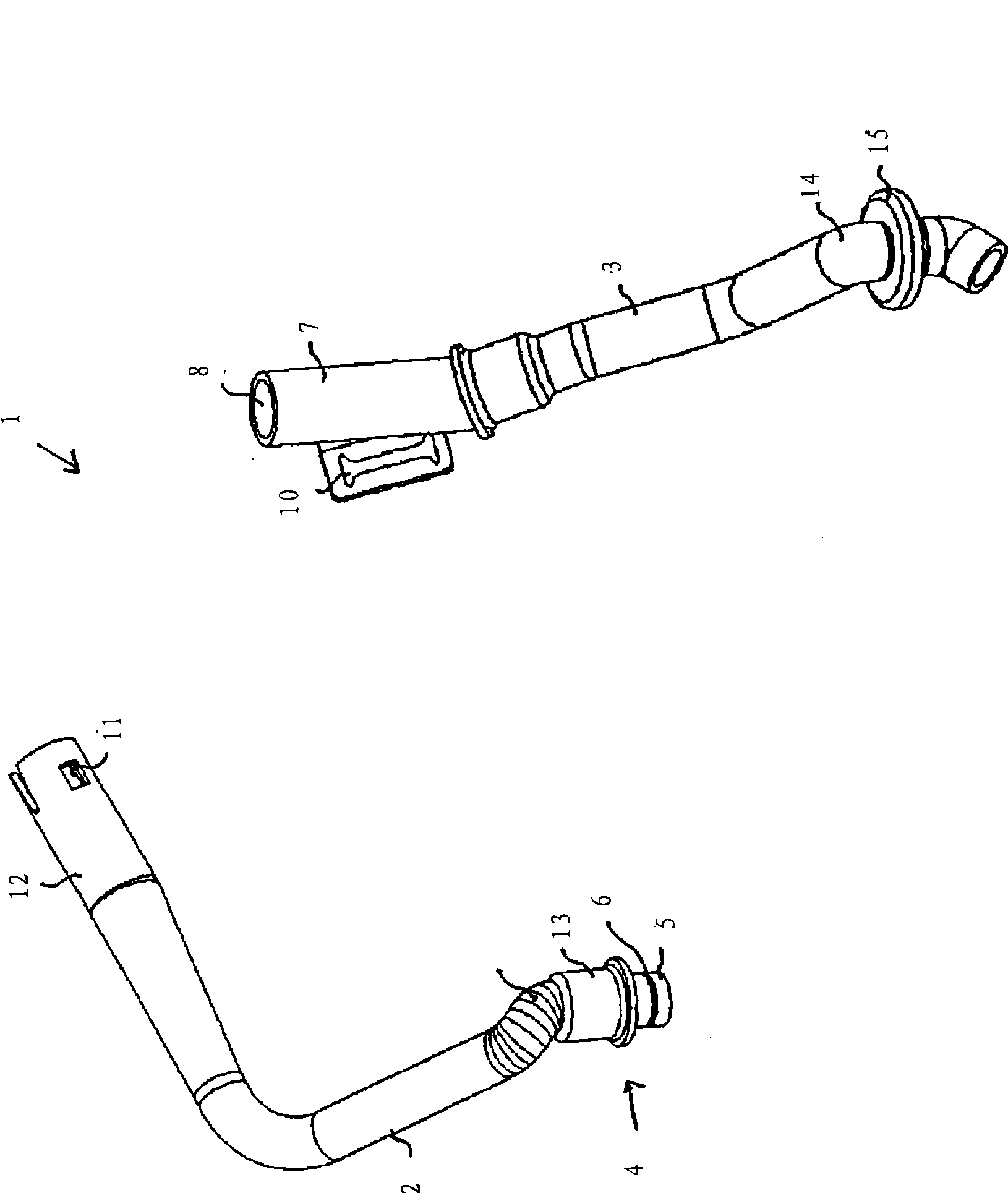

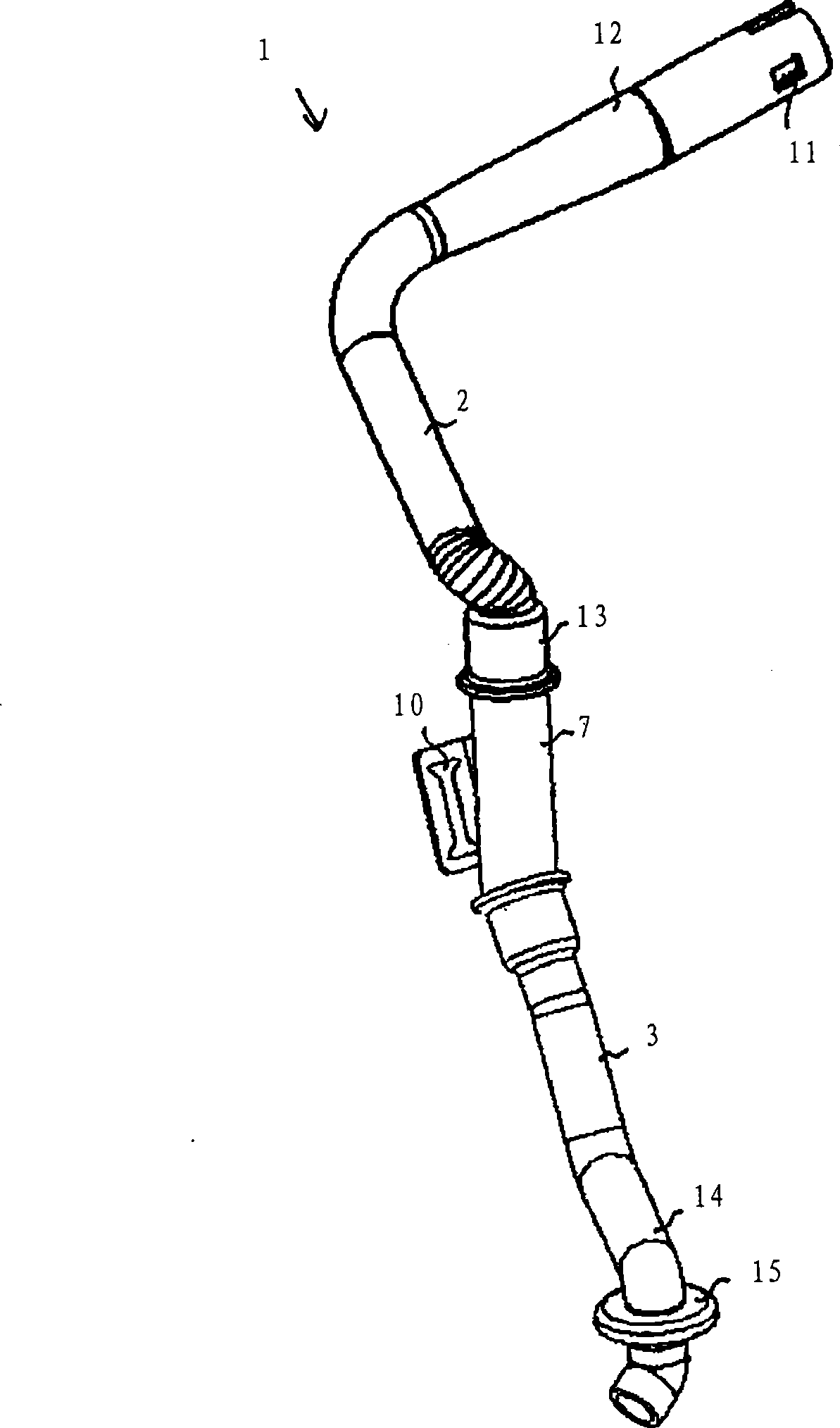

[0076] figure 1 and 2 Components of a condensate drain pipe 1 of an automotive heating, ventilation and / or air conditioning (HVAC) system according to a first embodiment of the invention are shown. figure 1 Each component is shown unassembled, figure 2 for the assembled components.

[0077] The condensate drain 1 comprises two separate fittings, the condensate supply 2 and the condensate drain 3 each having a generally tubular shape. The condensed water supply part 2 and the condensed water drain part 3 can be connected to each other through a coupling device 4 to form a condensed water drain pipe 1 .

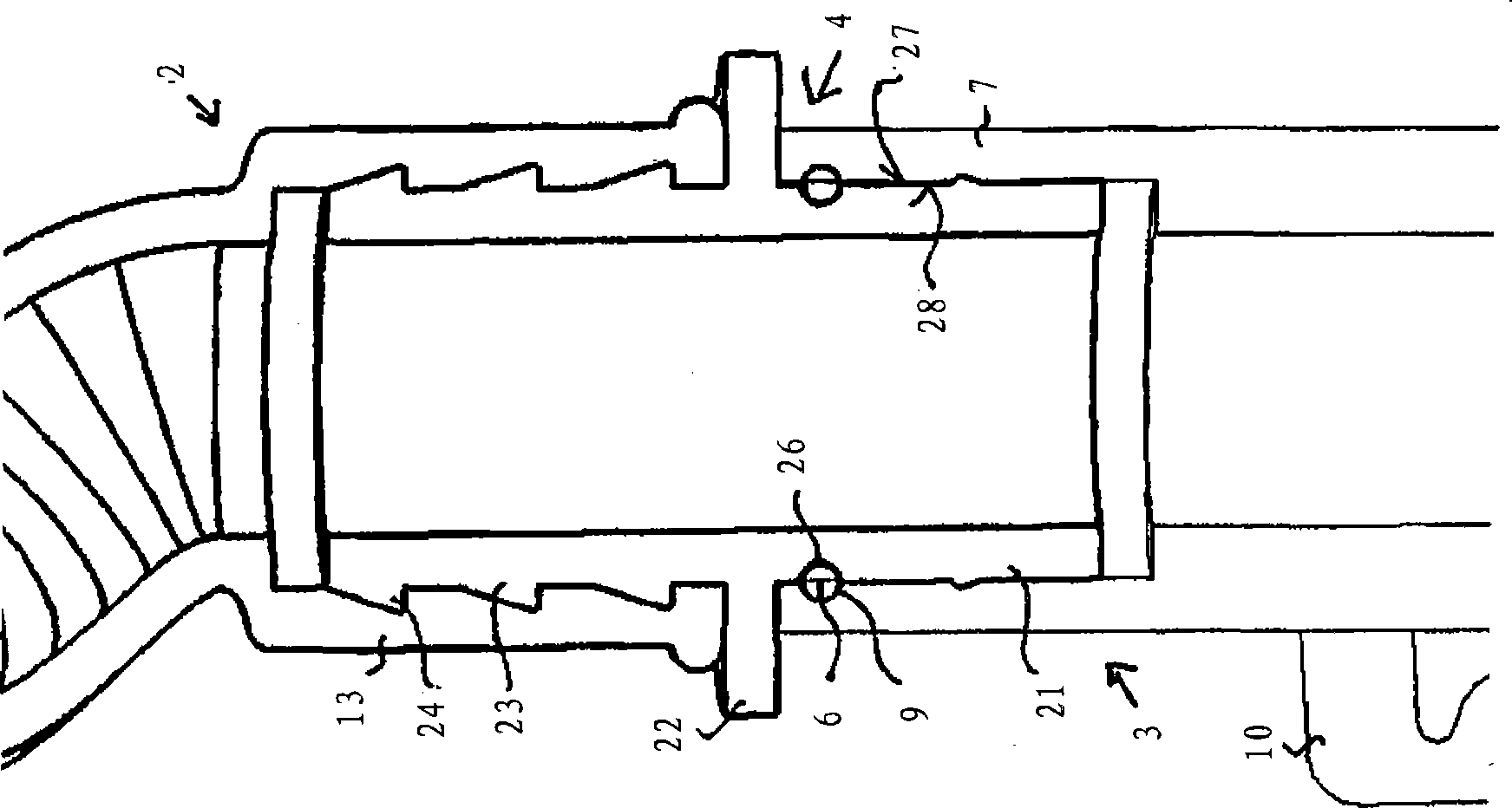

[0078] The coupling device 4 forms a press-fit joint enabling the detachable interconnection of the two separate parts 2 and 3 of the condensate drain pipe 1 . The coupling device 4 comprises a shaft fitting 5 , an O-ring seal 6 and a sleeve flange fitting 7 , which are shown in more detail in FIG. 3 .

[0079] The shaft fitting 5 is in the shape of a tubular nozzle which...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap