Telescopic type probe carrier

A telescopic, carrier-based technology, which is applied in the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, measuring devices, and use sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., to achieve long service life, good stability and reliability, and save manpower. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

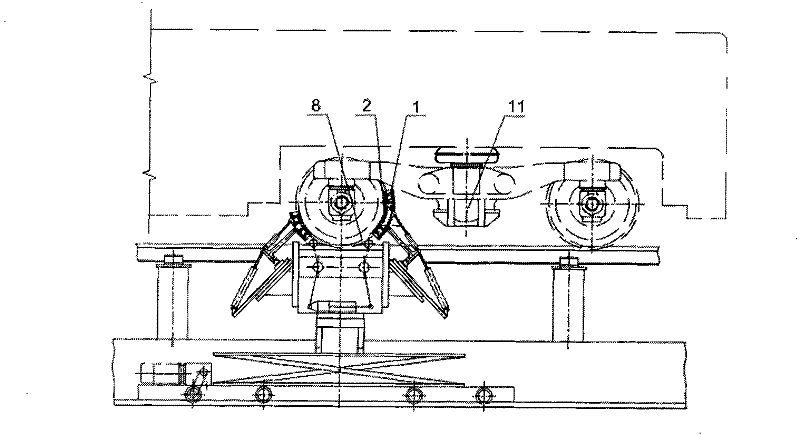

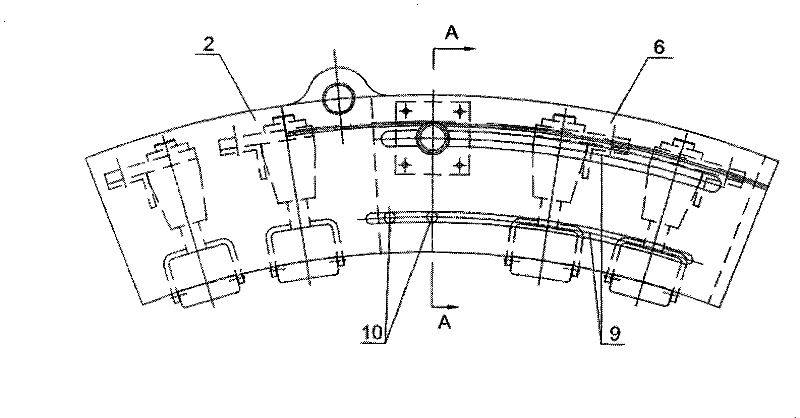

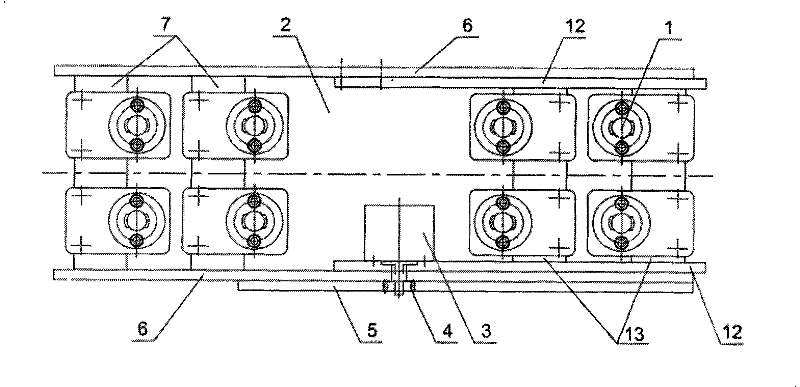

[0022] Such as Figure 1~6 As shown, the telescopic probe carrier of the present invention includes a probe 1 , and the probe 1 is fixed on the probe carrier 2 .

[0023] The above-mentioned probe carrier 2 is composed of a motor 3, a gear 4, an arc rack 5, a movable arc plate 6, a fixed arc plate 12 and a beam 7, 13, the motor 3 is fixed on the fixed arc plate 12, and the arc teeth The bar 5 is fixed on the movable arc-shaped plate 6, the gear 4 is installed on the shaft of the motor 3, and meshes with the arc-shaped rack 5, the two movable arc-shaped plates 6 and the beam 7 are connected to form a movable frame, and the two fixed arc-shaped The plate 12 and the crossbeam 13 are connected to form a fixed frame, the probe 1 is fixed on the crossbeam 7, 13, and is attached to the wheel tread 8, and the movable arc-shaped plate 6 has an arc-shaped guide groove 9, and there is a guide block in the arc-shaped guide groove 9 10. The movable frame and the fixed frame are connected ...

Embodiment 2

[0030] The telescopic probe carrier of the present invention, except that the driving device of the telescopic movement of the probe carrier 2 is a rotating cylinder, there is a guide block 10 in the arc guide groove 9, and there are 12 probes 1 on each probe carrier 2, the rest are all the same as Example 1 is the same.

Embodiment 3

[0032] The telescopic probe carrier of the present invention is the same as that of Embodiment 1 except that the driving device for the telescopic movement of the probe carrier 2 is a hydraulic motor, and there are 23 probes 1 on each probe carrier 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com