Aerosol aspirator, and its sucking method

An aspirator, aerosol technology, applied in the field of aerosol aspirator, can solve the problem of not being able to attract aerosol and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

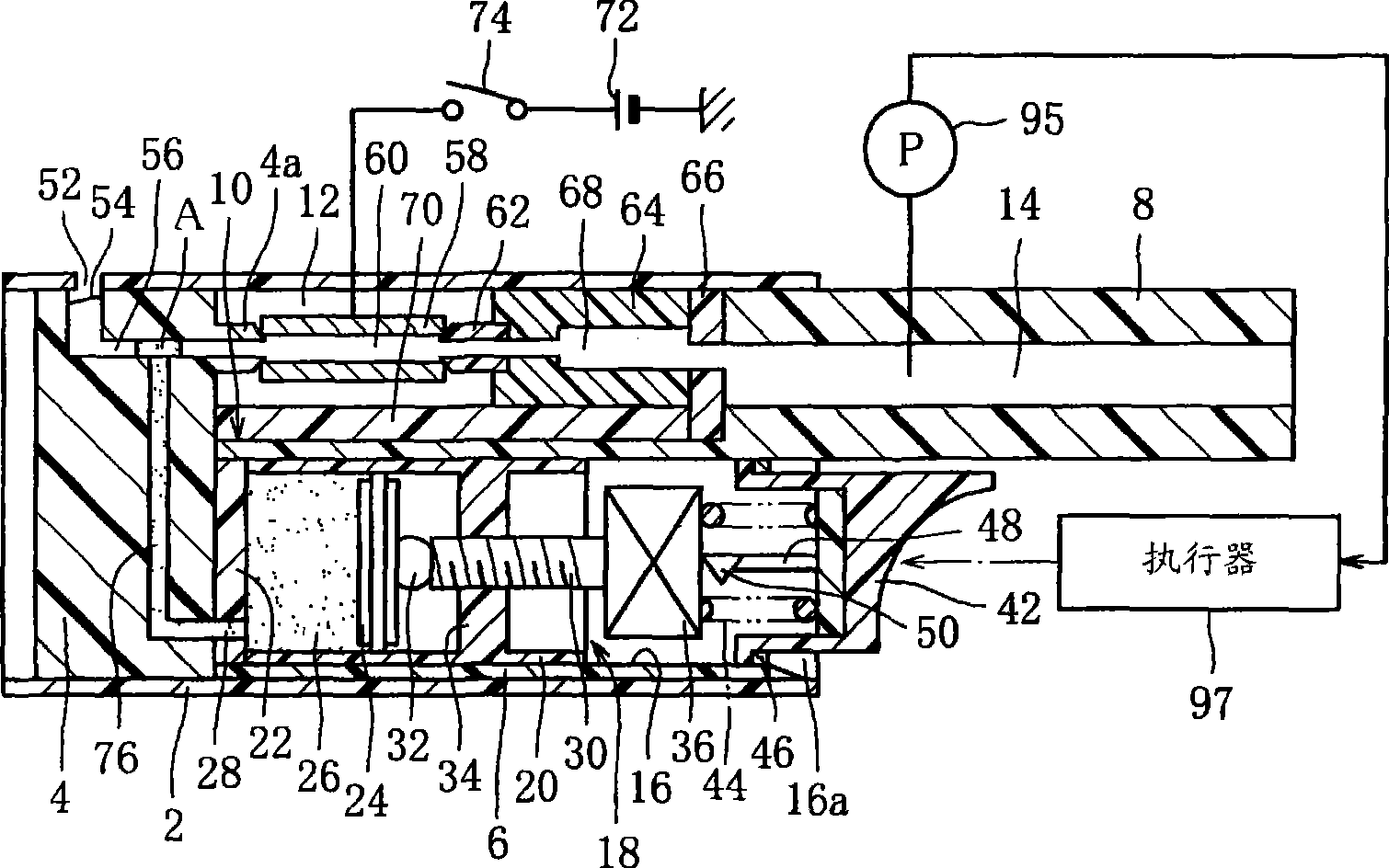

[0034] figure 1 It is a figure which shows the aerosol aspirator of 1st Example.

[0035] figure 1 The aspirator of the present invention has a housing 2 which is in the shape of a hollow cylinder with openings at both ends. An open end of the housing 2 is closed by an end wall 4 . A cylinder block 6 is embedded in the casing 2 , and a bottom of the cylinder block 6 abuts against the end wall 4 is provided at one end, and a tubular suction nozzle 8 is integrally provided at the other end. The suction nozzle 8 protrudes from the other open end of the housing 2 .

[0036] The cylinder block 6 has on its outer peripheral surface a depression 10 which extends from the bottom of the cylinder block 6 to the suction nozzle 8 . The recess 10 and the inner peripheral surface of the housing 2 jointly define a heating chamber 12 which communicates with an internal passage 14 of the suction nozzle 8 .

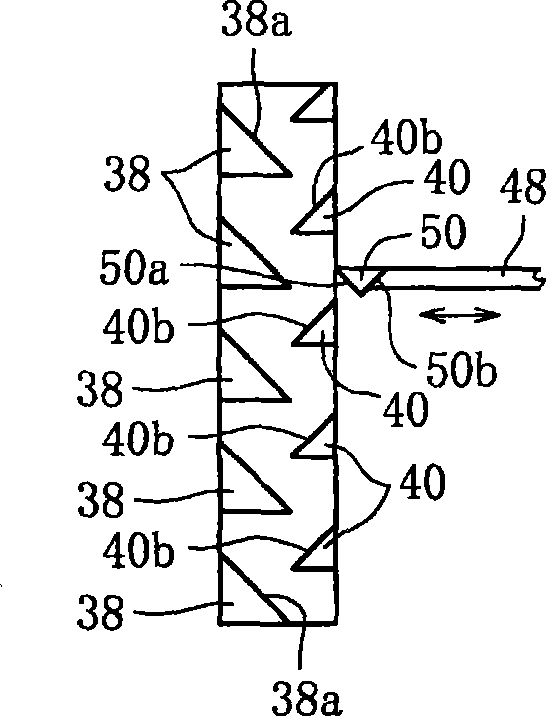

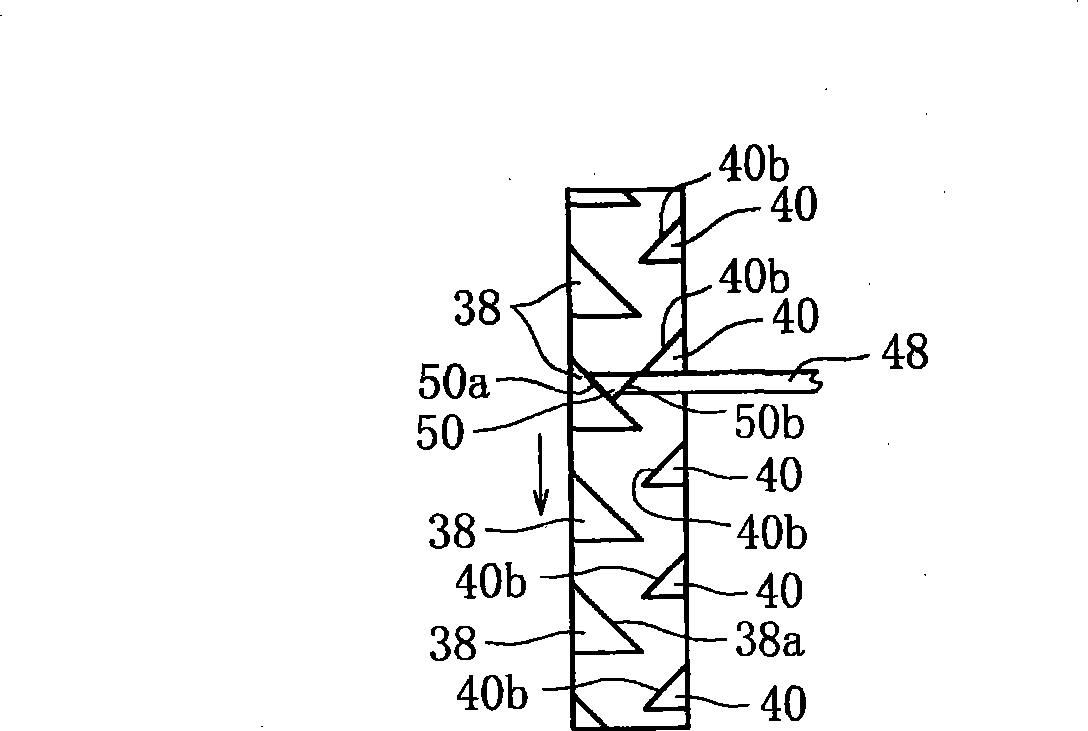

[0037] Furthermore, a cylinder bore 16 is formed in the cylinder block 6 . The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com