Reaction frame for self-balanced loading

A reaction force frame and self-balancing technology, which is applied in measuring devices, instruments, vibration testing and other directions, can solve problems such as space loading difficulties, and achieve the effect of solving difficult loading and clear force conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

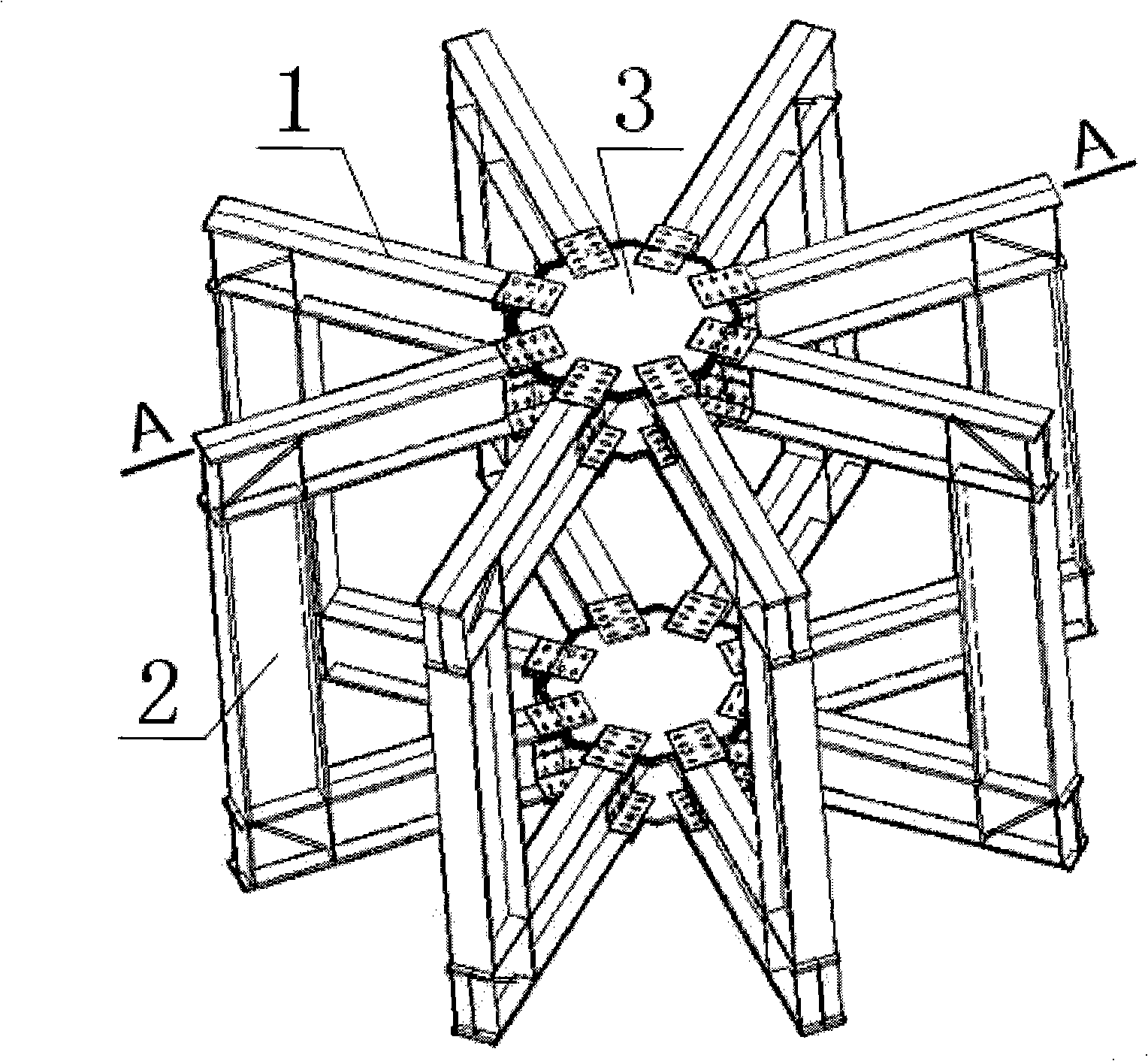

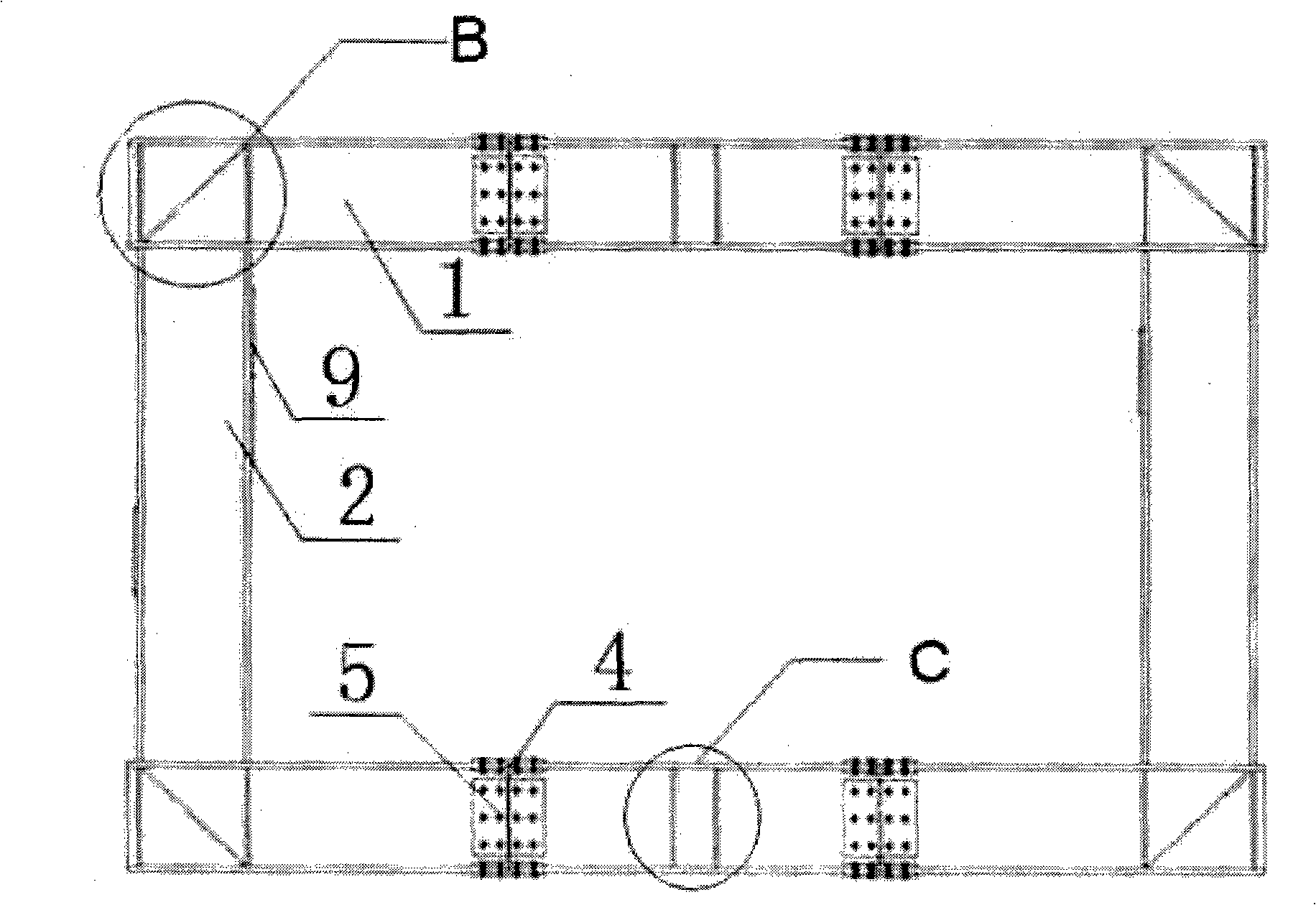

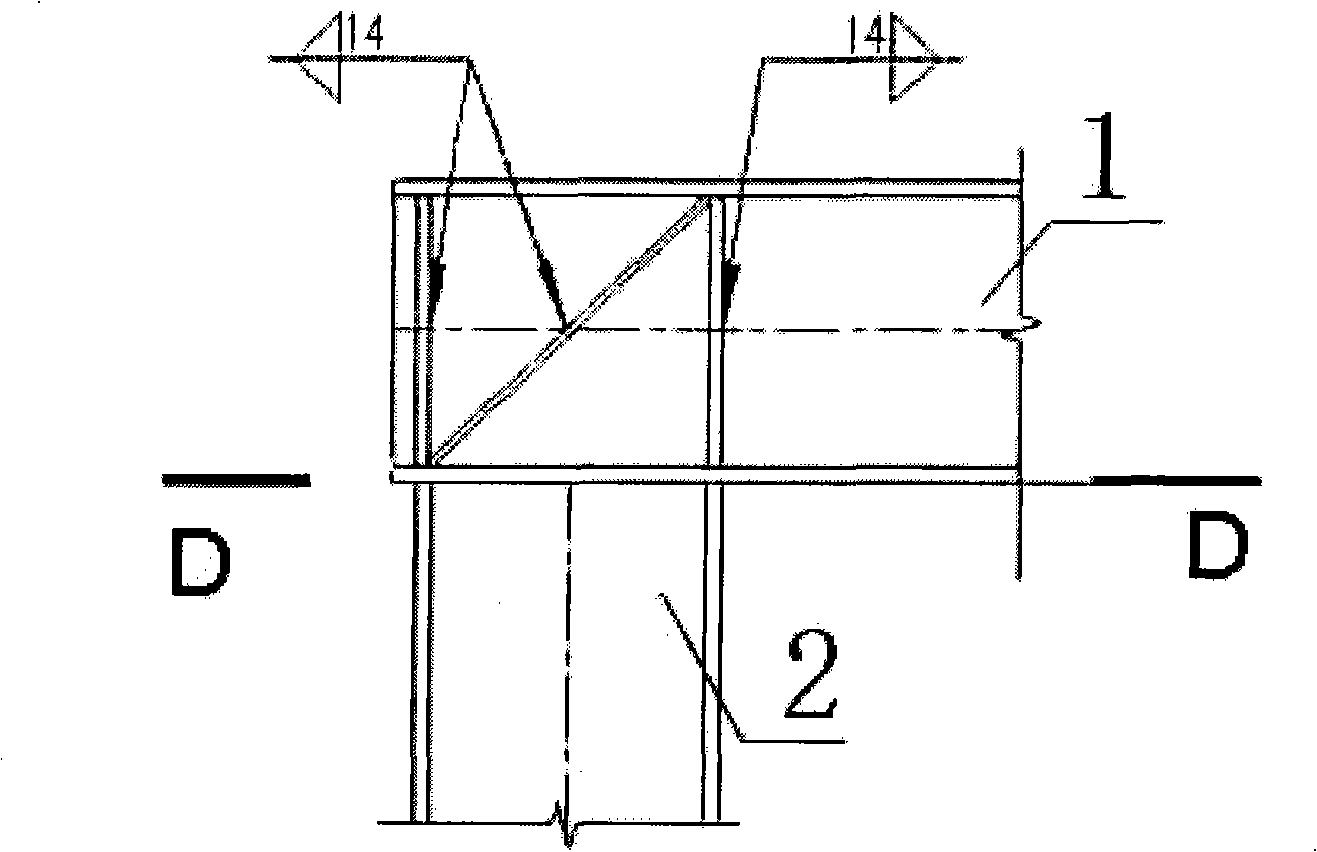

[0024] Such as figure 1 As shown, the self-balancing loading reaction frame includes a beam 1, a column 2 and an octagonal node 3. Beam 1 and column 2 are connected to each other by welding, such as image 3 , 4 shown. The beam 1 and the octagonal node 3 are connected by bolts, and there are three bolt connection positions, two at the upper and lower flanges of the beam, and one at the web, such as Figure 7 shown.

[0025] Both the beam 1 and the column 2 are made of H-shaped steel, and the beam and the column can be partially strengthened by stiffeners at the place where the reaction force is assumed during loading. The octagonal node 3 includes an octagonal steel plate 6, a circular tube 7 and a stiffener 8, such as Figure 4 shown. The upper and lower steel plates of the octagonal joint are welded to the upper and lower sides of the round pipe respectively, and stiffeners are evenly arranged on the bisection line of each side of the octagonal steel plate, and the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com