Improved fuser and image fixing member

An element, image fixing technology, applied in the field of making such fuser and fixing element, making and using fusing and fixing element, electrophotographic printing equipment, making such fuser and fixing element or other elements, capable of Solve problems such as fuser roll damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

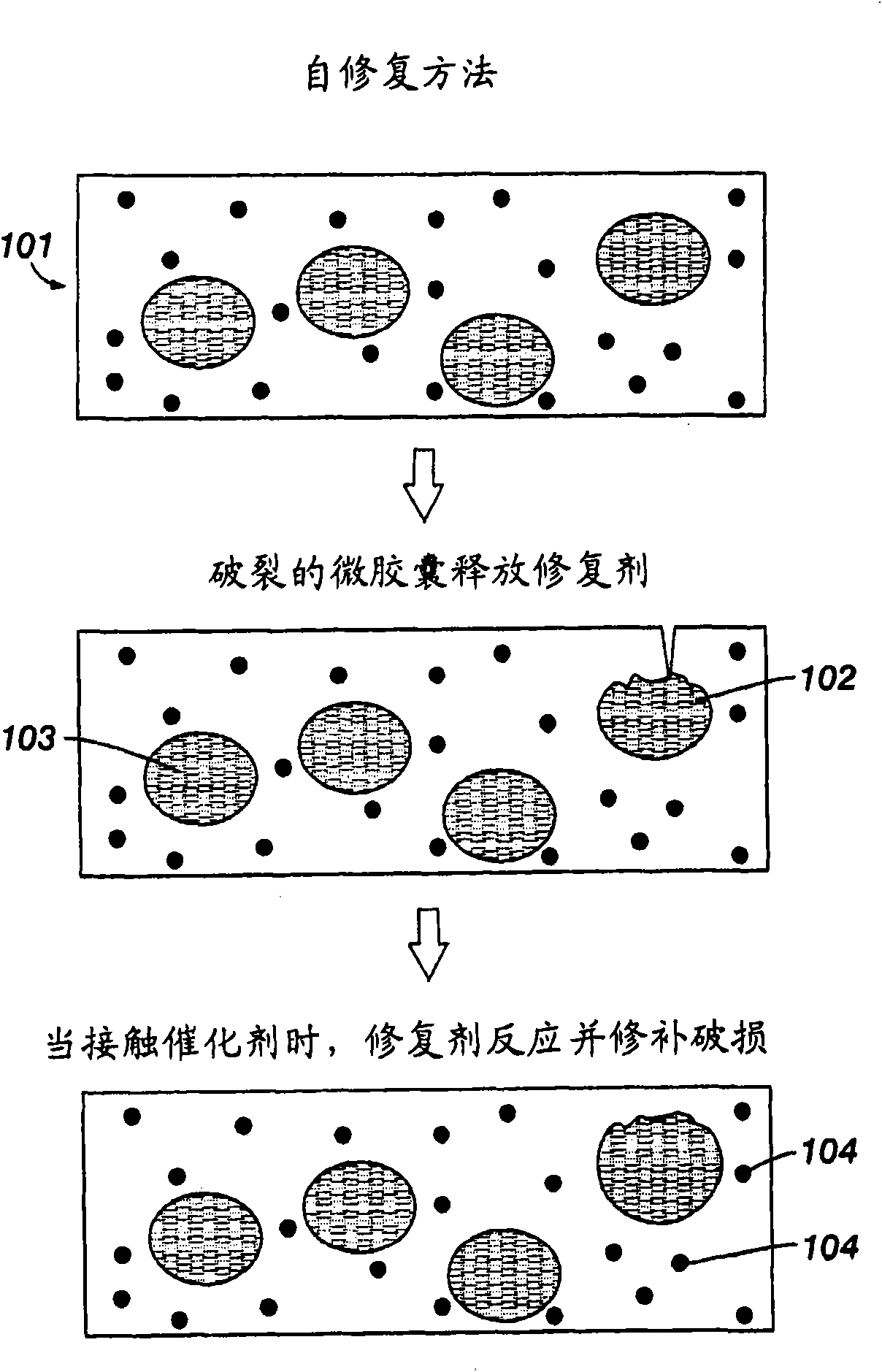

[0071] The microcapsules containing the restorative material can be prepared by any conventional method or by any other method obvious to the person skilled in the art, for example by encapsulation by in situ polymerization in an oil-in-water emulsion. The self-healing layer of the fuser element may be prepared by any conventional method or any other method apparent to those skilled in the art that will produce the desired coating.

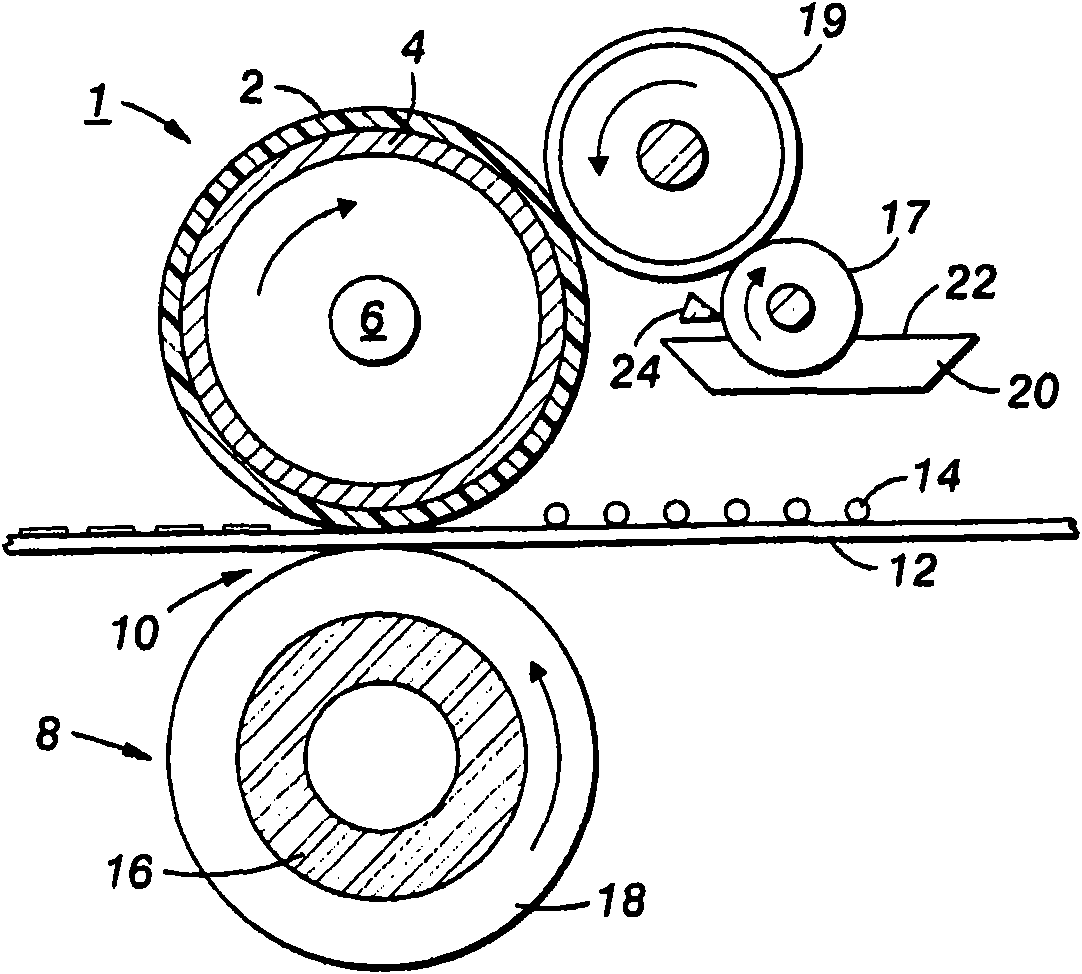

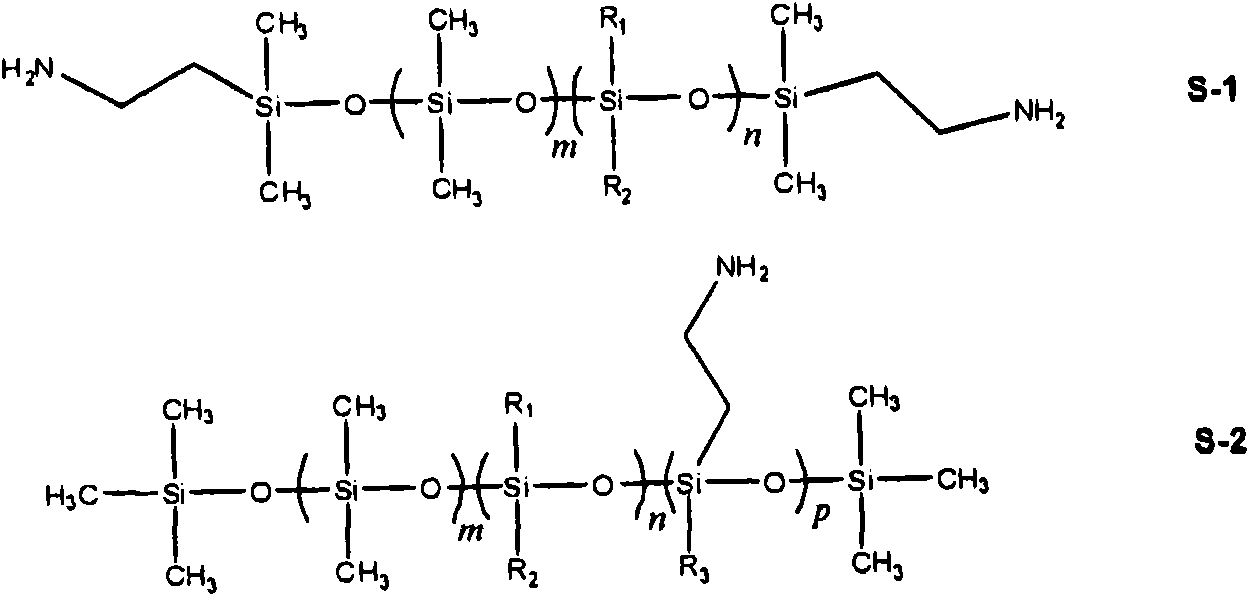

[0072] A fixing member incorporating microcapsules was prepared according to the following procedure. The coated melt was fabricated by coating a layer of VITON rubber and AO700 curing agent (N-(2-aminoethyl)-3-aminopropyltrimethoxysilane, available from United Chemical Technologies, Inc.) on the metal substrate. Roller. The fusing roll substrate was a cylindrical aluminum fusing roll core approximately 3 inches in diameter and 16 inches in length that was degreased, sandblasted, degreased and covered with a silane adhesive as described in US 5,3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com