Combine

A technology for combine harvesters and agricultural machinery, which is applied to harvesters, cutters, agricultural machinery and implements, etc. It can solve the problems of increasing operating mechanisms such as levers and complicating the mechanism, so as to prevent wrong operations, improve maneuverability, and improve The effect of cutting precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Next, embodiments of the invention will be described.

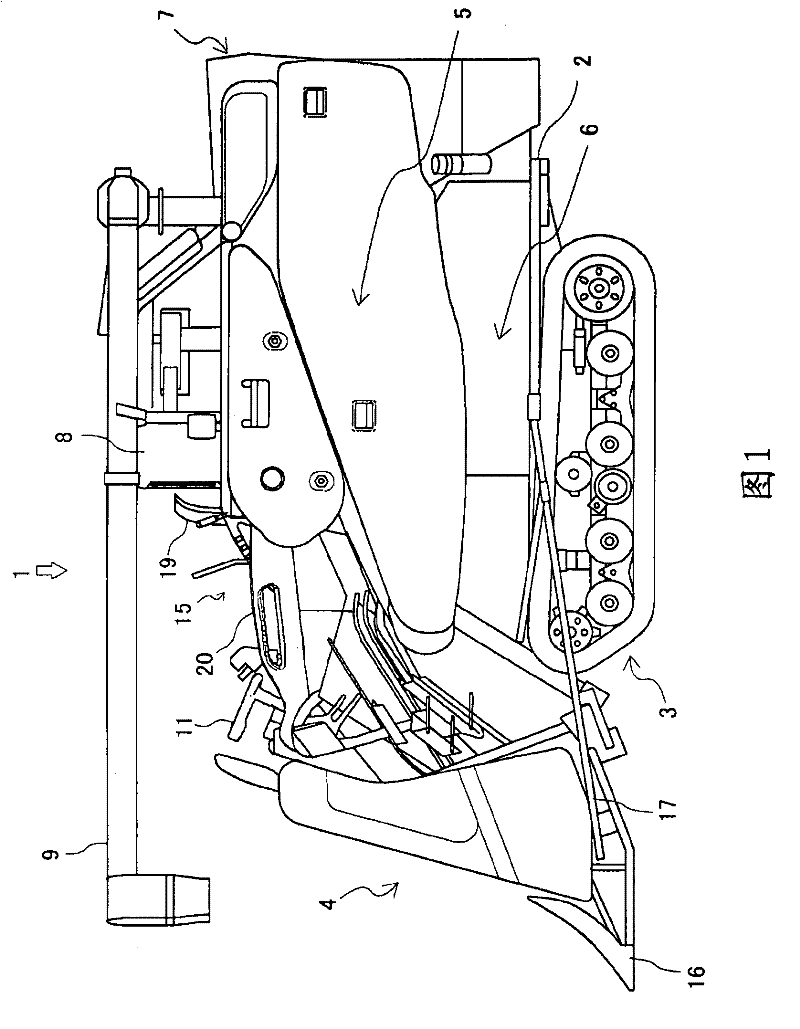

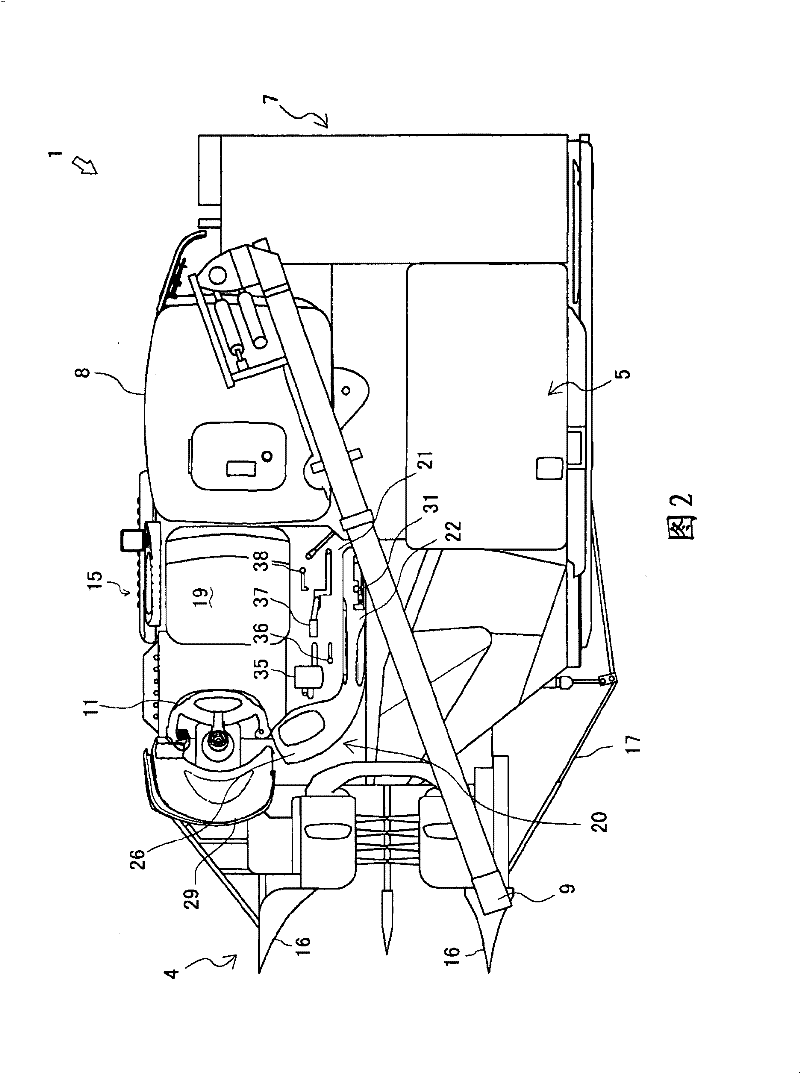

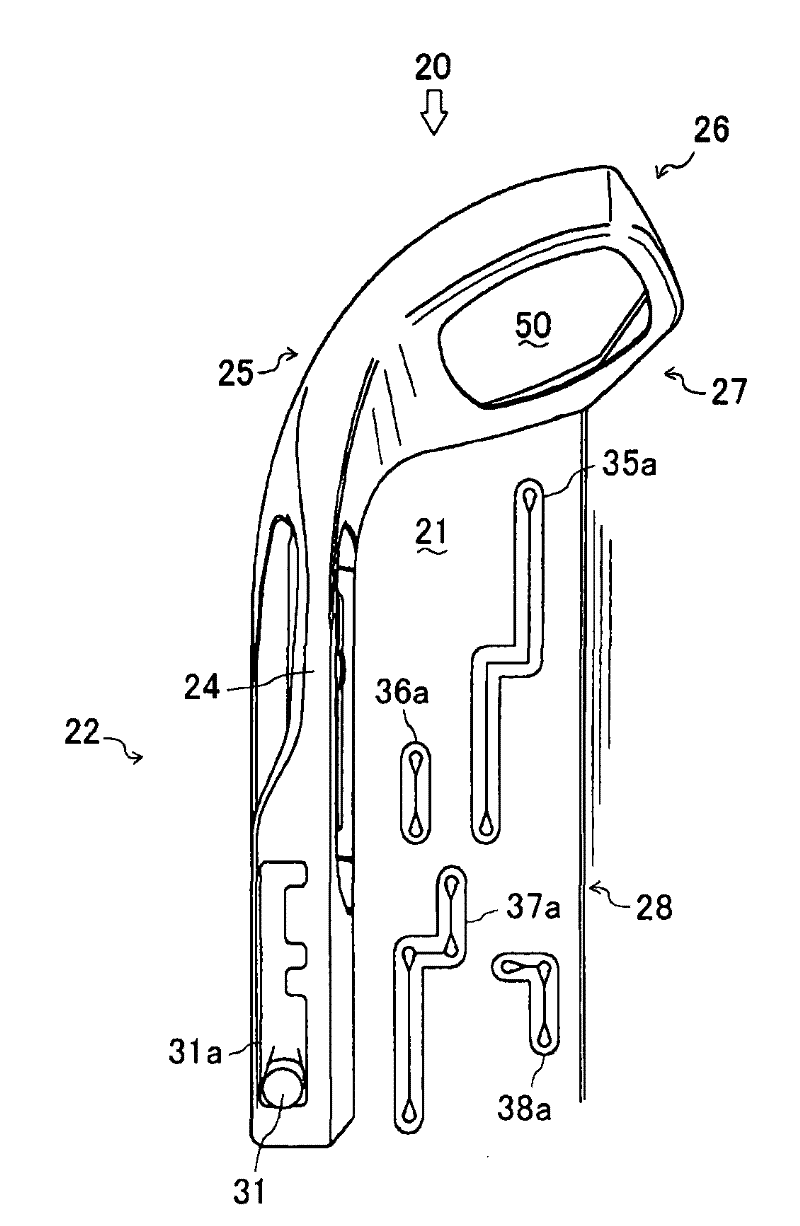

[0042] figure 1 It is a side view showing the overall structure of the combine according to the embodiment of the present invention, figure 2 It is a plan view showing the overall structure of the combine harvester according to the embodiment of the present invention, image 3 It is a plan view of the jamb related to the present invention. Figure 4 is a perspective view of a side column according to the present invention, Figure 5 It is a perspective view of the side column related to the present invention viewed from another angle.

[0043] First, use figure 1 and figure 2 The overall configuration of the combine harvester 1 will be described. In addition, in order to understand description easily, the advancing direction of the combine 1 will be demonstrated below as a front side.

[0044] Such as figure 1 , figure 2 As shown, the combine harvester 1 supports the body frame 2 with left and right cra...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap