Polysulfide curable composition

A technology for curable compositions and polymers, applied in the field of curable compositions, can solve the problems of fast thickening speed, adverse effects of foaming, reduced operability, etc., and achieve the effect of sufficient service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4 and comparative example 1~3

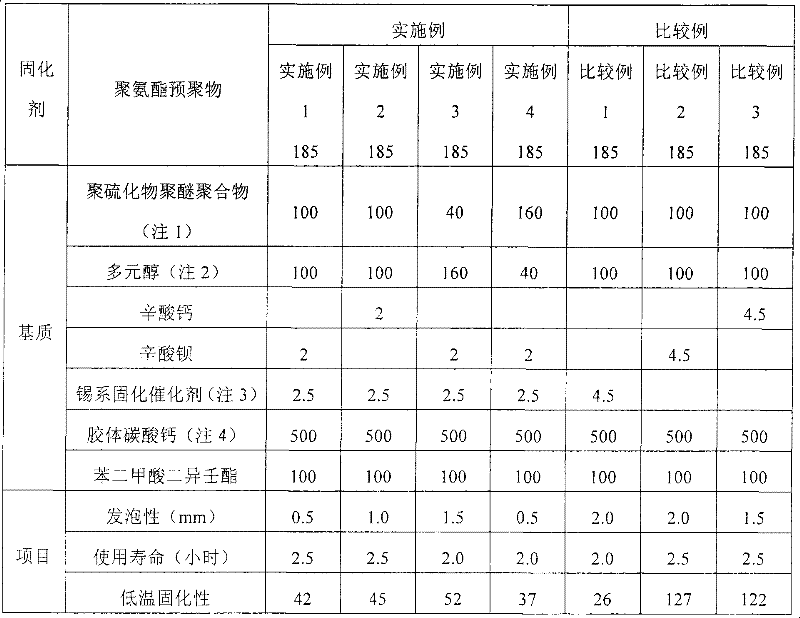

[0066] The base and the curing agent were uniformly mixed using the components in parts by weight shown in Table 1 below to produce a polysulfide composition. Among them, the polyurethane prepolymer in Table 1 is obtained by mixing polypropylene glycol and xylylene diisocyanate to a (NCO) / (OH) of 1.85 and reacting at 80°C for 14 hours. The NCO content is 3.0 %, the viscosity is 16000mPa·s.

[0067] The obtained polysulfide compositions were submitted to performance tests respectively, and the results were recorded in Table 1.

[0068] [Evaluation method]

[0069] 1. Foaming

[0070] The mixed matrix and curing agent were weighed at a weight ratio of 100:23, filled into a 45mm×h18mm cylindrical container (material: polypropylene), and placed in an atmosphere of 50°C for 24 hours, and then the sealing material swelled out of the container was measured The foaming height of the cured product.

[0071] 2. Service life

[0072] The matrix and curing agent are mixed, and the polymer sheet i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com