Sealant for display and liquid crystal display using the same

A display and encapsulant technology, applied in the direction of instruments, adhesives, adhesive types, etc., can solve the problems of poor display, poor adhesion of liquid crystal sealants and alignment films, and reduced moisture resistance reliability, and achieve long-term reliability. Excellent resistance to heat and humidity, excellent reliability, and the effect of ensuring the degree of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

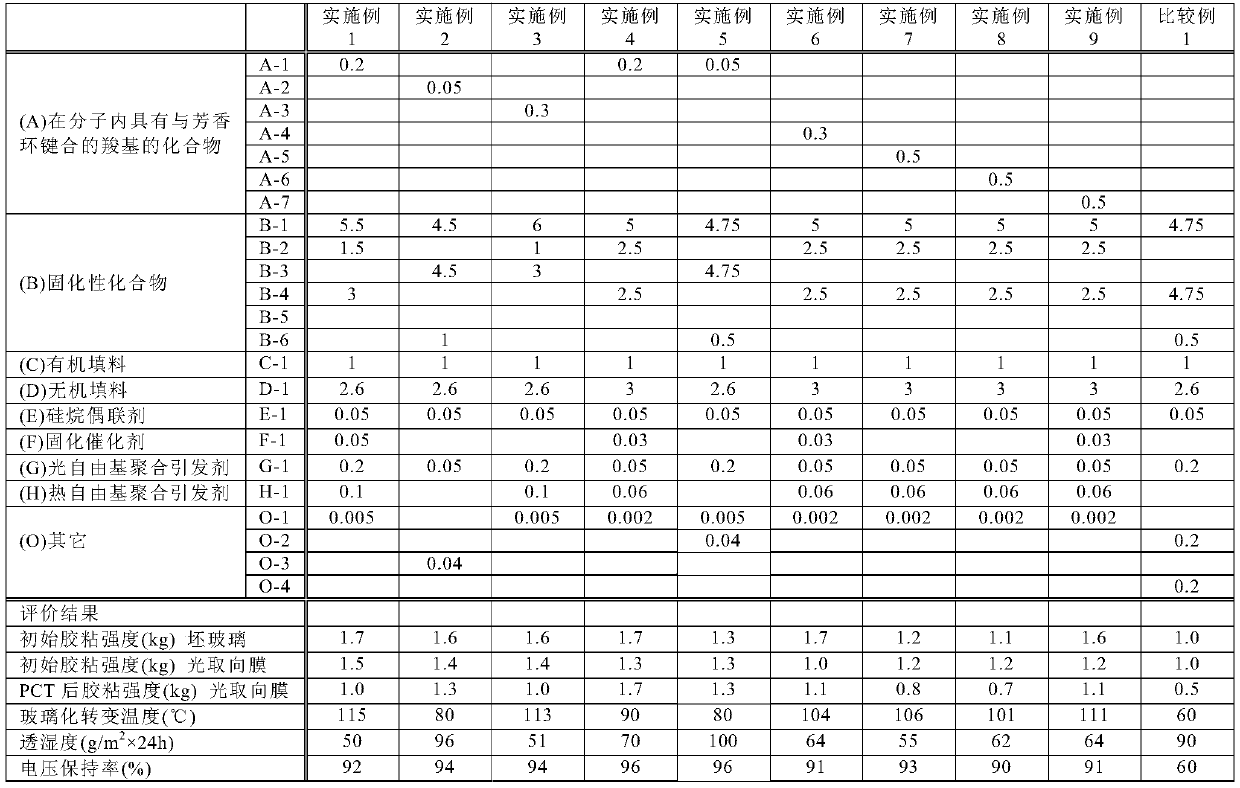

Embodiment 1~9、 comparative example 1

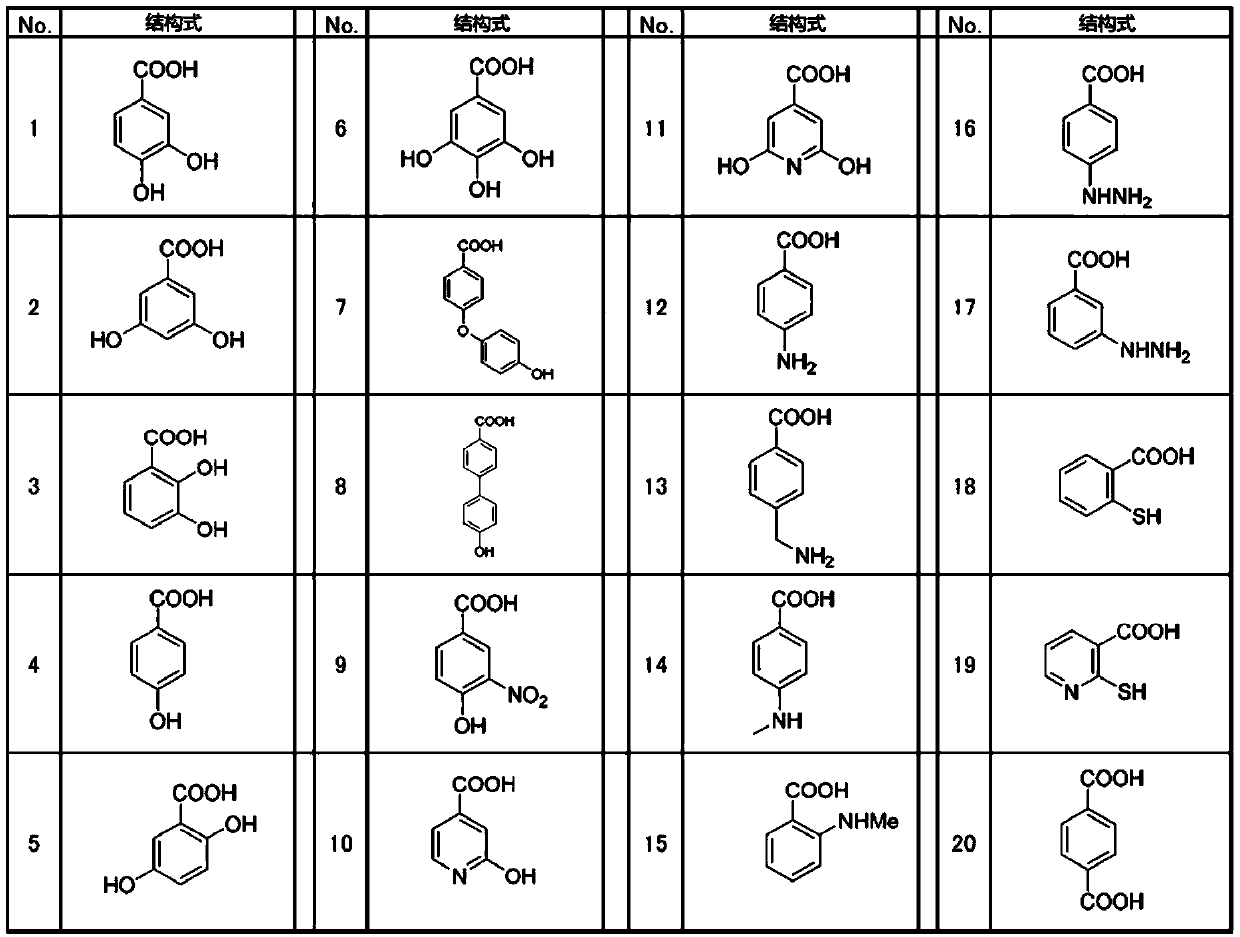

[0102] Heat and dissolve components (B) and (G) at 90°C in the proportions shown in Table 1 below, then cool to room temperature, and add components (A), (C), (D), (E), (F ), (H), were stirred, then dispersed by a three-roll machine, and filtered with a metal mesh (635 mesh), thereby preparing Examples 1-9 of the encapsulant for a display. Moreover, the comparative example 1 was prepared using component (O-4) instead of component (A).

[0103] [Evaluation]

[0104] [Adhesive Strength]

[0105] (Initial Adhesive Strength Blank Glass (Sugaras))

[0106] 1 g of glass fibers of 5 μm was added as a spacer to 100 g of liquid crystal sealing compound produced in an example and a comparative example, and mixed and stirred. Apply this liquid crystal sealant on a glass substrate in such a way that the corners of 1 cm x 1 cm are replicated, bond the facing glass substrates, and irradiate 3000 mJ / cm with a UV irradiation machine 2 UV rays, then put into an oven and thermally cured at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Line width | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com